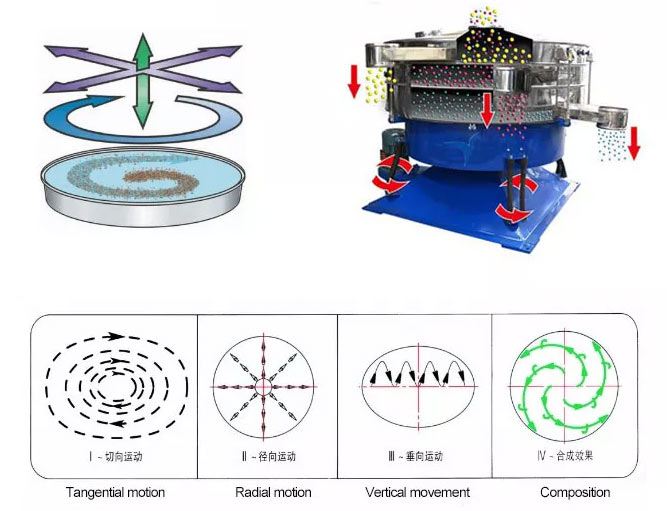

The circular tumbler screen combines sieving (circular motion) and hand sieving (parabolic motion), which can be used for the separation and dust removal of powdery and granular products, and the sieving accuracy can reach more than 95%.

After the power is turned on, the screen body starts, and the screen box is driven by the vibrating device to perform approximate circular motion. At this time, the screen box drives the entire screen surface to perform periodic motion, and the materials on the screen surface follow the screen box to perform directional jumping motion on the screen surface. , In this process, the material smaller than the sieve hole falls to the lower layer of the screen and is discharged from the lower discharge port, and the material larger than the sieve hole is discharged from the upper discharge port to complete the entire screening work.

1. Imitation of manual screening, the screened product is a displacement movement on the screen platform, the material landing time is usually above 85%, and the screening efficiency can reach above 95%.

2. The size of the machine ranges from 600-1000-1200-1600-2000-2400 and the diameter is 2600 mm, the output is 5-10 times that of ordinary vibrating screen

3. 5 layers of screens can be installed, which can complete the separation of 2-6 different sizes.

4. The moving parts swing left and right instead of swinging up and down like a vibrating screen, thereby reducing the noise level and reducing the damage to the screened product at the same time.

5. Different cleaning devices can be used flexibly, such as bouncing balls, cleaning brushes, ultrasonic screening, etc., to avoid material clogging.

The circular tumbler screen is used for screening, grading, and dust removal of dry, powdery, and granular products, especially for high-yield, multi-layer sorting of fine, fragile, irregular, and light products that are difficult to screen.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.