5-10 Times The Output, Ultra-Fine Powder,No Mesh Blocking

![]()

![]()

![]()

Price:$860.00-$3,680.00/set

Consult now and enjoy a 10% discount

Application: Screening of ultrafine powders that are prone to static electricity, agglomeration and light specific gravity

Layers: 1~5 layers

Model: YBS800/1000/1200/1600/2000/2500

Mesh: 10-600 mesh (0.023mm) Output: 1~80t/h

Material: 304/316L stainless steel, carbon steel, contact part stainless steel

Customizable:

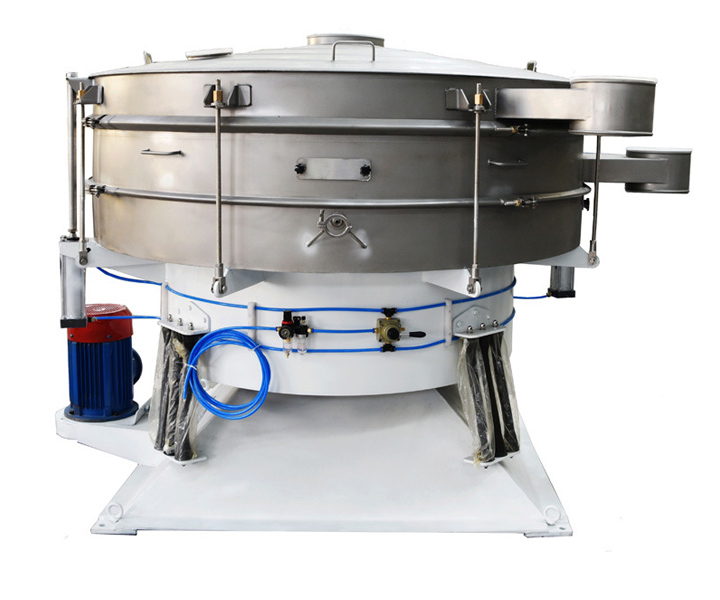

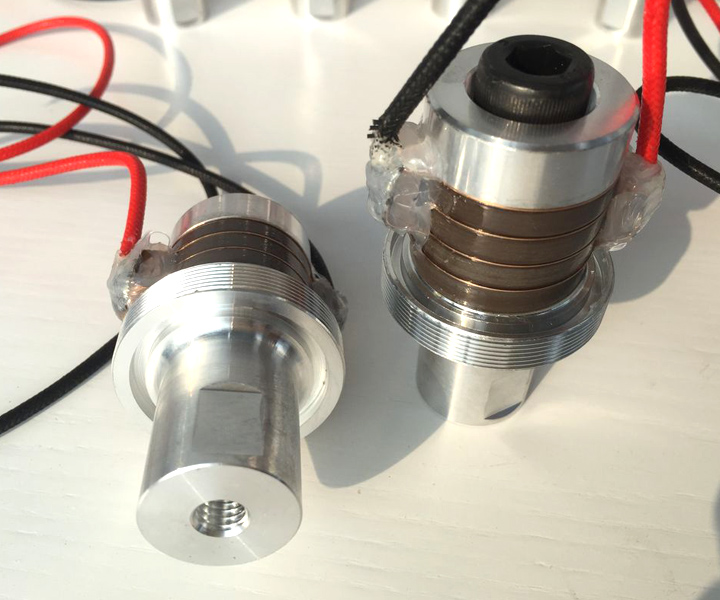

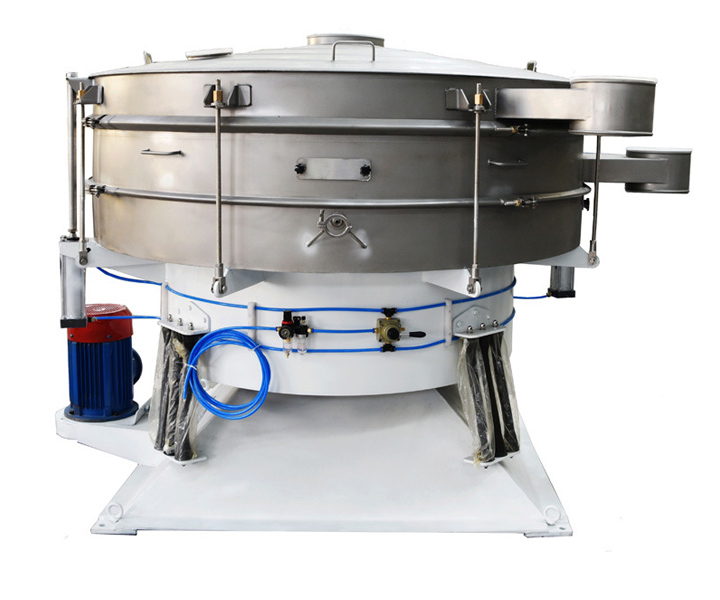

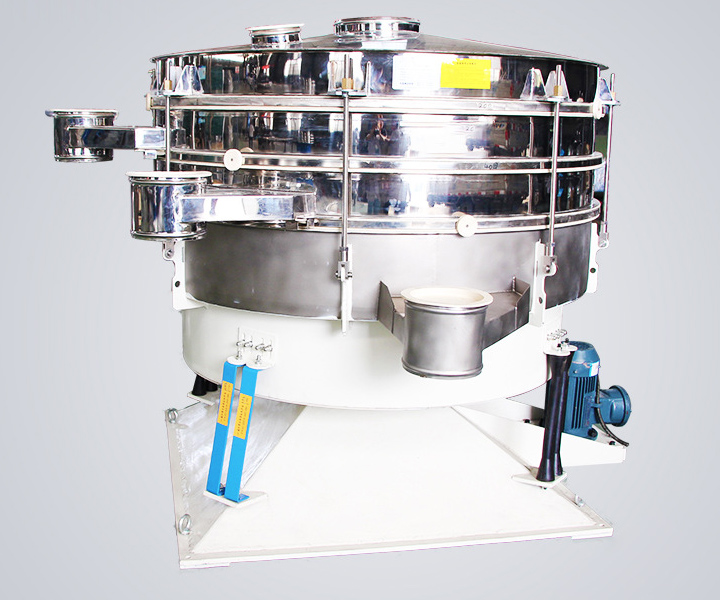

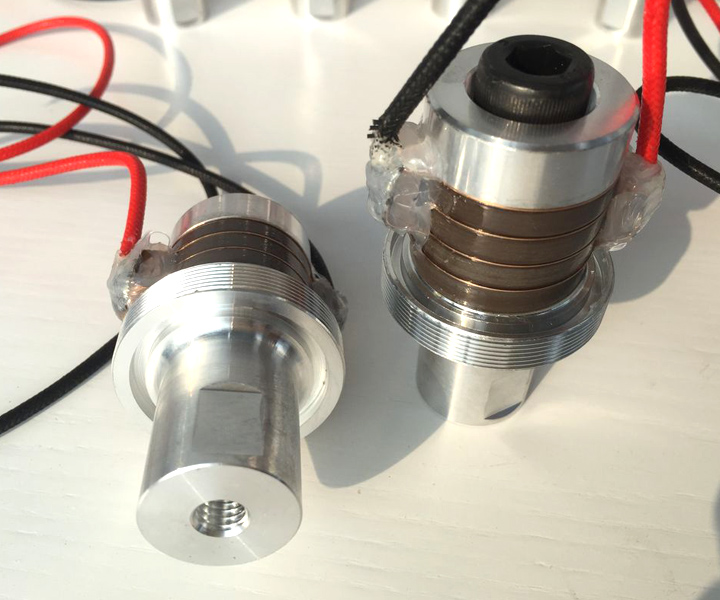

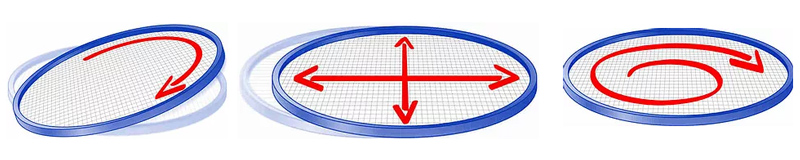

The ultrasonic swinging screen is based on the ordinary swinging screen, adding an ultrasonic device, and transforming the screen mesh frame. The electric power input by the ultrasonic power supply of the ultrasonic transducer device is converted into a mechanical power of 36,000 times per second and then transmitted. It can speed up the powder penetration speed and penetration rate. The screen is designed with a sticky mesh structure, which can make the vibration wave transmit more evenly and the screen is firmer. It is especially suitable for strong adsorption, high viscosity, high static electricity, high density, super The fine powder is sieved.

As a kind of swinging screen, ultrasonic swinging screen also has the principle of imitating artificial screening. At the same time, ultrasonic swinging screen is equipped with ultrasonic system, which uses transducer to convert ultrasonic wave energy into mechanical energy and transmit it to the screen surface, which can vibrate every second. 36,000 times, not only can effectively break up the agglomerated powder, but also make the material beat more frequently, almost showing a low-altitude suspension state, speed up the speed of material penetration, and improve screening efficiency and output.

1. High efficiency: The ultrasonic system enables the material to penetrate the mesh quickly, the output is more than 10 times that of the ordinary vibrating screen, and the accuracy is more than 98%;

2. Easily sieve ultrafine powder: the installed ultrasonic system can solve the screening problems such as material clumping and static electricity;

3. No net blocking: The ultrasonic device has its own net cleaning function, and there is no need to install other net cleaning pinballs, so as to avoid the pollution of materials caused by wear and tear;

4. Clean and hygienic: In order to avoid dusting of the sieved powder materials, the sieve machine is equipped with a sealing ring and a dust cover, which has good sealing performance.

| Material | MESH | Production Capacity (kg/h) |

Model |

| Rubber Powder | 24 | 1000 | YBS-2000-2S |

| Oil Coke Powder | 110-120 | 3000 | YBS-1500-2S |

| Panax Notoginseng Powder | 100 | 300 | YBS-600-4S |

| Quartz Flour | 100-200 | 4500 | YBS-1500-2S |

| Chinese Medicine Powder | 325 | 600 | YBS-600-4S |

| Forage | 40 | 2200 | YBS-1500-2S |

| Cocoa Powder | 300 | 800 | YBS-800-4S |

| Ground Coffee | 20-80 | 400-800 | YBS-600-2S |

| Model | Diameter (mm) |

Screen area (m²) |

Feeding size (mm) |

Screening size (mm) |

Capacity (t/h) |

Amplitude ((mm) |

Power (kW) |

| YBS800 | 800 | 0.29 | ≤25 | 0.073-3 | 6-10 | 5-8 | 0.75 |

| YBS1000 | 1000 | 0.71 | 8-15 | 1.5 | |||

| YBS1200 | 1200 | 1.11 | 15-30 | 2.2 | |||

| YBS1600 | 1600 | 1.83 | 25-40 | 3 | |||

| YBS2000 | 2000 | 2.62 | 30-50 | 4 | |||

| YBS2500 | 2500 | 4.61 | 40-60 | 5.5 |

The ultrasonic rocking screen is composed of feed port, screen box, screen mesh, discharge port, transducer device, ultrasonic system, spindle, shaft chamber, balance block, spring group, conical base and motor from top to bottom.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.