Vertical screw conveyor

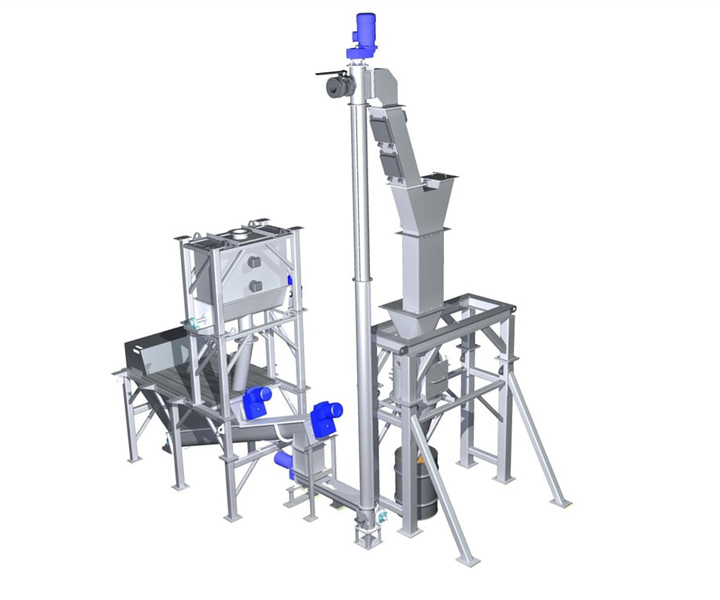

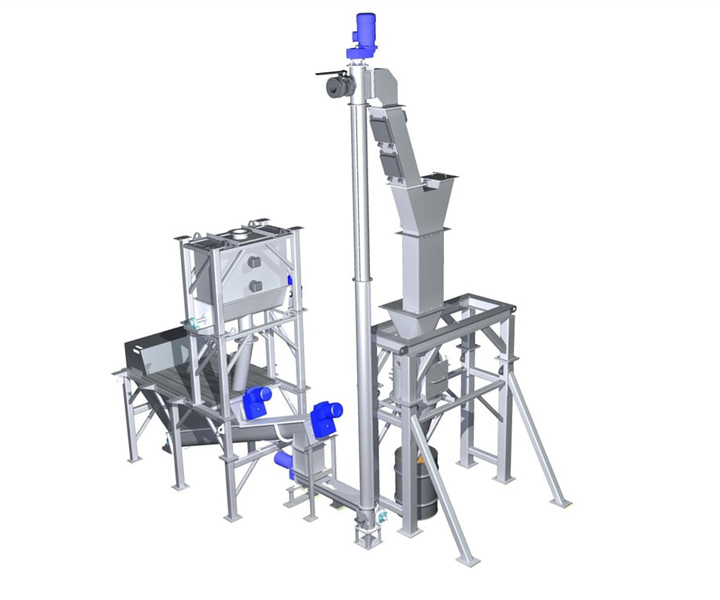

Vertical screw conveyor Stainless steel vertical screw conveyor

Stainless steel vertical screw conveyor Carbon steel vertical screw conveyor

Carbon steel vertical screw conveyor Mobile vertical screw conveyor

Mobile vertical screw conveyor Flexible vertical screw conveyor

Flexible vertical screw conveyor

For vertical conveying and lifting/loading of powder to desired height

![]()

![]()

![]()

Price:$500.00-$5,000.00/Set

Consult now and enjoy a 10% discount

Diameter: 114mm-800mm

Conveying height: ≤6 meters

Capacity: 7-300m3/h

Speed: 200-315rpm

Motor power: 2.2-18.5 kw

Application: Bulk material taken from a silo, hopper, conveying or feeding device can be discharged via a vertical screw into a weigh hopper, one or more silos or silos, or another conveyor or conveying system.

Commitment:

Vertical screw conveyor is a continuous conveying equipment that utilizes the forced feeding screw to rotate and convey materials. It is suitable for conveying powdery, granular and non-sticky materials vertically or at a large angle. It can lift/load powder or granules to a certain height. Inside the hopper or silo, with a vertical height of up to 8 meters, the small footprint allows it to fit into almost any plant layout.

The forced feeding of the vertical screw conveyor adopts a circuitous feeding type. The feeding port of this form is connected with the casing of the vertical screw conveyor at 90°, which is suitable for materials with poor fluidity. In terms of the arrangement of the driving device, there are generally two types of arrangements: top drive, which is suitable for occasions with low conveying height, which occupies a small area, and bottom drive, which is suitable for occasions with high conveying height, which occupies a large area.

1. Different materials

Carbon Steel Vertical Screw Conveyor: Mainly used in cement, coal, stone and other industries with large wear and no special requirements for hygiene.

Stainless steel vertical screw conveyor: suitable for industries such as grain, chemical industry, food and other industries that have requirements on the conveying environment, high cleanliness, no pollution to materials, long use time, and relatively high cost.

2. According to the driving method

Single motor drive: When the motor power is less than or equal to 15Kw, the single drive type is adopted.

Dual motor drive: When the motor power is greater than 15Kw, the dual drive type is adopted.

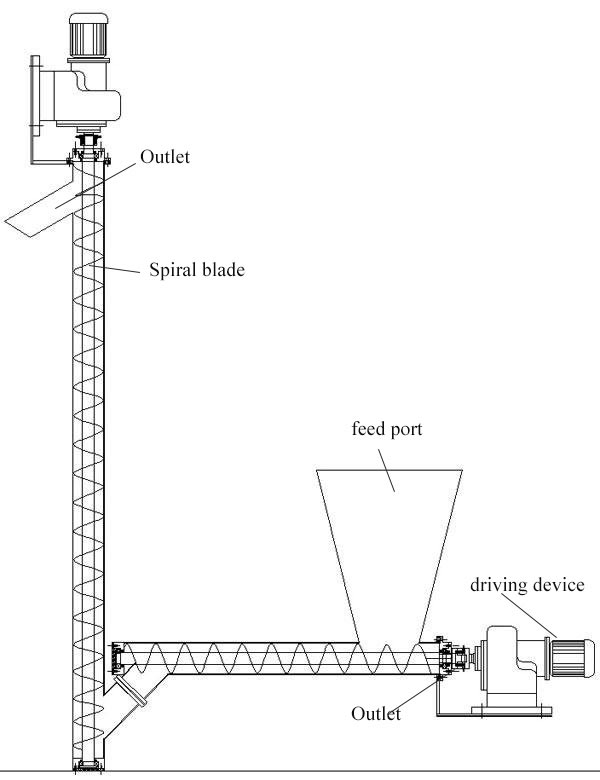

The product rotates with the screw at high speed, and the material to be conveyed is added from the feed port of the horizontal part, and is fed into the conveyor and the vertical part by the rotating horizontal feed screw, and then the material is pushed up to the discharge port by the vertical screw, The material rotates at a high speed with the screw, and the material to be conveyed is added from the feed port of the horizontal part, enters the conveyor through the rotating horizontal feed screw, and then pushes the material to the discharge port by the vertical screw to be discharged.

Vertical screw conveyor for feed

Vertical screw conveyor for corn flour

Vertical screw conveyors offer many advantages over other options:

Lifting height up to 8 meters

For transporting product in tall rooms or small silos (up to 8m height difference), when increased lift height is required, intermediate hangers or stabilizer bearings are often required to eliminate excessive helical deflection and "whipping".

Available in many configurations

The inlet section can be biased to either side or in series, requiring a horizontal infeed conveyor to precisely meter bulk material directly to the inlet of a vertical conveyor for maximum efficiency.

Uniform feeding, no blockage

High-power vibration motor (3.5kw-11kw), high speed (60-140 rpm/min), to ensure fast and even delivery.

Lowest number of spare parts

Possibility to reduce or expand installed screw feeders due to the interchangeability of our parts.

Sealing system

The material entry is carried out entirely through the independent back flow of the material in the closed pipeline, which meets the dustproof requirements and fully improves the conveying environment.

Small footprint

Compared to bucket elevators or pneumatic conveying systems, vertical screw conveyors have the most compact overall dimensions and are suitable for almost any plant layout.

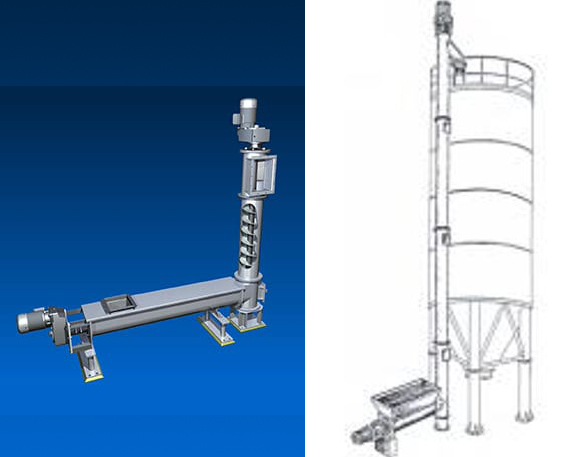

The vertical screw conveyor is composed of horizontal screw conveyor and vertical screw conveyor.

Driving device: adopt the upper driving form. The motor is installed on the head of the main machine, and the power is transmitted to the main shaft through the belt, so as to drive the screw to run. When the motor power is less than or equal to 15Kw, single drive is used, and when the motor power is greater than 15Kw, double drive is used.

Spiral: According to the different materials conveyed by the vertical screw conveyor, the surface type of the spiral blade has a solid surface type, a belt type surface type, and a blade surface type.

Bearing: There is a thrust bearing at the end of the screw shaft in the direction of material movement to give the screw axial reaction force along with the material. When the machine length is long, an intermediate suspension bearing should be added.

Feed trough: The trough is made of carbon steel and stainless steel, but it is usually made of thin steel plate with a thickness of 2 to 4mm. The two sides of the cross section are vertical and the bottom is semicircular.

The feeding of the vertical screw conveyor must maintain the necessary feeding force. When the feeding height difference is small, the vertical screw conveyor is equipped with a horizontal feeding screw. Generally, the horizontal feeding screw and the vertical conveying screw are made into a whole. The diameter of the horizontal feeding screw is the same as that of the vertical feeding screw, and the rotation speed of the horizontal feeding screw is lower than that of the vertical feeding screw.

| Specification | LC160 | LC200 | LC250 | LC315 | |

| Diameter(mm) | 160 | 200 | 250 | 315 | |

| Rotating Speed(r/min) | 450 | 450 | 415 | 380 | |

| Capacity(m3/h) | 10 | 28.5 | 51 | 95 | |

| Conveying Height(m) | 2.5~15 | 2.5~15 | 2.5~15 | 2.5~15 | |

| Motor | Height(m) | 2.5~5.5 | 2.5~5.5 | 2.5~4 | 2.5~4 |

| Model | Y100L2-4 | Y100L2-4 | Y132M1-6 | Y160M-6 | |

| Power | 3KW | 3KW | 4KW | 7.5KW | |

| Height(m) | 6~7 | 6~7 | 4.5~5.6 | 4.5~6 | |

| Model | Y112M-4 | Y112M-4 | Y132M2-6 | Y160L-6 | |

| Power | 4KW | 4KW | 5.5KW | 11KW | |

| Height(m) | 7.5~10 | 7.5~10 | 6~7.5 | 6.5~8 | |

| Model | Y132S-4 | Y132S-4 | Y160L-6 | Y160L-6 | |

| Power | 5.5KW | 5.5KW | 7.5KW | 15KW | |

| Height(m) | 10.5~13.5 | 10.5~13.5 | 8~11 | 8.5~12 | |

| Model | Y132S-4 | Y132M-4 | Y160L-6 | Y180L-6 | |

| Power | 7.5KW | 7.5KW | 11KW | 11KW2台 | |

| Height(m) | 14~15 | 14~15 | 11.5~15 | 12.5~15 | |

| Model | Y160M-4 | Y160M-4 | Y180L-6 | Y180L-6 | |

| Power | 11KW | 11KW | 15KW | 15KW2台 | |

| VERTICAL SCREW CONVEYORS - DIMENSION TABLE | |||||||

| Ø C | |||||||

| 114 | 139 | 168 | 193 | 219 | 273 | 323 | |

| A | 150 | 170 | 185 | 200 | 235 | 260 | |

| L | Variable on demand | Variable on demand | Variable on demand | ||||

| min.800 | min.1500 | min.2000 | |||||

| M | 330 | 330 | 460 | 460 | 520 | 520 | 670 |

| E | 120 | 130 | 160 | 175 | 190 | 215 | 240 |

| F | 150 | 150 | 200 | 200 | 200 | 200 | 200 |

| G | 350 | 350 | 440 | 440 | 500 | 550 | 550 |

| H | Variable on demand | ||||||

| W | 215 | 215 | 285 | 285 | 355 | 355 | 355 | U x V | 155x90 | 155x90 | 205x125 | 205x125 | 205x160 | 205x160 | 255x200 |

| T | Variable, max. 1040 | Variable, max. 1390 | Variable, max. 1600 | ||||

| Z | Variable, max. 515 | Variable, max. 690 | Variable, max. 890 | ||||

| Screw Diameter (Inches) |

Capacity (Cubic Feet per Hour) |

Recommended Horizontal Feeder |

| 6 | 400 | 179 |

| 9 | 1,300 | 162 |

| 12 | 3,000 | 160 |

| 16 | 6,000 | 127 |

1. Length combination: The height of the vertical screw conveyor (ordering height) refers to the distance between the feeding port and the discharging port.

2. Driving device: the upper driving type is adopted. The motor is installed on the head of the main machine, and the power is transmitted to the main shaft through the belt, thereby driving the screw to run.

Type 200 and Type 250 are provided with a single drive type, and the maximum configuration motor power is 15Kw; Type 315 is provided with two types of single drive and double drive. The forced feeding device is equipped with a driving device installed on the ground, which should be designed by the manufacturer. If the user designs it, the user is responsible for it.

The formula for calculating the delivery volume:

Q=8.007•D•3n (m3/n) In the formula: Q=delivery amount (m3/n); D=screw diameter (m); n=screw speed (r/min).

Motor power calculation formula: N=0.015258856Q•r•H (Kw) where: N=motor power (Kw); Q=conveying volume (m3/n); r=material bulk density (t/m3); H=feed The distance (m ) between the material port and the material outlet.

Vertical Screw Conveyor Capacity&Horsepower Calculation

| Capacity, Sizing, and Speed Table | ||

| Vertical Screw Conveyor Diameter (Inches) |

Maximum Recommended Capacity (Cubic Feet per Hour) |

Recommended Speed Range (RPM) |

| 6 | 400 | 200-215 |

| 9 | 1300 | 200-215 |

| 12 | 3000 | 165-180 |

| 16 | 6000 | 135-150 |

Vertical screw conveyors are an efficient way to lift a wide variety of bulk materials from steep slopes to full vertical, ideal for handling dry to semi-fluid materials ranging from free-flowing to slightly sluggish, requiring horizontal infeed conveyors to accurately meter bulk materials directly to the vertical Conveyor inlet for maximum efficiency, offering a compact design so it does not take up a lot of floor space, suitable for most plant layouts.

| materials | Lifting height(meters) | Conveying capacity (t/h) | model |

| Sand | 6 | 6 | LC273 |

| Iron oxide | 7 | 1 | LC219 |

| coffee powder | 4 | 1 | LC159 |

| Soybeans | 5 | 5 | LC160 |

| Aluminum block | 4 | 1 | LC245 |

| salt | 1.5 | 5 | LC219 |

| catalyst | 4 | 10 | LC315 |

Dahan Machinery has 12 years of experience in the production of vertical screw conveyors. The specifications of this product are (with shaft, without shaft), and the material of the shell blade: carbon steel, stainless steel. According to the particle size, conveying volume and conveying distance of the conveyed material, reasonable selection and design can be made to achieve no jamming, no arching, smooth discharge, complete models, stock supply, free selection and drawing design, and 12 months Quality warranty and lifetime maintenance services, products have been exported to the United States, Russia, Sri Lanka, Indonesia, Malaysia, the Philippines and other countries and regions.

The manufacturer selects and designs according to the parameters you provide. We have 15 years of experience in design and production, and the product quality is good.

1. If you are replacing, you need to provide flange (round or square), flange (outer diameter, inner diameter, flange hole center distance), inlet and outlet distance, if it is a new installation, you can ignore these parameters, when you install Just do it to our size.

2. It is necessary to provide some parameters such as installation conditions, material name, material particle size, whether the material has hardness, whether the material has viscosity, material temperature, import and export distance, and the conveying volume you need. you need.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.