For separation and sizing of powders, granules, suspensions

![]()

![]()

Price:$20.00-$3,680.00/Set/Set

Consult now and enjoy a 10% discount

International standard: ISO3310-1:1990 R20/3, R20, R40/3 series

Sieve diameter: 75mm, 100mm, 200mm, 300mm, 400mm, 500mm

Measuring range: 20µm-125mm

Feeding amount: 200g

Screen frame layers: 1-8 layers

Amplitude: 1-4mm Voltage: 220V

Power: 0.125KW Noise: ≤50dB

Dimensions: 360*300*736 Weight: 36 kg

Commitment:

Sieve shaker also called sieve shaker machine, ideal for dry and wet sieving, measuring quantitative particle size distribution of solids and suspensions, separating and classifying samples up to 2 kg in the measuring range of 20 µm - 63 mm, The advantages of sieve shaker machine include consistency, accuracy, and repeatable separations compared to manual sieve shaking methods for particle sizing. Lastly, shakers save a considerable amount of testing time.

Sieve shakers are available in different materials: brass, stainless steel or brass frame with stainless steel mesh. Diameters include 75mm, 100mm, 200mm, 300mm, 400mm, with mesh sizes ranging from 4mm to 38 microns. When stacked on a vibrating sieve, the top test sieve has the largest sieve size and the bottom sieve size is the smallest, which can accurately separate a granular material into 2~7 particle segments at the same time.

Sieve shaker machine is widely used in medicine, metallurgy, abrasives, chemical industry, pharmacopoeia, geology and other scientific research and production, laboratories and quality inspection rooms to accurately screen the particle size structure, liquid solid content and debris amount of granular and powdery materials. It can quickly and effectively measure the size of solid particles from 125mm to 20μm. Special sieves with pore sizes smaller than 20 μm can be used, but it should be understood that the finer the sieve, the more likely certain types of particulate solids are to clog or clog the pore size. However, "micro" sieving down to 5 μm is possible using special techniques.

Electromagnetic Sieve Shaker

Dry or wet sieving or micro-precision sieving for quantitative particle size analysis of various solids and suspensions

Measuring range: 5μm-63mm

Suitable screen diameter: 200 mm / 300 mm

Rotap Sieve Shaker

Used in the production and classification of diamond micropowder and superhard materials industry

Measuring range: 20 µm - 40 mm

Suitable screen diameter: 200 mm / 300 mm/span>

Ultrasonic Test Sieve Shaker

Suitable for fine powder with high static electricity, strong adsorption force, high density and light specific gravity

Measuring range: 20μm

Suitable screen diameter: 100 mm / 200 mm / 300 mm

| Effective | ||||

| Shape | Size | diameter | Depth | |

| Biggest | Smallest | |||

| round | 75 | 75 | 65 | 25 |

| round | 200 | 200 | 175 | 25,50 |

| round | 300 | 300 | 285 | 75 |

| square | 300 | 300 | 75 | |

| No. | name | unit | parameter |

| 01 | frame | the number of layer | 1-8 |

| 02 | frame diameter | mm | &200 |

| 03 | sieve size | mm | 0.025-3 |

| 04 | noise | dB | less than 50 |

| 05 | amplitude | mm | 2-500 |

| 06 | vibration frequency | times/min | 1440 |

| 07 | outside dimension | LWH | 350*350*(300+n*5) |

| 08 | power supply | V;HZ | 200;50 |

| 09 | machine weight | kg | 2-500 |

| 10 | vibration motor | power | o.12kw |

Commonly used sieve frames for sieve shakers are in three specifications with diameters of 200mm, 300mm, 400mm, etc. The screens have mesh requirements GB6003.1-1997 wire woven mesh and mesh requirements GB6003.2-1997 perforated plate screen mesh , The sieve frame of the two structures can also be installed in the test sieve or the flapping standard inspection sieve to classify the composition of various powder materials in each country.

Sieve shaker is a vibration motor as vibration source, vibration motor drive the vibration sieve machine base, through the base to mounted on the base of standard sieve test, standard test on the screen, to make them less than the test sieve sieve escapes hole material particles test sieve sieve into the lower level, so the screening, each layer test only stay in the same particle size of materials. To achieve the separation of different particle size and determine the particle size of the material composition. The purpose of screening, grading and filtering the materials in the test screen effectively.

Wet and dry fine sieving

Quantitative particle size distribution measurement of solids and suspensions with mesh diameters from 100 mm to 450 mm and mesh widths from 5 µm – 125 mm.

3-D Throwing Sports

The 3-D throwing motion ensures optimum utilization of the open sieve area and uniform movement of the sample across the entire sieve surface, with sample weights between 0.05 g and 15 kg.

Fast, Repeatable Results

Driven by a built-in 99-minute digital timer with an accuracy of 0.1 second, the screening time can be freely controlled to ensure the repeatability and consistency of the test, and the test data is more reliable.

Multilevel test

According to the detection requirements, a multi-layer screen frame can be added to accurately separate the granular material into 2-7 particle segments at a time.

SUS304 stainless steel

The screen frame is made of SUS304 (0Cr18ni9) stainless steel stretched and polished, with a wall thickness of 0.6 mm. The overall shape is strong and durable, without magnetism. The screen is fixed by soldering and will not relax.

Precise mesh

The sieve is woven by stainless steel, the hole diameter complies with the GB6003.1-1997 standard, and it is shipped out after passing the strict inspection, which can ensure the consistency and interchangeability of the same type of sieve in different batches.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 | 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 | 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

Mesh number is the number of mesh in a mesh of one inch (25.4mm) width. The larger the mesh number, the smaller the mesh.

Sieve: The sieve is the more technical part of the sieve shaker machine. The most commonly used mesh type is stainless steel woven wire mesh. Opening sizes from 5 inches (125 mm) to 635 mesh (20 microns).

Screen Frame: The frame is the circular metal ring used to hold the mesh in place. Standard frame sizes in the US are 3", 8", and 12". Internationally, 100mm, 200mm and 300mm are standard sizes. Screen frames can be made of stainless steel or brass.

Skirt: The main purpose of the skirt is to allow the sieves to stack without tipping over.

| Metal woven mesh | Metal perforated plate mesh | Electroforming mesh | Nylon mesh | Brass mesh | |

|

|

|

|

|

|

| Diameter | 200mm、75mm、300mm | 200mm、300mm | 75mm、200mm | 100mm、200mm、300mm | 75mm、100mm、200mm |

| Mesh size | 0.02mm~2.36mm | 1mm~125mm | 5um~500um | 6-500 mesh | 10-350 mesh |

| Features | Lowest cost, good flexibility, but lowest relative accuracy (large mesh allowed) | The mesh precision is uniform and not easily deformed, mainly used for the detection of large particles | Manufactured by electrochemical methods, the precision is the highest, and the theoretical precision can reach one micron | It is made of polypropylene PP material through special processing technology, which can meet the user's screening work for acid, alkali and corrosive materials. | It has corresponding corrosion resistance, the heat treatment temperature is between 650-850°C, and the annealing temperature is between 600-700°C. |

Sieve shaker is a machine device used to separate solid materials or mixtures of different particle sizes. The function of the screening machine is mainly reflected in the following three aspects:

Particle classification: Sieve shaker can classify raw materials according to particle size, so that materials of different particle sizes can be effectively separated.

Product screening: Sieve shaker can screen out particles that meet the requirements to ensure that product quality and specifications meet standards.

Improve production efficiency: Sieve shaker can quickly and accurately separate particles, improve production efficiency, reduce labor costs, and ensure the smooth operation of the production line.

| Cassia | 14 mesh | Buckwheat | 12 mesh | Tenebrio molitor eggs | 12 mesh |

| Worm dung | 30 mesh | Soybeans | 4-5 mesh | green beans | 10 mesh |

| Rice | 12-14 mesh | rice flour | 30-40 mesh | Cornmeal | 30-40 mesh |

| flour | 50-60 mesh | Miscellaneous grains | 40-50 mesh | Sesame Millet | 22-24 mesh |

| Fried Chicken Burger Breaded | 20-30 mesh | Mung bean flour | 40-50 mesh | Sesame powder | 40-50 mesh |

| Notoginseng powder | 100-120 mesh | Pine pollen | 100-120 mesh | Chinese medicine powder | 40-50 mesh |

| Oral Chinese medicine powder | 60-80 mesh | Traditional Chinese Medicine Mask | 80-120 mesh | Pearl powder | 120-150 mesh |

| Medicine residue | 60-150 mesh | Soy milk | 80-120 mesh | honey | 80-120 mesh |

| Soup dregs | 120-150 mesh | Tea water | 120-150 mesh | Cooking oil | 150-200 mesh |

User Ordering Information

The following is a detailed analysis of the basic working steps and precautions of the sieve shaker machine by Dahan Machinery:

Before the sieve shaker starts working, the following work steps should be done:

1. Check whether the connected power supply meets the requirements (corresponding to the nameplate inspection, and there is a grounding wire);

2. The inspection sieve must be placed horizontally;

3. The vibrating part of the sieve shake cannot be in contact with other objects;

4. Ensure that the bolts of each part of the inspection sieve body are locked;

5. Select the appropriate standard screen frame according to the characteristics of the target screening material;

6. Stack the screen frame on the screen frame base in order of aperture from small to large and from bottom to top;

7. Put the test material into the uppermost screen frame and cover it;

8. Adjust the height of the adjusting rod according to the total height of the screen frame, use the pressure plate and lock nut to position and compress the standard screen frame, and pay attention to the force on both sides;

9. According to the nature and feeding amount of the target material, set the running time on the timer, turn on the power, and start the inspection sieve to work.

10. Unscrew the lock nut, remove the pressure plate, and carefully remove the standard screen frame;

11. Cut off the power supply of the standard inspection sieve.

At this point, the basic working steps of the sieve shaker machine are completed. The operation of the standard inspection sieve is relatively simple, but the above steps should also be carefully compared and completed one by one to avoid errors caused by improper operation.

Xinxiang Dahan Sieve shaker machine manufacturer has ISO9001 international quality system certification, as well as EU CE dual certification. Dahan manufacturers will have a quality inspection department to verify the production of the screening machine. If the quality is unqualified, it will be returned to the factory for redo. The mesh size is as large as 13mm and as small as 0.03mm, which can meet the needs of most users.

1、Factory Show

Dahan is a direct-selling manufacturer, with sufficient product models, standard parts in stock, and special customization within 7 working days. The delivery is fast and the cycle is guaranteed.

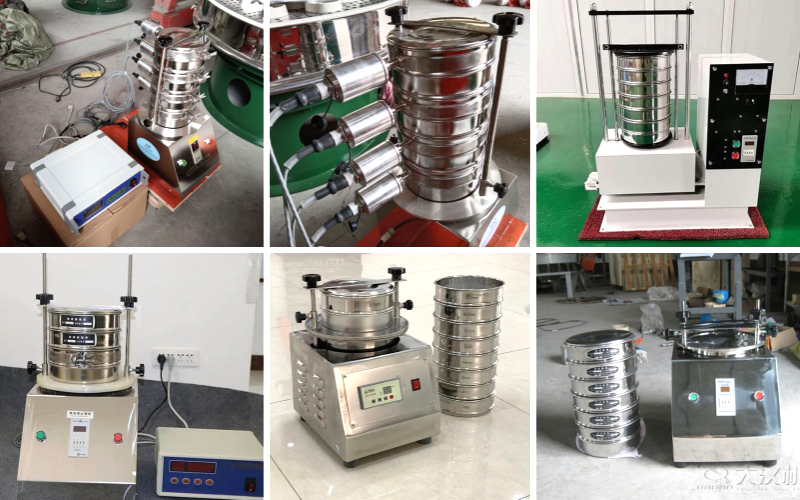

2、Finished Product Display

30 days of quality problems are guaranteed, and the warranty period of the whole machine is 1 year. If there is a quality problem during this period, our factory will replace it for free.

3、Qualification Honor

Since its establishment in 2008, it has been highly recognized by customers by virtue of high-quality products, professional technology, and high-quality services to meet customer needs. Accurate measurement of particle size structure, liquid-like solid content and sundries of granular and powdery materials in scientific research and production, laboratories, quality inspection rooms, and laboratories of colleges and universities in medicine, powder, building materials, national defense, geology and other departments Sieve, filter, test. It is also often used by Coca-Cola (China) Beverage Co., Ltd., Tsinghua University, North China University of Water Resources and Electric Power, Hainan Institute of Tropical Oceanography, Shanghai University, Lanzhou University and other units.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.