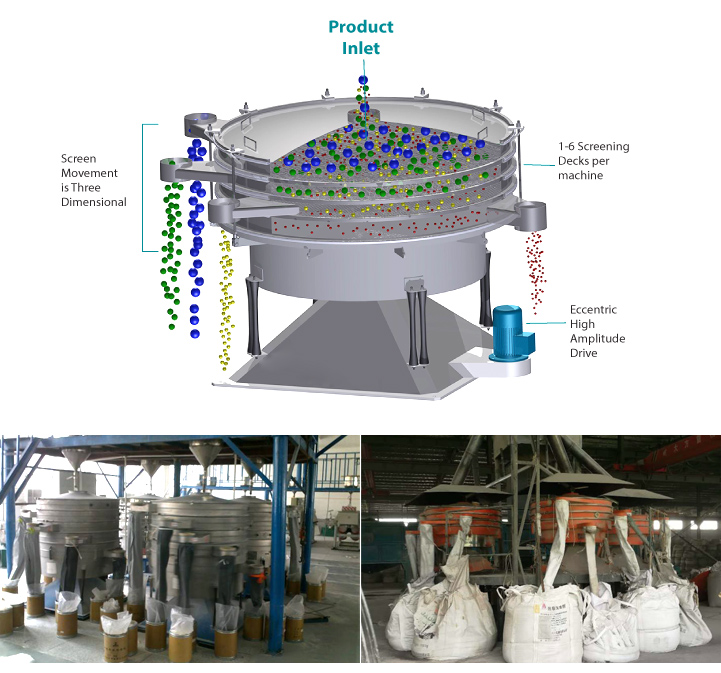

The Circular tumbler screen simulates the principle of artificial motion, and has plane circular motion and upward parabolic motion at the same time. The material presents an involute spiral motion on the screen surface, and the material is in precise contact with the screen mesh. Up to 6 particle sizes can be classified at the same time, achieving 99 % separation accuracy. The output of the circular swing screen is 3-5 times that of the ordinary screen machine, and the service life of the screen is also 5-10 times that of the conventional screening equipment. yield material.

The motion of the Circular strong>tumbler screen is similar to simple manual sieving, combining sieving (circular motion) with wind separation (parabolic motion), it can be used for separation and dust removal of powdery and granular products, and the sieving accuracy can reach 95 % or more, the processing capacity is 3-5 times that of ordinary screening machines, especially suitable for high feed rate (10kg/h-40t/h) and multi-layer separation (1-6 grades) of fine, light and difficult-to-screen products.

The Circular tumbler screen is similar to manual screening. After the power is turned on, the screen body starts, and the screen box moves approximately in a circular motion under the drive of the vibrating device. At this time, the screen box drives the entire screen surface to perform periodic motion, and the materials on the screen surface follow The screen box makes a directional jumping motion on the screen. During this process, the material smaller than the screen aperture falls to the lower layer of the screen and is discharged from the lower discharge port, and the material larger than the screen aperture is discharged from the upper discharge port. The layer is discharged from the outlet to complete the entire screening work.

1. Imitation of manual screening, the material is displaced on the screen, the net time is usually more than 85%, and the screening efficiency can reach more than 95%.

2. The diameter of the screen is 600mm-2900mm, the processing area is 0.28-6.4 square meters, the material passing rate can reach 99%, and the output can reach 40 tons/hour, which is 5-10 times that of ordinary vibrating screens.

3. The anti-blocking design is adopted under each layer of screen mesh, which can avoid the blockage of screen holes for products with high viscosity or static electricity.

4. The movement mode is a slight elliptical rocking movement, there is no high vibration, and the shape of the screening product will not be damaged.

5. Automatic airtight and vacuum design, good dustproof effect.

| Model |

Diameter (mm) |

Screen area (m²) |

Feeding size (mm) |

Screening size (mm) |

Capacity (t/h) |

Amplitude ((mm) |

Power (kW) |

| YBS800 | 800 | 0.29 | ≤25 | 0.073-3 | 6-10 | 5-8 | 0.75 |

| YBS1000 | 1000 | 0.71 | 8-15 | 1.5 | |||

| YBS1200 | 1200 | 1.11 | 15-30 | 2.2 | |||

| YBS1600 | 1600 | 1.83 | 25-40 | 3 | |||

| YBS2000 | 2000 | 2.62 | 30-50 | 4 | |||

| YBS2500 | 2500 | 4.61 | 40-60 | 5.5 |

Circular tumbler screen is mainly composed of feed inlet, upper cover, observation hole, screen frame, sealing ring, outlet, mesh frame, beam ring, main pivot assembly, adjustment block, spring, main shaft assembly, pulley, base, Inspection hole, motor and other parts.

In the production process of some industries, due to the different properties of materials, the required screening equipment is also different. For example, the shape of the material is irregular, strip, cylindrical, etc. There are three types of cleaning devices for the Circular tumbler screen for different materials. Cleaning device:

1. Bouncing Ball Cleaning: Special long-lasting, food-safe rubber balls bounce back to the bottom of the screen from the perforated plate below and remove clogged particles. It is easy to handle and maintain and can be used with most granular products.

2. Ultrasonic cleaning: The ultrasonic generator generates high-frequency vibration, which is transmitted to the screen through the transducer. This cleans the screen and can increase the capacity by quite a factor of 10, depending on the product, e.g. sieving of metal powder, rubber powder.

3. Brush cleaning: This method is particularly gentle, and the action of the conical roller brush under the sieve is especially suitable for round, crystalline and fragile materials. The brushes are driven by reduction gears mounted on the axle of the chassis.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.