centrifugal sifter

centrifugal sifter stainless steel centrifugal sifter

stainless steel centrifugal sifter twin centrifugal sifter

twin centrifugal sifter mobile centrifugal sifter

mobile centrifugal sifter centrifugal screen

centrifugal screen

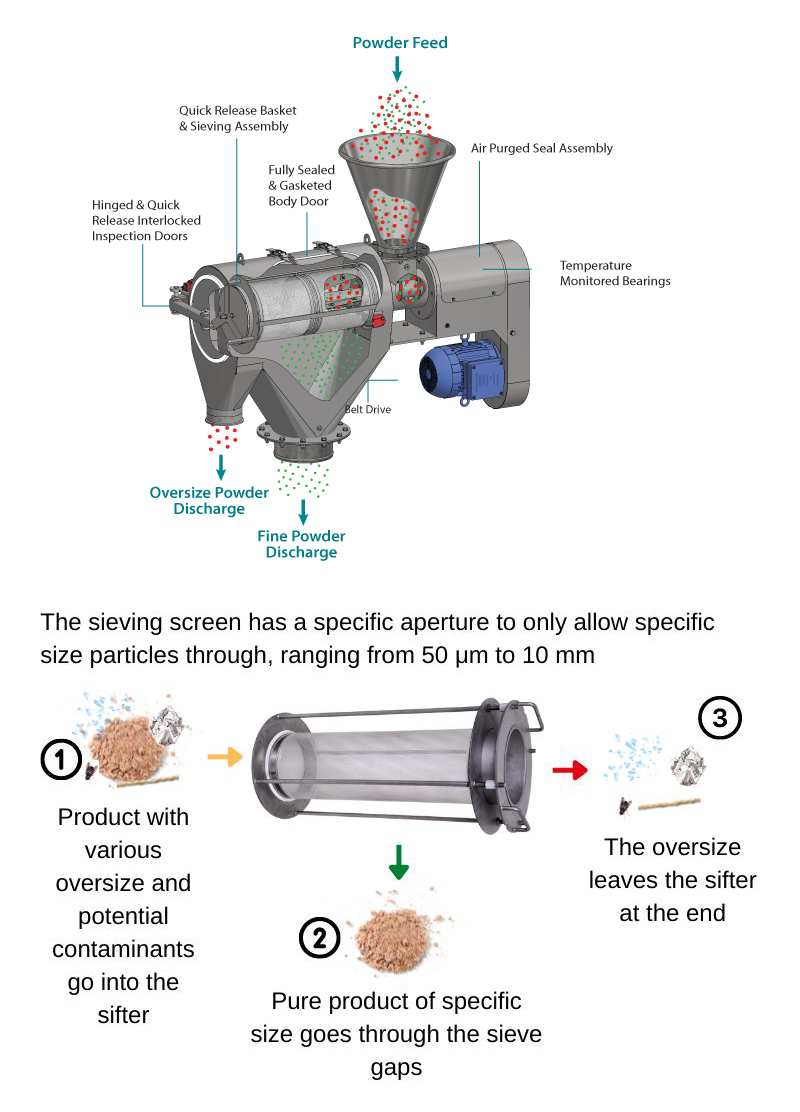

Use the strong centrifugal force generated by high-speed rotation to separate materials that do not meet the required size

![]()

![]()

Price:$900.00-$5,700.00/Set

Consult now and enjoy a 10% discount

Function: Remove unwanted particles from powder and break up clumps

Screen mesh: 80-530 mesh

Screen cylinder perforation size: 0.15-10mm

Processing capacity: 1-15 t/h

Material: carbon steel or stainless steel

Power: 2.2-5.5KW

Application: Ultra-fine powder with many fibers, high viscosity, light specific gravity and static electricity, such as heavy calcium powder, flour, hawthorn powder, traditional Chinese medicine powder, graphite powder, rubber powder, etc.

Commitment:

Centrifugal sifter is capable of screening, stripping and deagglomerating bulk solid materials at high throughput rates with little to no noise, vibration or product degradation. The large-sized particles enter the discharge chute through the sieve holes, and the undersized products enter the discharge port through the cylinder in a spiral shape. The paddles rotate at a speed of 600-800RPM, which can break up the agglomerates, and the screening efficiency can reach 85. -95%, the residue on the screen is basically 0 (difficult to achieve with ordinary vibrating screens), and the output is 5-10 times that of ordinary vibrating screens.

Centrifugal sifter machines are available in a range of sizes, the machine size is defined by the dimensions of the sieve surface; our sieve has a sieve area measuring 180mm x650mm long, rising to our largest machine 50-130with a sieve area of 500mm x 1300 long.All variants are available in carbon steel, 304 stainless, or 316 stainless steel with a number of surface finish options to suit your particular application.

Centrifugal sifter is very suitable for removing large particles and eliminating foreign matter from raw materials. It is less noisy and vibrating than other types of sieves. It usually has the following uses:

1. Safe screening or removal of impurities: Remove foreign matter and debris before the product enters the production process, or ensure product quality before filling.

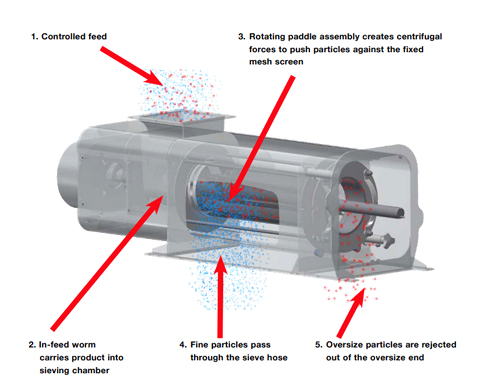

2. Deagglomeration: The main screening mechanism is rotary paddles that spin to create a centrifugal force that throws powder against the surrounding screen basket. Typically, the paddles spin at a rate of 600 – 800 RPM, providing a strong impact and dispersion effect when the material passes through, which helps to break up the agglomerated material.

Compared with ordinary sieves, centrifugal sifter is more suitable for screening some light, static, easy to adsorb, and easy to agglomerate fine powders.

3.Particle separation: To separate products with a varying particle size into two fractions, typically within the range of 40 µm to 5 mm.

A centrifugal sifter is a type of industrial equipment used for separating and classifying particles based on their size. There are several types of centrifugal sifters, including:

Horizontal Centrifugal Sifters

Also known as rotary sifters, these sifters have a cylindrical screen that rotates horizontally. The material is fed into the center of the screen, and the centrifugal force generated by the rotation causes the particles to move outward and separate based on their size.It is required that the fine material in the sieved raw materials should be 90% or more, which is suitable for fine powder sieving.

Vertical Centrifugal Sifters

These sifters have a vertically oriented screen that rotates around a central axis. The material is fed into the top of the sifter, and the centrifugal force separates the particles as they move down the screen.The wind generated by it will be stronger than the horizontal sieve, which is more suitable for large-capacity industrial sieving, used for sieving materials with more coarse powder.

How to choose: Whether to choose a vertical or horizontal centrifugal sifter depends on the actual application. The vertical centrifugal sifter has dense impeller blades and high wind speed, and its output is larger than that of the horizontal centrifugal sifter. It is generally used in the mining industry to screen powder (heavy calcium powder, etc.), requiring more than 90% of the fine materials in the screened raw materials, but its discharge is inconvenient, and a cyclone dust collector and a bag dust collector need to be used in combination.

The horizontal centrifugal sifter has 3-4 impeller blades and low wind speed. It is generally suitable for screening coarse powder materials, such as starch, milk powder, rice flour, corn flour, bran powder, rice husk powder, coated sand, lime powder and other materials. The bottom discharge is very convenient and widely used.

When material is fed into the input port of the powder screen, a micro-auger pushes the bulk powder into the cylindrical screening chamber, where the powder tumbles inside the screen basket due to the fast-spinning paddles connected to the central drive shaft. A cage supports the screen, which can be removed for screen maintenance and replacement. As the paddles rotate, powder particles are thrown toward the screen. Particles smaller than the mesh aperture pass through the screen and are conveyed to downstream processes through the discharge hopper. Oversized particles travel along the length of the screen until they exit through the overweight or waste outlet.

Centrifugal Force: The material to be screened is placed in a rotating chamber. This rotation creates centrifugal force, forcing particles to hit the screen.

Particle separation: particles smaller than the screen opening will pass through, while larger particles are retained on the screen surface.

Compared to traditional gravity screening: Centrifugal force increases separation speed and efficiency to more accurately separate particles while minimizing contamination. Centrifugal force also helps prevent mesh clogging, a common problem with other screening methods

Handling powders, agglomerates and granules

Centrifugal force is used to separate particles of two different sizes. The centrifugal force generated by the paddle is also very suitable for breaking up agglomerates and agglomerated powders, and sieving to 530 mesh.

High productivity

The screening penetration rate can reach 85-95%, and the residue on the screen is 0 (which is difficult to achieve with ordinary vibrating screens). The screen area is 3.5 square feet and 6 square feet respectively, and the processing capacity is 5-10 times that of the vibrating screen.

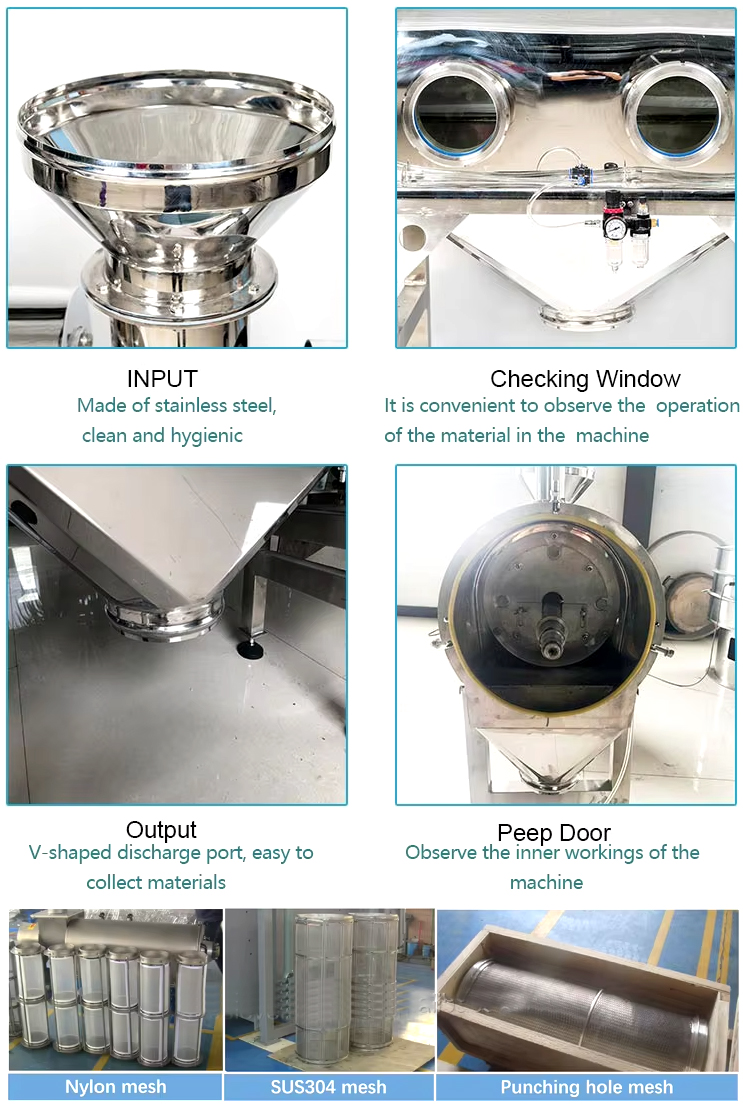

Clean and hygienic

The fully enclosed construction eliminates dust problems, prevents dust leaks and protects operator safety.

No vibration and low noise level

Centrifugal sifter is very quiet and works without vibration, the sieve is very quiet, the noise level is below 80DB to be precise.

Quick screen change

The internal parts of the screen can be quickly disassembled without the use of tools, the screen change in 30 seconds, inspection and cleaning through the easy-to-remove screen.

Easy to clean

The internal parts of the sieve can be quickly disassembled without the use of tools, which allows for easy and fast cleaning.

centrifugal sifter for flour

centrifugal sifter for silicon powder

| Model | A | B | C | D | E | F | G | H | I | J |

| WQS18-65 | 1430 | 460 | 420 | 1005 | 135 | 230 | 250 | 330 | 340 | 210 |

| WQS30-100 | 1845 | 655 | 766 | 1240 | 320 | 285 | 300 | 350 | 380 | 290 |

| WQS50-130 | 2230 | 870 | 790 | 1775 | 280 | 515 | 150 | 660 | 400 | 485 |

| Model | Material | Power | Application |

| WQS18-65 | Q235A | 2.2KW | Screening below 500 mesh |

| SUW304 | |||

| WQS30-100 | Q235A | 4KW | |

| SUW304 | |||

| WQS50-130 | Q235A | 5.5KW | |

| SUW304 |

WLQ-18-85, mesh diameter 180mm, length 850mm

WLQ-30-85, mesh diameter 300mm, length 850mm

| Comparison Items | Centrifugal Sifter | Vibrating Sifter |

|

|

|

| Working principle | Centrifugal force | Vibration |

| Applicable | Fine-grained, sticky, wet materials | Dry material |

| Accuracy | 500 mesh or even higher | 500 mesh |

| Capacity | One centrifugal sifter can replace the output of three circular vibrating sifters. | 100-5000 kg/h |

| Dust-free and noise-free operation | Completely enclosed and dust-free and noise level below 80DB | 70-100 dB |

How to choose: Whether to choose a centrifugal sifter or a vibrating sifter depends mainly on the characteristics of the material, the screening accuracy requirements, the processing volume, and the cost. If the material is highly viscous, high in humidity, and small in particle size, and the screening accuracy requirements are high, then a centrifugal sifter is more appropriate. If the material is dry, has a large particle size, and the screening accuracy requirements are not high, then a vibrating sifter is more appropriate.

Centrifugal sifters can be customized to meet specific industrial applications. Some common customization types include:

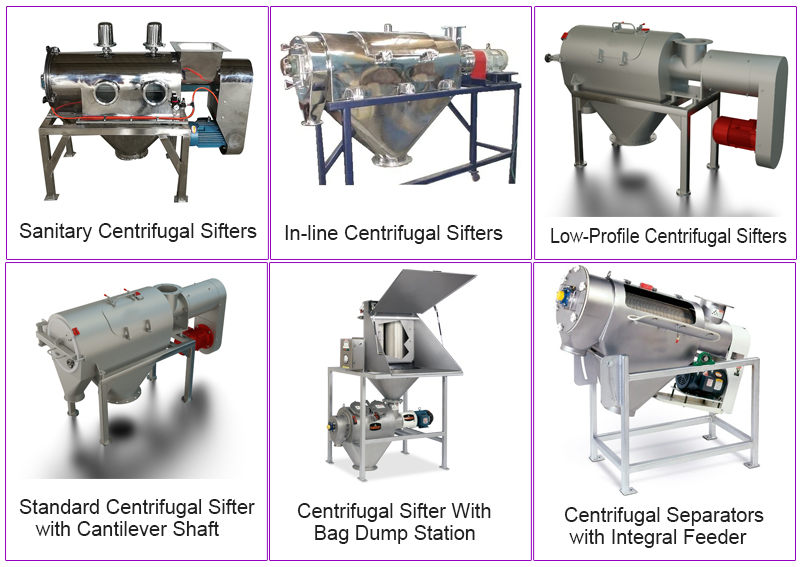

1. Sanitary Centrifugal Sifters: They are typically made of SUS304 or 316Lstainless steel to meet specific requirements for cleanliness and hygiene in food, pharmaceutical and other hygienic applications. Sanitary features may include smooth, easy-to-clean surfaces, quick-release clamps for easy removal and cleaning.

2. In-line Centrifugal Sifters: These sifters are designed to be installed in a pipeline and are used to remove oversized or undersized particles from the product stream. The material flows through the sifter, and the centrifugal force separates the particles based on their size.

3. Low-Profile Centrifugal Sifters: These sifters are designed to fit in tight spaces and have a low profile. They are often used in applications where space is limited.

4. Standard Centrifugal Sifter with Cantilever Shaft: has a cantilever shaft with two externally mounted bearings between the screening chamber and the motor drive (no bearings on the hinged end plate), allowing all components to slide freely from the shaft end for cleaning, screen replacement or check.

5. Centrifugal Sifter With Bag Dump Station: With integrated bag dump station and dust collector, it can remove bag fragments and other oversized pollutants from manually dumped bulk materials, while protecting operators and factory environment from dust pollution.

6. Centrifugal sifter screener with Integral Feeder: The integrated feeder eliminates the need for a separate feeder while reducing headspace requirements. The feed controller also prevents overloads caused by fluctuations, thus extending the life of the screen.

Centrifugal sifter is mainly composed of vibration motor, machine base, screen, feeding and discharging propulsion device, etc.

Motor: The motor drives and rotates at approximately 500RPM, providing vibration-free performance and high throughput with little or no product degradation.

Screens: A variety of pore sizes are available to meet a variety of screening applications throughout the processing and packaging industry.

Hinged access doors on the side of the housing allow for visual inspection, and the shaft end housing with vents and external bearings can be removed with screw knobs for replacement, inspection or cleaning of screens and paddles.

Feeding and discharging propulsion device: The rotating paddle throws the material towards and through the hole of the screen cylinder, and sprays the oversized particles to the discharge port through the downstream end of the screen cylinder.

Dahan Machinery provides a variety of anti-blinding devices to increase production by discharging close-sized particles from the screen holes. These devices reduce the gap between the rotating paddle and the cylindrical screen without contacting or wearing the screen. Reducing the gap between the rotating element and the screen surface increases the screening rate at close-to-size conditions, thereby increasing throughput.

1. De-Blinding With Rubber: Rubber wiper blades handle fibrous materials that would otherwise get tangled in the bristles or around jagged edges. The rubber blade allows oversized particles to pass through the rotating blade and is also effective in liquid/solid separation.

2. De-Blinding With Air: The all-in-one air brush keeps the screen clean while handling fine meshes that are susceptible to damage or wear by mechanical anti-blinding devices. Air enters from the end of the hollow drive shaft and exits through multiple air nozzles, blowing the screen clean.

3. De-Blinding With Brush: The brush is flexible and held approximately 1/16" to 1/8" (1.6mm to 3.2mm) from the screen surface to prevent damage while allowing the desired particles to pass easily through the screen holes.

| Material | Screen (mesh) | Capacity(kg/h) | Model | |

|

Light calcium powder | 120-180 | 600 | WQS18-65 |

|

Heavy calcium powder | 400 | 800 | WQS18-65 |

|

starch | 300 | 500 | WQS18-65 |

|

Zinc powder | 325 | 900 | WQS18-65 |

|

Fly ash | 120-200 | 364 | WQS18-65 |

|

Medicine powder | 120-160 | 1000 | WQS30-100 |

|

Quartz powder | 180-270 | 1280 | WQS30-100 |

|

Wood flour | 100-300 | 2000 | WQS50-130 |

|

Mica powder | 300-400 | 1500 | WQS50-130 |

Xinxiang Dahan Vibration Machinery Co., Ltd. is committed to solving all screening problems of powder and granular materials. Centrifugal sifter has airflow feeding function, feeder crushing agglomerate function and airflow coarse sieving function. The power consumption is reduced, the quality of the finished powder passing through the screen is better, and it can be customized according to your screening requirements.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.