Used in the laboratory to analyze the particle size structure of granular and powdery materials

ISO 9001:2015 Certified

Price:$23.00-$850.00/Set

Consult now and enjoy a 10% discount

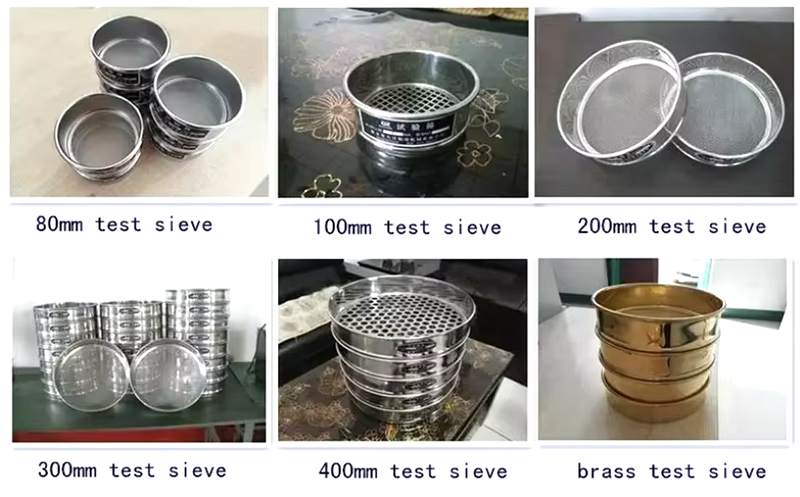

Frame diameter:500/400/300/200/120/80/75mm, or others as your requirements.

Surface type: Woven Wire Mesh/Perforated Plate/Electroforming Mesh

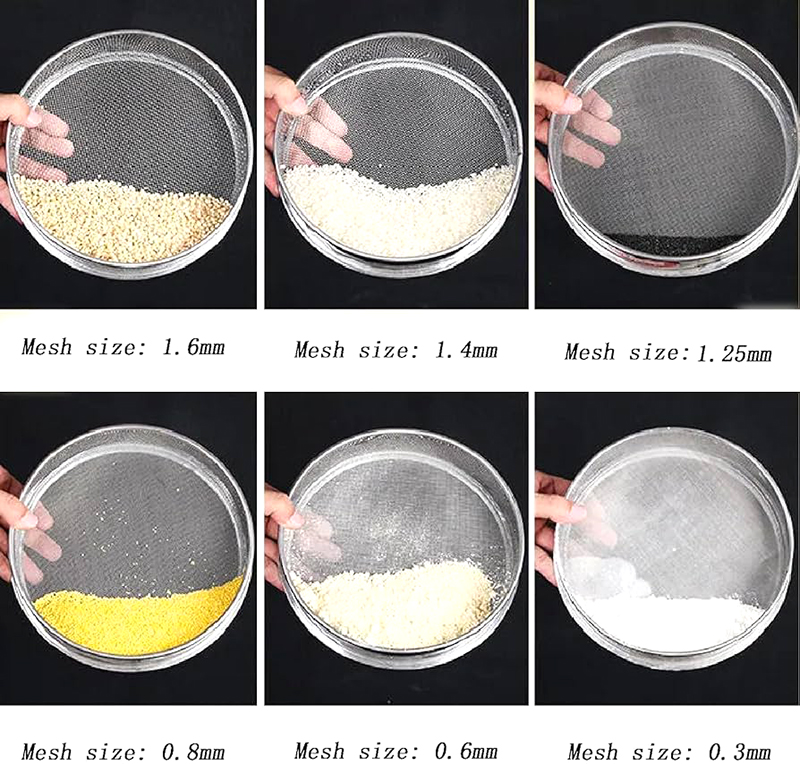

Aperture sizes: 0.02-2.36mm

Hole shape: Square/Round

Material:Stainless steel304/Brass/Chromeplate

Commitment:

Test sieve is also called laboratory test sieve.is a common tool used in various industries and laboratories to separate particles based on their sizes. These sieves consist of a metal frame with a woven wire mesh that allows particles smaller than the mesh size to pass through while retaining larger particles.

Test sieve is a common tool in laboratories and industries. It is used to screen granular materials and analyze particle size distribution. It can quickly and effectively measure the size of solid particles from 125 mm to 20 microns. It is usually available in 100mm, 200mm, 300mm and other models. It can also be customized into 75mm and 400mm according to customer requirements. Stainless steel, nylon and brass are also available.

There are two types of sieves: dry test sieves and wet wash test sieves.

Dry Test Sieves: For dry samples, the dry sample is poured onto a stack of sieves with decreasing sieve hole sizes. The sieves are then shaken or vibrated to separate particles based on particle size. Can be time consuming for large samples and may not be suitable for sticky or cohesive materials.

Wet Wash Test Sieves: For wet samples or sticky materials, it is effective in separating sticky or cohesive materials and may provide more accurate results for fine particles. The wet sample is poured onto a stack of sieves with decreasing sieve hole sizes. Water or a suitable liquid is then sprayed or poured onto the sieves to help separate the particles. The sieves are then washed and rinsed to remove any residue.

1. Diameter of the test sieve

The diameter of the test sieve generally has the following common specifications:

200mm: This is the most commonly used diameter in the laboratory and is suitable for most samples.

300mm: Suitable for large particle samples or when a larger screening area is required.

Other specifications: 100mm, 400mm, etc., select according to needs.

2. Material of the test sieve

The materials of the test sieve are mainly the following:

Stainless steel: The most commonly used material, with the advantages of corrosion resistance, high temperature resistance, high strength, etc., suitable for most samples.

Brass: Suitable for non-corrosive samples, the price is relatively low.

Nylon: Suitable for soft samples to avoid scratches on the samples.

Other materials: ceramics, rubber, etc., selected according to the characteristics of the sample.

3. Mesh shape of the test sieve

Circular mesh: It is the most common shape, with precise aperture size and high screening efficiency. It is suitable for screening most granular materials, such as soil, sand, gravel, powder, etc. The screen with a circular mesh is not easy to clog during the screening process and can effectively separate particles of different particle sizes.

Square mesh: It has high rigidity and is not easy to deform. It is suitable for screening irregularly shaped particles. It is suitable for screening fibrous, flaky or flat materials, such as minerals, fibers, films, etc. The square mesh screen can better control the passing direction of particles during the screening process.

You can also choose the machine according to your requirements, refer to this parameter: Note: The voltage and power in the table can be customized according to your requirements to suit your machine's working environment.

| NO. | Name | Unit | Parameter |

| 1 | frame diameter | mm | φ200 |

| 2 | the number of layer | s | 1~8 |

| 3 | sieve size | mm | 0.025-3 |

| 4 | vibrating amplitube | mm | 1~4 |

| 5 | vibration frequency | n/min | 1440 |

| 6 | power supply | V;HZ;KW | 220;50;0.12 |

| 7 | outside dimension | LWH | 350*350*(300+n*56) |

| 8 | machine weight | kg | 36 |

| 9 | time alarm | s | 999 |

| 10 | noise | db | Less than 50 |

| Test sieve pictures |  |

|

|

| Woven mesh test sieve | Perforated plate test sieve | Electroforming test sieve | |

| Test sieve surface |  |

|

|

| diameter | 75mm/200mm/300mm | 200mm/300mm | 75mm |

| Mesh size | 2.36mm-0.038mm | ≥3mm | 500mm-5μm |

| Material | Stainless steel/brass/tin bronze | Red copper | Stainless steel |

| standard | SO3310-2:1990 R20/3、R20、R40/3 | SO3310-2:1990 R20/3、R20、R40/3 | SO3310-2:1990 R20/3、R20、R40/3 |

| Feature | Low cost, wide application range, light weight, durable | The most wear-resistant, suitable for materials with high density, large impact on the screen surface, and irregular shapes | The highest accuracy, used in high-precision laboratory scenarios |

Grain screening

Laboratory powder testing

< span>Stainless steel material

The test sieve frame, sieve cover, and sieve bottom are made of high-quality stainless steel, which will never rust, non-magnetic, and have precise coordination and will not leak materials or water.

High screening accuracy

The sieve mesh is the standard aperture, with high precision, and the sieving particle size can reach 0.025mm~3mm.

High temperature resistance

The screen and the screen frame are connected by welding, which can withstand a high temperature of 400°, and can be used for inorganic and organic solutions.

Good interchangeability

All standard screens have good interchangeability and consistency. The platform does not need to be fixed for operation. Multi-layer screens can be installed, up to 8 layers.

Mesh/Screen: The mesh is the most technical part of a test sieve. The most commonly used type of mesh is stainless steel woven wire mesh. This comes in opening sizes 4" (100mm) to 635 mesh (20um).

For more a more in-depth explanation, refer to our article: How to Pick the Right Woven Wire Mesh (Mesh Count, Wire Diameter, and Micron Rating).

Frame: The frame is the round metal circle that holds the mesh in place. The standard frame sizes in the U.S. are 3 inch, 8 inch, and 12 inch. Internationally, 100mm, 200mm, and 300mm are the standard sizes. Sieve frames can be made of stainless steel or brass.

Skirt: The main function of the skirt is to allow the sieves to be stacked without toppling over.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

Here are some common uses for test sieves:

Particle size analysis: Determining the distribution of particle sizes in a material (e.g., soil, sand, flour).

Filtering: Separating solids from liquids or gases (e.g., straining pasta, filtering coffee).

Grading: Sorting materials based on their size (e.g., separating gravel from sand).

Sampling: Collecting representative samples of a material (e.g., taking a sample of soil from a field).

If you want to test a sieve to determine the particle size distribution of sand, you would:

Prepare the sieve: Ensure it is clean and free of any debris.

Weigh the sample: Measure a specific amount of sand.

Place the sample: Pour the sand onto the sieve.

Shake the sieve: Gently shake the sieve to allow the smaller particles to pass through.

Weigh the retained material: Weigh the sand that remains on the sieve.

Calculate the particle size distribution: Based on the weight of the retained material and the sieve's mesh size, you can determine the percentage of particles that are larger or smaller than a certain size.

Please let me know if you have any other questions or would like to proceed with a specific test.

Xinxiang Dahan test sieves can be used in the scientific research and production, laboratories, quality inspection rooms and university laboratories of metallurgy, chemical industry, medicine, powder, building materials, national defense, geology and other departments for the screening, filtering and detection of the particle size structure, liquid solid content and impurity content of granular and powdery materials. It is also commonly used in the inspection of the particle size composition of ordinary abrasives and the production and grading of superhard materials.

Dahan test sieves manufacturer has a 24-hour service mechanism, no holiday service, free design, professional pre-sales, sales and after-sales team, providing free design consultation, free on-site guidance, one-on-one exclusive design plan from the designer in 2 hours, 30-day refund for quality problems, 1-year warranty for the whole machine, and lifetime maintenance.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.