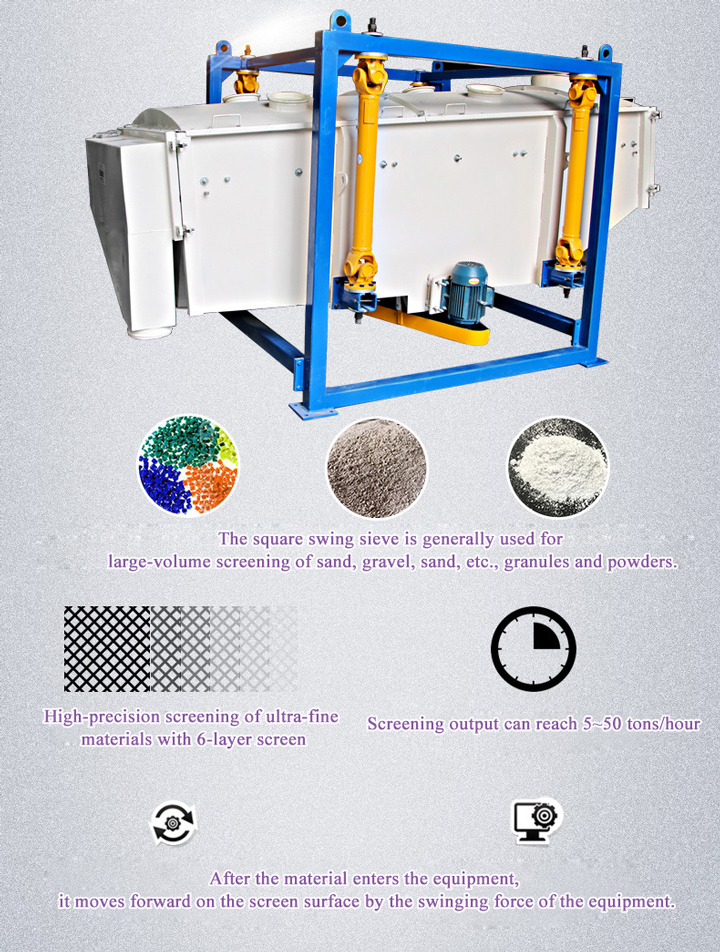

Reverse rotary screening method to quickly disperse materials

![]()

![]()

![]()

Price:$900.00-$8,500.00/Set

Consult now and enjoy a 10% discount

Screen specification: 2-200 mesh

Output: 9-60 tons/hour

Screen surface inclination: 5-8°

Power: 3-7.5KW

Number of layers: 1-5 layers

Application:

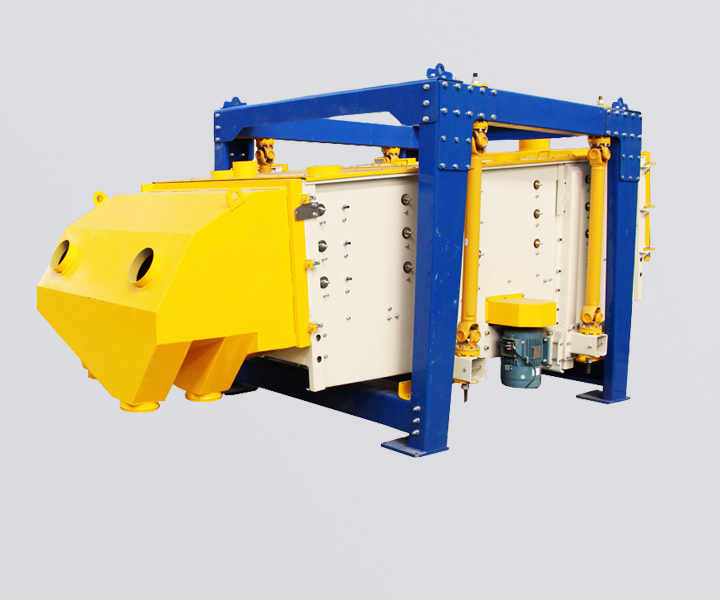

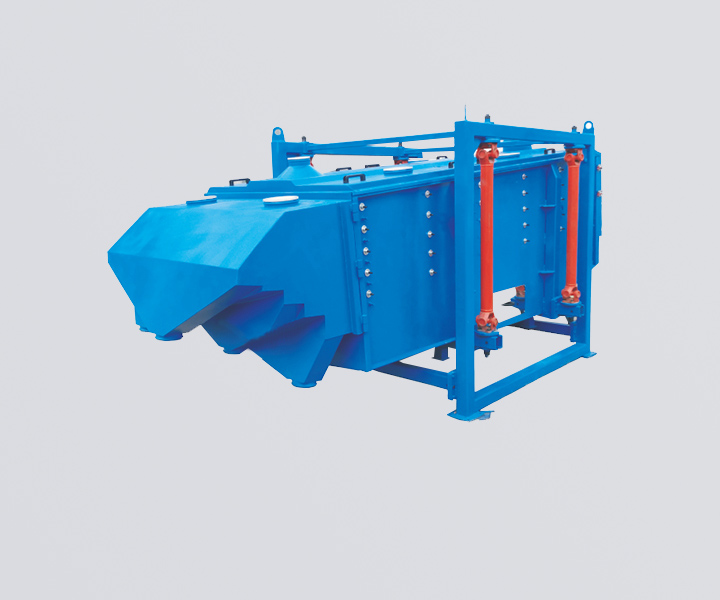

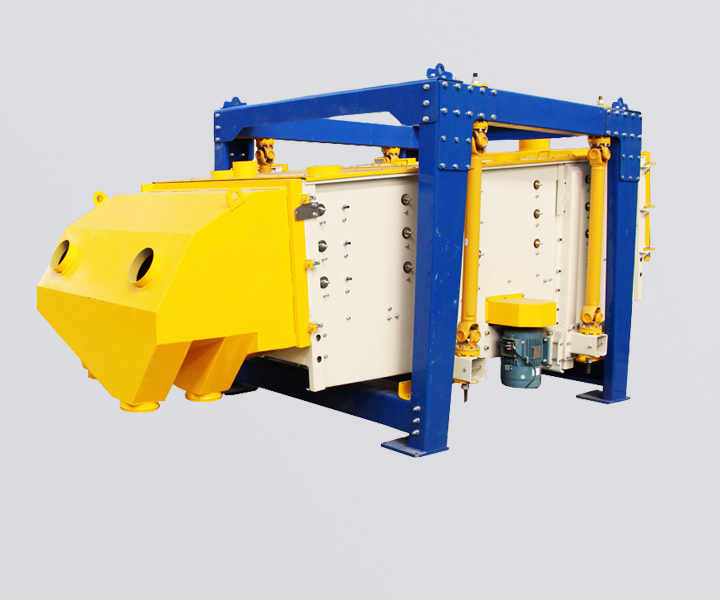

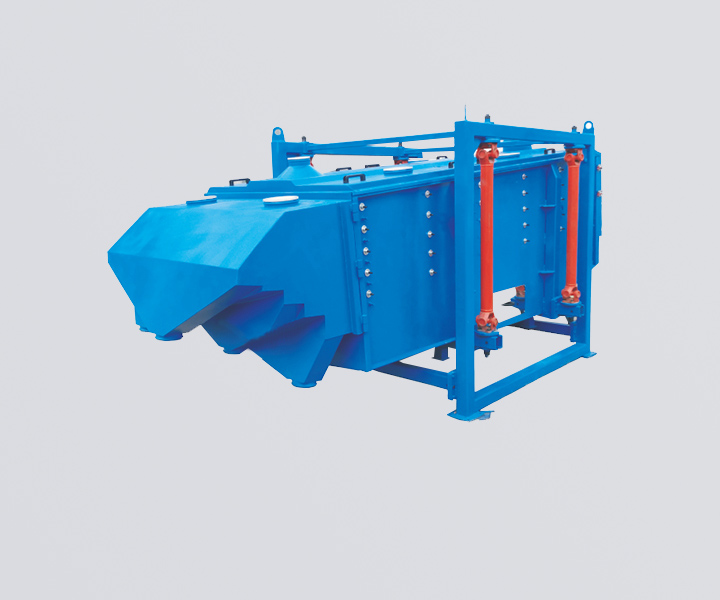

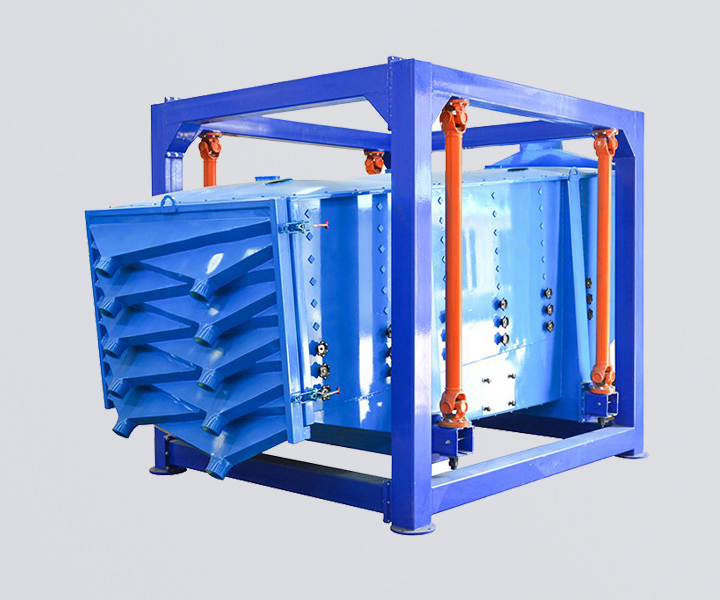

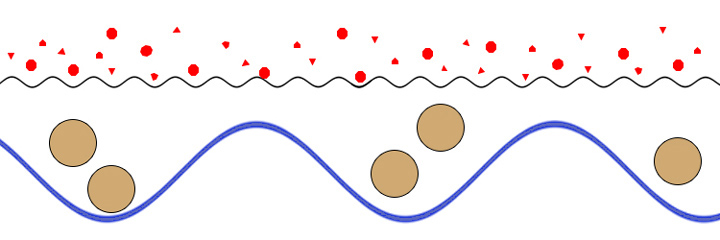

Square tumbler screen, also known as rectangular tumbler screen, reciprocating screen, adopts cyclic reciprocating motion to transmit a set of combined motion to the entire screen surface. Material screening starts at a horizontal circular motion feed end, and the circular rotation motion of the feed end is transmitted to the entire screen. The screen surface enables the material to be quickly distributed, which maximizes the utilization rate of the screen surface, with high screening efficiency and large processing capacity.

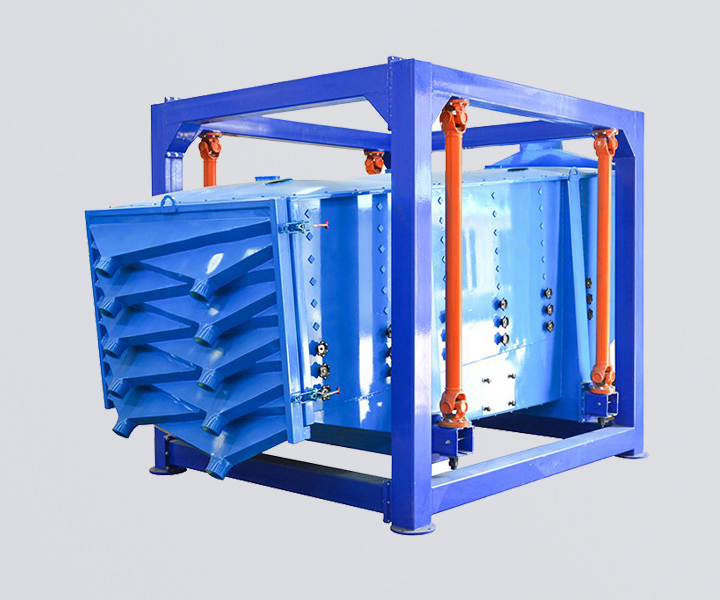

Square tumbler screen is mainly composed of feed port, upper cover, observation hole, screen frame, sealing ring, discharge port, net frame, beam ring, main pivot assembly, adjustment block, spring, main shaft assembly, pulley, base, It is composed of inspection holes, motors and other parts.

When the square tumbler screen is activated, the shaking body of the screen machine, namely the screen box, will reciprocate back and forth under the action of inertial force. The screen box drives the screen surface to periodically shake, so that the material on the screen surface will do a directional jump with the screen box. During the movement, the materials smaller than the sieve surface aperture fall to the lower layer through the sieve holes and become under the sieve. The materials larger than the sieve surface aperture are discharged from the discharge after continuous tumbling and jumping motion to complete the screening work.

| model | Effective screening area(m²) | power(KW) | Screen inclination(º) | Number of layers | Rotation frequency(r/min) | Screen box stroke(mm) |

| FYBS1030 | 3 | 3 | 5-8 | 1-5 | 180-260 | 25-60 |

| FYBS1036 | 3.6 | 3 | 5-8 | 1-5 | 180-260 | 25-60 |

| FYBS1230 | 3.6 | 4 | 5-8 | 1-5 | 180-260 | 25-60 |

| FYBS1236 | 4.32 | 4 | 5-8 | 1-5 | 180-260 | 25-60 |

| FYBS1530 | 4.5 | 5.5 | 5-8 | 1-5 | 180-260 | 25-60 |

| FYBS1536 | 5.4 | 5.5 | 5-8 | 1-5 | 180-260 | 25-60 |

| FYBS1830 | 5.4 | 7.5 | 5-8 | 1-5 | 180-260 | 25-60 |

| FYBS1836 | 6.48 | 7.5 | 5-8 | 1-5 | 180-260 | 25-60 |

| FYBS2030 | 6 | 7.5 | 5-8 | 1-5 | 180-260 | 25-60 |

Reciprocating motion

The reciprocating oscillating movement can quickly send the materials to the screen surface, small materials quickly pass through the mesh surface, and large particles are gradually transported to the discharge end.

No blockage

A bouncing ball cleaning device is installed under each layer of screen. The bouncing ball directly hits the screen to remove particles stuck to the screen, keeping the surface of the screen clean at all times.

Large output

Screening within 0.3mm-180 mesh, the inclination angle of the screen surface is 0°-5°. The output of a single machine can reach 60 tons/hour.

Multi-layer screening

1-5 layer multi-layer design (multiple can reach 10 layers), can obtain various specifications of finished products at one time.

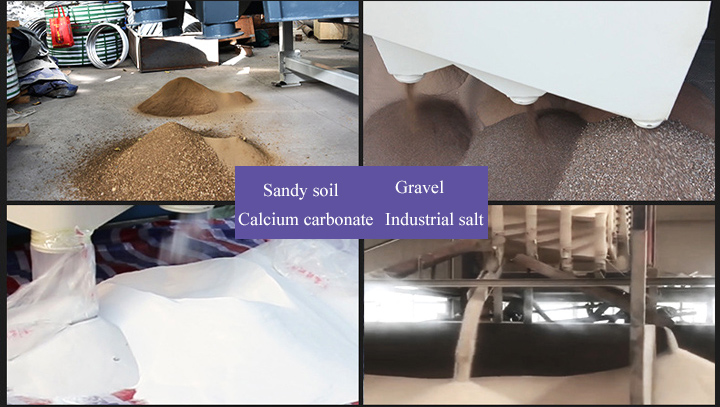

Square tumbler screen is widely used in chemical industry, medicine, food and spices, tea, feed, plastic, rubber, fertilizer, sugar and salt industry, wood industry and plywood, metallurgy, non-ferrous metals, non-ferrous metals, magnetic materials, recycling industries and other industries. Classification of fine materials and other operations.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.