Used for precision testing and sorting of materials in the laboratory

nternational standard: ISO3310-1:1990 R20/3, R20, R40/3 series

Price:$20.00-$3,680.00/Set/Set

Consult now and enjoy a 10% discount

Applications: Particle size distribution analysis, sample preparation, fractionation

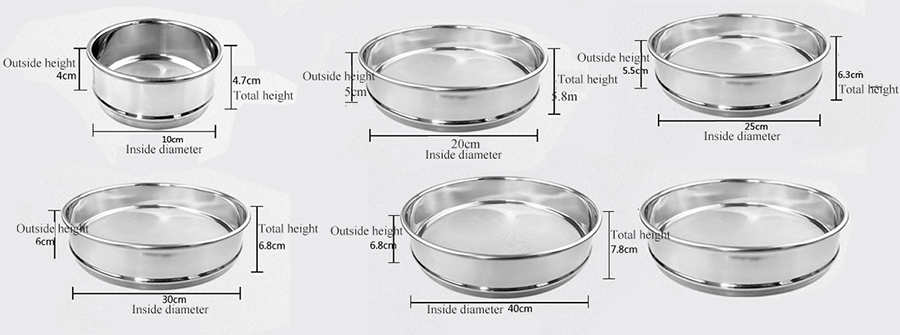

Screen diameter: 75mm, 100mm, 200mm, 300mm, 400mm

Screen depth: 32, 50 or 65 mm

Braided wire cloth: 30 µm to 11,2 mm (stainless steel)

Circular bore: 0.5 to 125 mm (stainless steel)

Square Bore: 4.0 to 125 mm (Stainless Steel)

Screening materials: powders, aggregates, suspensions, seeds, etc.

Industrial fields:

Laboratory test sieves , also called lab sieve, can be used in the laboratory for particle size determination, separation and classification of powders, bulk cargoes and suspensions. The laboratory test dieves can quickly and effectively measure the size of solid particles from 125 mm to 20 μm. Special sieves with a pore size of less than 20 μm can be used, but it should be understood that the finer the sieve, the easier it is for certain types of solid particles to block or block the pore size. However, special techniques can be used to perform "micro" sieving as small as 5 μm.

Laboratory Test Sieves are usually equipped with Φ100mm, Φ200mm standard sieve, standard sieve and Φ300mm standard sieve. We can also produce test sieves according to customer requirements.

Wire Braided Mesh Test Sieve

Frame diameter:ø 75 / 200 mm/ 300 mm

Surface type: wire gauze

Mesh sizes: 0.02 mm - 2.36mm

Standards: GB/T6003.1-1997 / ISO3310.1

Metal Perforated Plate Test Sieve

Frame diameter:ø 200 mm/ 300 mm

Surface type: perforated plate

Mesh sizes: 1 mm - 125 mm

Standards: GB/T6003.2-1997 / ISO3310.2

Electroforming Test Sieve

Frame diameter:ø 75 mm/ 200 mm

Surface type: electroforming

Mesh sizes: 5μm - 500μm

Standards: GB/T6003.3-1999 / ISO3310.3

Woven Wire Mesh Sieves: The materials are selected from high-quality stainless steel, brass, tin bronze, nickel, molybdenum, etc. Low cost and good toughness. The screens that meet the GB/T6003.1-1997 standard are selected among the screens. Generally, the diamond industry has the most applications.

| 3.35mm | 1.7mm | 600μm | 212μm |

| 2.36mm | 1.18mm | 425μm | 150μm |

| 2mm | 850μm | 300μm | 75μm |

Perforated Plate Sieves: The punching precision is uniform and it is not easy to deform. It is mainly used for the detection of large particles. There are two types of round holes and square holes. They are mostly used for round hole slag powder collection screens, round hole sandstone screens, etc.

| 75mm | 26.5mm | 13.2mm | 8mm |

| 53mm | 19mm | 11.2mm | 6.7mm |

| 37.5mm | 16mm | 9.5mm | 4.75mm |

The below table shows the detailed data of different models of laboratory test sieves use stainless steel 304 test sieves for your reference.

| Mesh shape | Diameter | Effective screen surface diameter | H | |

| Min | Max | |||

| round | 75mm | 75mm | 65mm | 25mm |

| 200mm | 200mm | 185mm | 25mm, 50mm | |

| 300mm | 300mm | 275mm | 75mm | |

| square | 300mm | 300mm | 75mm | |

If you have special requirements, please click on the contact us below to provide you with professional and customized services.Contact Us

| Serial Number | Name | Unit | Date | |

| 1 | Standard sieve body | layer | 8 | |

| 2 | Screen diameter | mm | φ200φ100φ75 | |

| 3 | Screening size | mm | 0.038-3 | |

| 4 | Noise | dB | ≤50 | |

| 5 | Feeding amount (one time) | g | ≤200 | |

| 6 | Amplitude | mm | ≤5 | |

| 7 | Motor | voltage | V | |

| Rotating speed | r/min | 1420 | ||

| Power | KW | 0.125 | ||

| 8 | Dimensions | mm | 360×300×736 | |

| 9 | Machine quality | kg | 25 | |

The mixture of particles of different sizes pass through the sieve or sieve mesh, the smaller particles pass through the sieve hole, and the larger particles are intercepted by the sieve mesh. It can only be passed if it is in a favorable position, if it is in other positions on the screen it will not be passed.

The sieving process can be divided into two stages: first, remove particles smaller than the standard pore size, and secondly, separate particles of a size close to the standard pore size. Through the opening. Ideally, each particle is presented separately to one opening, just like the larger opening, but for most particle sizes, this is not practical.

Featured materials

Made of SUS304 stainless steel, it is resistant to acid and alkali, high temperature, low temperature, not easy to rust, and can withstand high temperatures below 300 degrees.

Precise mesh

Sieve mesh sizes from 20 µm to 125 mm, which conforms to the international standard ISO3310-1: 1990 R20/3, R20, R40/3 series.

Standards compliant

The supporting sieve mesh implements the ASTM standard, and the aperture and wire diameter are all standard specifications to ensure the accuracy of the test and detection.

Laminate use

1-8 sieve frames can be added as required, and after the sieving is completed, the materials of multiple granularity segments required can be sieved at one time.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 70# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

Sieve Cover: Used to protect stored test sieves from dirt and dust.

Mesh/Screen: The sieve is the most technical part of the laboratory test sieves. The most commonly used mesh type is stainless steel woven wire mesh. Opening sizes are 4 inches (100 mm) to 635 mesh (20 microns).

Frame: Frames are circular metal rings that hold the grid in place. Standard frame sizes in the U.S. are 3 inches, 8 inches, and 12 inches. Internationally, 100mm, 200mm and 300mm are standard sizes. The screen frame can be made of stainless steel or brass.

Skirt: The main function of the skirt is to allow the sieves to be stacked without tipping over.

Laboratory test sieves are widely used in laboratories, quality inspection rooms and other inspection departments for particle and powder material particle size distribution determination, product impurity content, liquid solid content determination and analysis.

| Cassia | 14 Mesh | Buckwheat | 12 Mesh | Yellow mealworm eggs | 12 Mesh |

| Soybeans | 4-5 Mesh | green beans | 10 Mesh | Rice | 14 Mesh |

| Cornmeal | 40 Mesh | flour | 60 Mesh | Miscellaneous grains | 50 Mesh |

| Mung bean flour | 50 Mesh | Sesame powder | 50 Mesh | Pine pollen | 120 Mesh |

| Pearl powder | 150 Mesh | Medicine residue | 150 Mesh | Soy milk | 120 Mesh |

| Worm dung | 30 Mesh | rice flour | 40 Mesh | Medicine powder | 150 Mesh |

| Honey | 120 Mesh | Soup dregs | 150 Mesh | Cooking oil | 200 Mesh |

Laboratory test sieves are used to analyze a wide variety of materials, including powders, granules, and other solid materials. The specific material being analyzed will depend on the industry and application, but here are some common materials that are analyzed using laboratory test sieves:

1. Pharmaceuticals: Pharmaceutical powders and granules are commonly analyzed using laboratory test sieves to ensure that the final product is of a consistent size and quality.

2. Food and Beverage: Food and beverage powders, such as flour, sugar, and coffee, are often analyzed using laboratory test sieves to ensure that they are of a consistent size and quality.

3. Chemicals: Chemical powders and granules are commonly analyzed using laboratory test sieves to ensure that they meet specific size and quality specifications. This includes materials used in the production of plastics, paints, and other industrial materials.

4. Construction materials: Materials used in construction, such as sand, gravel, and concrete, are often analyzed using laboratory test sieves to ensure that they are of a consistent size and meet specific quality standards.

5. Ceramics: Ceramic powders and materials are commonly analyzed using laboratory test sieves to ensure that they are of a consistent size and quality, and to determine the particle size distribution of the material.

Laboratory test sieves can be used to measure particle size such as cement clinker, coffee, chemicals, fertilizers, abrasives, flour, grains, metal powders, minerals, nuts, plastics, sand, seeds, soil, etc.

Laboratory test sieves can quickly and efficiently measure solid particle sizes from 125 mm to 20 μm. Special sieves with pore sizes smaller than 20 μm can be used, but it should be understood that the finer the sieve, the more likely certain types of particulate solids will clog or clog the pore size. However, "micro" sieving down to 5 μm is possible using special techniques.

| Soil project | Standard | Test Sieve Requirements | Calibration result |

| moisture | Determination of soil dry matter and moisture | Aperture 2mm | 2.07mm |

| Gravimetric method HJ 613-2011 | |||

| organic carbon | Determination of Soil Organic Carbon | Aperture 2mm | 1.93mm |

| Potassium Dichromate Oxidation - Spectrophotometry | |||

| HJ 615-2011 | Aperture 2mm | 0.262mm | |

| total chromium | Determination of total chromium in soil | Aperture 0.149mm | 0.153mm |

| flame atomic absorption spectrophotometry | Aperture 0.149mm | ||

| organic carbon | Determination of Soil Organic Carbon | Aperture 2mm | 1.93mm |

| HJ491-2009 | |||

| copper | Determination of soil quality copper and zinc | Aperture 2mm | 2.07mm |

| flame atomic absorption spectrophotometry | |||

| zinc | GB/T17138-1997 | Aperture 0.149mm | 0.153mm |

| Determination of lead and cadmium in soil quality | |||

| graphite furnace atomic absorption spectrophotometry | |||

| lead | GB/T 17141-1997 Determination of lead and cadmium in soil quality | Aperture 2mm | 2.07mm |

| KI-MIBK Extraction | |||

| flame atomic absorption spectrophotometry | |||

| cadmium | GB/T17141-1997 | Aperture 0.149mm | 0.153mm |

There are several types of mechanical shakers and vibration devices that can be used with laboratory test sieves, and the choice of equipment will depend on the specific requirements of your application. Here are some common types of shakers and vibration devices used for particle size analysis:

1. Ordinary laboratory test sieves: Various experimental objects within 400 meshes are accurately screened. The standard vibrating sieves equipped with common soil sieves, gravel sieves and pharmacopoeia sieves are all standard test sieves.

2. Ultrasonic laboratory test sieves: It is a fine powder classification equipment developed on the basis of standard test sieves.

3. Rotap sieve shaker: Through the combination of the double drive of the ejector hammer and the vibration motor, the fine materials that are difficult to be screened by ordinary standard test sieves can be sieved with high precision. Granularity check. The disadvantage is that there will be a lot of noise during operation.

4. Magnetic levitation laboratory test sieves: It covers the screening equipment that integrates mechanical physical motion and high-frequency electromagnetic vibration. At the same time, it performs up and down vibration, front and rear reciprocating motion, and left and right rocking motion, so that the material produces a reciprocating rotational motion in the screen frame. Screening any material will not remain on the screen mesh, and it can be screened to 5 microns.

1. The equipment should be placed horizontally, confirm that the power supply meets the requirements of the nameplate, and ensure that it is grounded; note that the vibrating part cannot be in contact with other objects; check whether the bolts of each part are locked.

2. Determine the standard screen frame to be selected according to the inspected materials and corresponding standards.

3. Stack the standard sieve frames on the vibrating plate of the test sieve machine according to the aperture from small to large, from bottom to top.

4. Put the material to be inspected into the top standard screen frame, cover the top cover of the standard screen, adjust the height of the adjustment rod according to the total height of the standard screen frame, and then use the pressure plate and lock nut to position and tighten the standard screen frame ( Note: The force on both sides should be consistent).

5. Set the running time on the timer according to the nature of the material and the amount of feed, and then turn on the power switch, and the standard screen will start to work.

6. After the standard sieve stops working, unscrew the lock nut, remove the pressure plate, and carefully remove the laboratory test sieves frame.

7. Cut off the power supply.

Q: How do I choose the right mesh size for my sample?

A: 1. Determine the particle size range of your sample, 2. Consider the shape and density of the particles, 3. Consider the intended use of the final product, 4. Use a standard mesh size.

Q: What does the laboratory test sieve Φ200*50-0.075/0.05 mean?

A: Φ200*50, this is the diameter and height of the sieve. -0.075/0.05, this is the hole size of the sieve and the diameter of the wire, in mm. The hole of the wire mesh is a square hole, and the size means that the side length of the square hole is 0.075mm.

Q: What are some common sieve sizes used in the pharmaceutical industry?

A: 45 µm (commonly used sieve size), 90 µm (typically used for analyzing particle size distribution of powders used in tablet manufacturing), 125 µm (typically used for analyzing particle size distribution of powders used in capsule manufacturing), 250 µm (used for Analysis of particle size distribution of larger particles).

Q: How do laboratory test sieves differ from oth er types of sieves?

A: Laboratory test sieves are specifically designed for use in laboratory settings and are optimized for accurate and precise particle size analysis. They differ from other types of sieves in terms of their size, mesh size, construction material, tensioning mechanism, and use with mechanical shakers.

Q: How long is your delivery time?

A: Generally, if there is stock, it will be 3-5 days, if there is no stock, it will be 7-10 days, depending on the quantity.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.