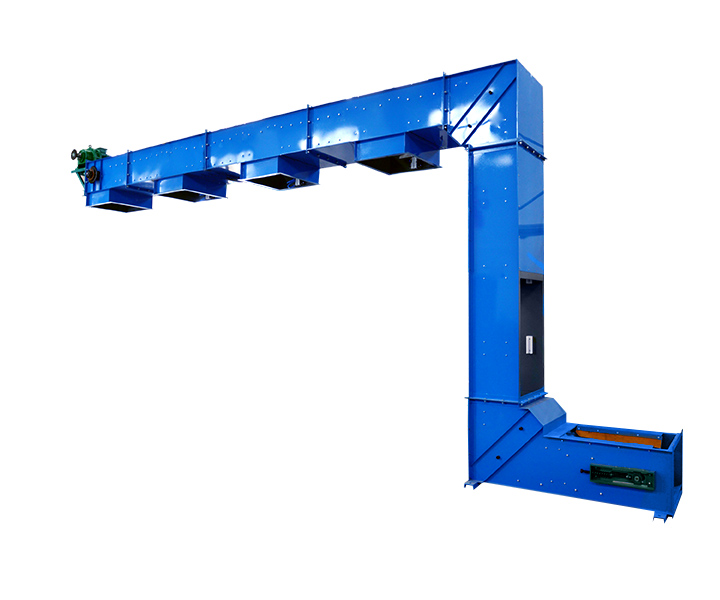

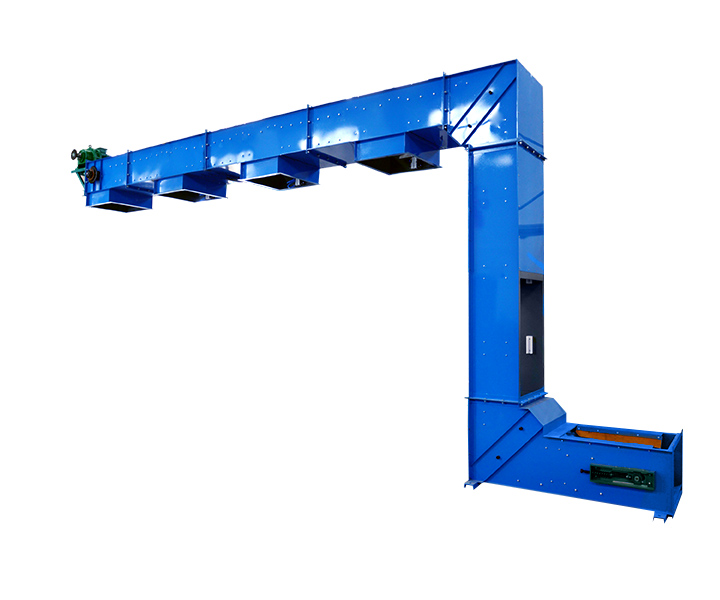

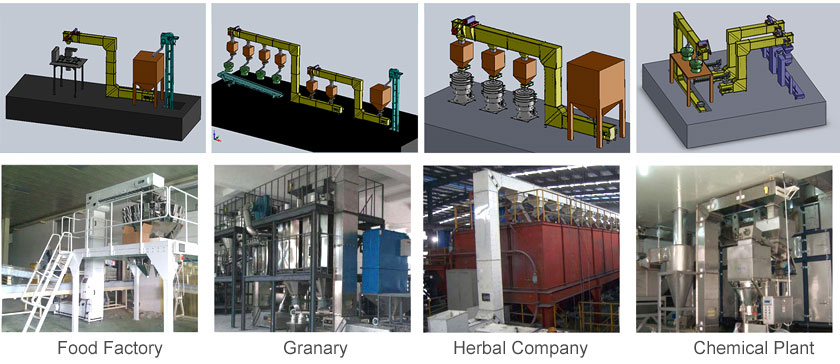

Z type bucket elevator

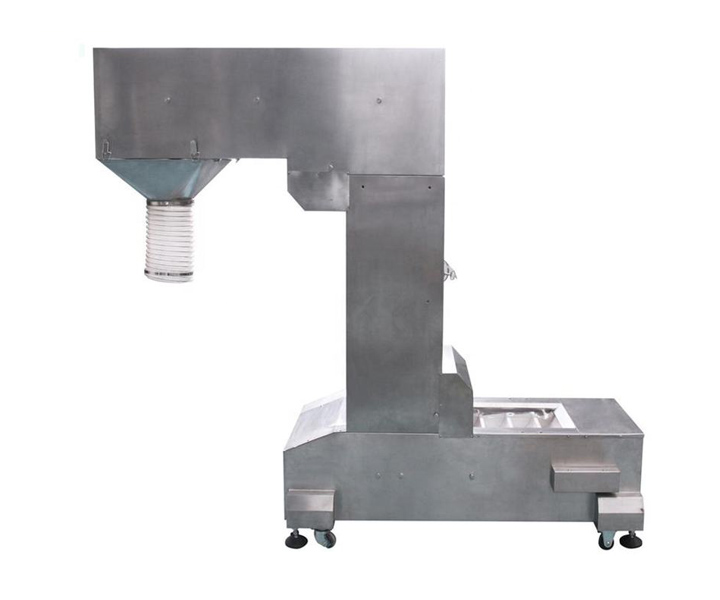

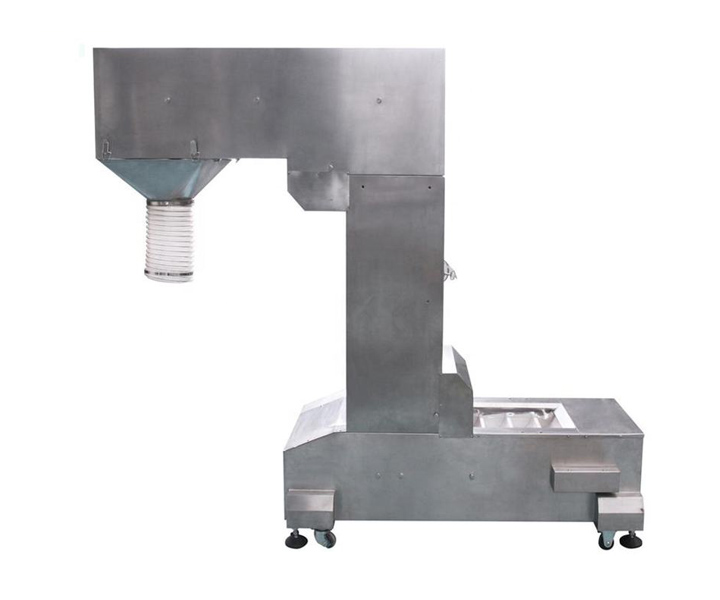

Z type bucket elevator Stainless steel z type bucket elevator

Stainless steel z type bucket elevator Z type bucket elevator with multi-point feeding

Z type bucket elevator with multi-point feeding Z type bucket elevator with multi-point discharge

Z type bucket elevator with multi-point discharge Z type bucket elevator system

Z type bucket elevator system

Ideal for lifting powders, bulk granules or fragile products from low level to combination scales or other equipment

![]()

![]()

Price:$1,000.00-$6,400.00/Set

Consult now and enjoy a 10% discount

Bucket Material: Food Grade PP

Conveying Speed: 2-5 m³/h

Bucket Volume: 1.8L, 4.0L, and 6.0L (Customizable)

Discharge Height: 2-12 m

In-Feed Length: 863 mm

Out-Feed Length: 1930 mm

conveying capacity: 3-10m³/h

Number of Outlet(s):Single or Muti-dicharge outlets

Application: It is used for conveying powdery, granular and small pieces of materials. At present, it is mostly used for the feeding of weighing packaging machines, the feeding and re-feeding of color sorters, and the three-dimensional cycle feeding and unloading of automatic production lines.

Commitment:

As the main part of the packaging line, the Z type bucket elevator is mainly used to transport the product from the low position to the required height and distance. The material is transported through the hopper suspended on the chain, which can be combined horizontally-vertically-horizontally, and can be single-pointed. Or multi-point feeding, single-point or multi-point unloading is completed through the unloading device, the bucket capacity is 1.8L, 4L, 6L, and the feeding height is about 500 mm. In addition, according to the requirements, the blanking height can be from 2 meters to 12 meters Rice varies.

The Z type bucket elevator can customize multiple feed ports according to the customer's production process requirements, and 2-7 discharge ports can be selected. Multiple entrances and multiple discharge points can be combined into a system to meet the supply needs of multiple warehouses and save money. Purchase cost of customer equipment.

Multi Discharge Z Type Bucket Elevator

2-7 discharge ports are available, multiple inlets and multiple discharge points can be combined into one system to combine or separate product streams as needed, which can meet the continuous feeding of multiple silos in a row.

Price:$1,300.00-$6,800.00/Set

The standard discharge height is 3296mm, ground length is 863mm, the upper part length is 1930mm and the productivity is 3-6.5m3/h.

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

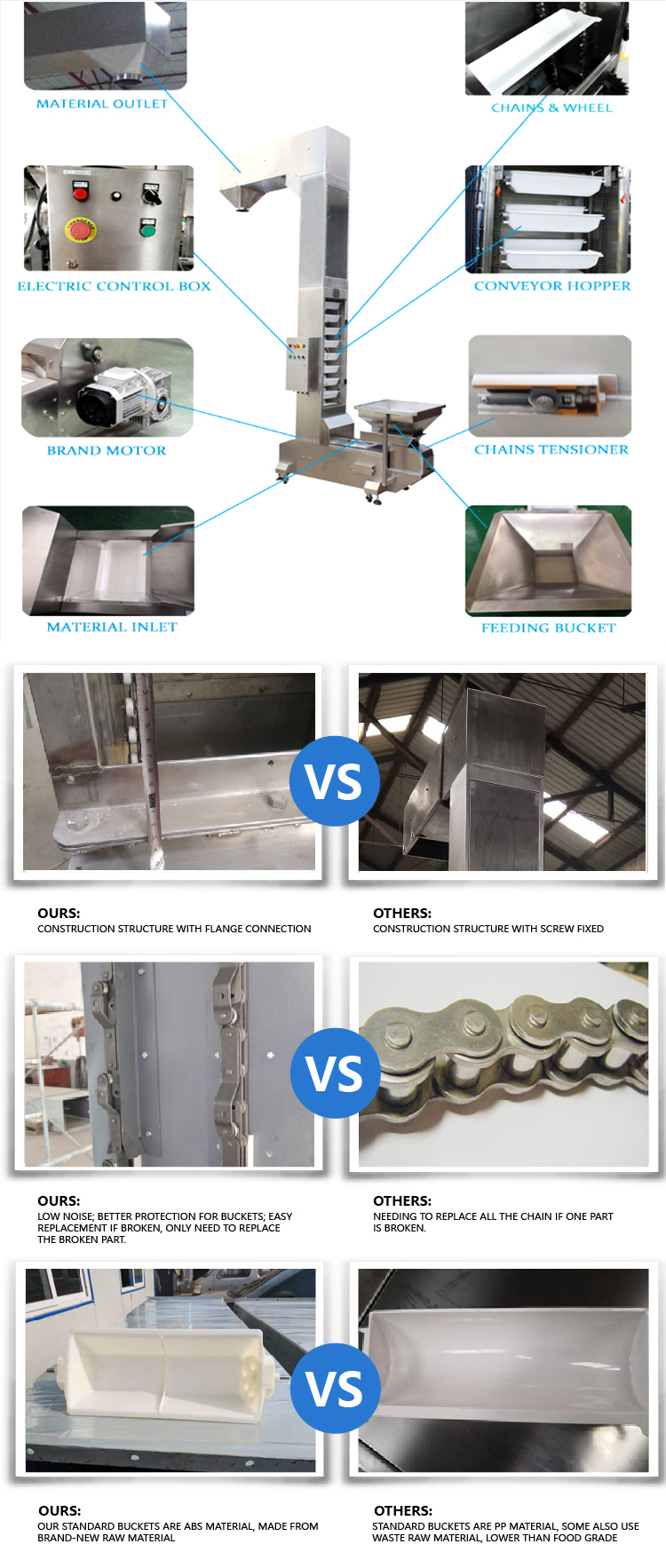

The top of the two endless chains is full of hoppers, and the hopper scoops up the material from the storage below. When the motor drives the chain to rotate, the material is lifted to the top with the conveyor chain, and the material is lifted and transported to the designated position for unloading. Its running trajectory is horizontal conveying first, then vertical lifting, and then horizontal conveying, similar to the letter Z.

Multipoint feeding and multipoint unloading

The Z type bucket elevator can customize multiple feeding ports or feeding ports according to the actual lifting needs to meet the needs of multiple silos or multiple feeding ports, and can easily connect with various types of feeding equipment.

High efficiency

It can be designed according to the customer's site. The horizontal length is 1.2 meters to 40 meters, and the vertical height is 1.5 meters to 50 meters. The double-machine parallel method can be used for those above 30 meters, which is suitable for the process needs of different industries.

Zero damage rate

Since the material slides into the hopper, it is not forced to scrape, so the material will not be broken.

Food grade requirements

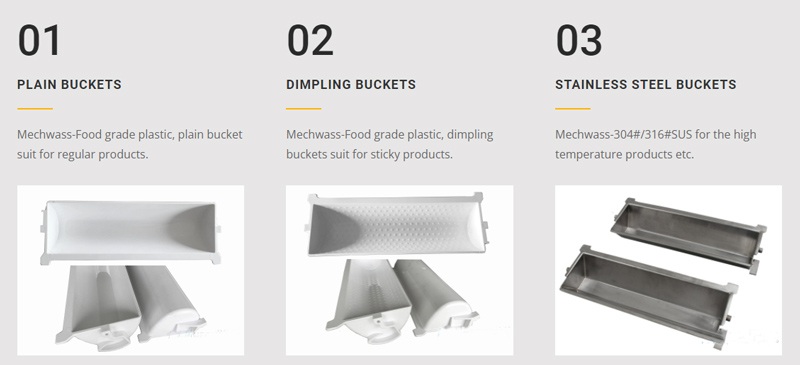

The hopper is made of food grade reinforced polypropylene and is one piece molded to withstand temperatures from -10 to 120 degrees Fahrenheit.

Sealing structure

The shell of the whole machine is closed, and the material leaks less during the operation of the machine, and at the same time, the flying of dust is reduced, which meets the requirements of environmental protection.

Small footprint

Because of its flexible and changeable composition, compact body and horizontal-vertical-horizontal conveying method, Z type elevator greatly reduces the situation that the equipment occupies a large area.

| Z Type Bucket Elevator | Other Bucket Elevators |

| Used in a variety of environments that require gentle handling. Z-type feeding, C-type feeding, Z-C mixed feeding and multi-point feeding, multi-point unloading and other occasions | It can continuously transport materials vertically upwards on a belt or chain. |

| Since the material is poured into the hopper, it is not forced to scrape, so the lifted product will not be damaged, and it is suitable for nuts, melon seeds, potato chips, feed and other materials. | With inflow feeding and induced discharge, it is easy to destroy the shape of the product, suitable for materials such as fertilizers, potash fertilizers and salt, cement, sand and gravel. |

| Multiple feed ports or discharge ports can be customized to meet the continuous feeding of multiple silos in a row, and can be easily connected with various feeding equipment. | One inlet, one outlet |

| The segmented horizontal length and lifting height can be combined, the horizontal length is 1.2 meters to 10 meters, and the vertical height is 1.5 meters to 12 meters. | The vertical height can reach 40 meters. |

The z type bucket elevator is mainly used to transport the product from the low position to the required height and distance. It can unload at multiple points and reduce the damage rate of the material. It is used in occasions such as multi-point loading and multi-point unloading. Material weighing and packaging machine, material color sorter and inspection and feeding, automatic production line loading and unloading cycle perspective, multi-point automatic weighing and batching system feeding.

Our products are currently running in the following automated production industries: pet food, puffed food industry, feed industry, candy industry, fresh and dried fruit industry, health food industry, food processing industry, finishing, chemical and pharmaceutical industry, metal industry, military industry, etc.

| Plaster | Wallboard Gypsum Conveying | Feed and Grain | Various applications |

| Leading | Lead recycling | Render | Widely used, rinse well |

| Food Handling | Various food grade applications | Glass Factory | Conveying and metering |

Z type bucket elevator for lifting peanuts

Z type bucket elevator for lifting sunflower seeds

Z-type bucket elevator manufacturers provide a lot of customized services for different customer production process requirements and material characteristics, such as material customization of box, hopper, chain and sprocket, and the lifting materials are, 201, carbon steel, 304, 316 and other materials.

The last and most important point, the number of discharge ports and feed ports can also be customized to meet the feeding needs of customers' multiple silos, 2-7 discharge ports are available, multiple inlets and multiple discharge points can be Combined into one system, combine or separate product streams as needed, with customizable discharge heights, infeed heights, lengths, and more.

Other types: C type, E type, F type, T type, etc.

| Details | 1. The buckets are made of a food grade reinforced polypropylene, molded in one piece and can handle temperatures from -10 to 120 degrees Fahrenheit. |

| 2.The bucket elevators allow for controlled feeds at one or more locations and can easily interface with various types of feeding devices | |

| 3.All parts have easy to remove inspection covers and a conveniently located inspection window. The buckets have a quick release mechanism to facilitate fast installation or removal of buckets. All elevators are equipped with an automatic chain tensioning device and built-in overload protection | |

| Options | Bucket Volume :1.8L,4L,6L |

| Machine Frame:304SS or Mildsteel Frame | |

| Stock Bin : 80L/120L | |

| Bucket material: SS304 stainless steel bucket/carbon steel bucket/food ABS or PP bucket | |

| Feeding method: common hopper feeding/electromagnetic vibrating feeder | |

| Voltage: 220V, 380V (single-phase or three-phase) |

Chassis: semi-closed chassis - dustproof chassis - stainless steel chassis - carbon steel spraying chassis.

Hopper: stainless steel hopper - carbon steel hopper - food plastic hopper.

Drive: explosion-proof reducer, ordinary reducer.

Sprocket: alloy steel chain - stainless steel chain.

Chain: alloy chain - stainless steel chain.

Control: manual start stop, automatic stop, variable speed control.

Others: Explosion-proof whole machine, electromagnetic vibrating feeder feeding device

1. Solve the problem of conveying and breaking peanuts, sesame seeds, pet food, nuts, etc.

During the processing of food materials, there are generally strict requirements for crushing. For example, peanut products are required to achieve zero crushing. Traditional conveyors are likely to cause peanut red coats to fall off, broken petals, etc. The use of bucket elevators can reduce material damage.

Powder puffed food is easy to produce broken powder during the conveying process, which in turn affects the product quality. The use of a bucket elevator can also reduce damage and protect the integrity of the material.

2. Solve the transportation problem of highly corrosive materials

Corrosive materials such as salt, edible alkali, chemicals, and pharmaceutical raw materials are prone to chemical reactions with system components, causing component corrosion. Conventional conveying equipment includes plastic buckets, rubber belts, polymer scrapers, etc. These materials are easily corroded by acid and alkali salts. If we choose the bucket, shell, chain and sprocket made of 316L stainless steel, the parts that the material may come into contact with are all 316L stainless steel or corrosion-resistant materials, so that the corrosion problem can be avoided.

3. Solve the problem of high abrasive material conveying

Due to the hard texture of some materials or the high hardness components such as carbon and silicon, the traditional conveying equipment wears a lot, and the spare parts of the conveying equipment need to be replaced frequently.

During the operation of the Z type bucket elevator, the material and the contacting parts are in a relatively static state, which can solve the wear problem caused by sliding friction.

4. Solve the transportation problems of large particles, irregular, block materials, high density and high dust materials

For the transportation of some large particles, irregular and block size materials, traditional conveyors are sometimes difficult to deal with, while the bucket of the Z type elevator is relatively adaptable, as long as the size of the bucket can accommodate materials can be transported.

In addition, some high-density materials and high-dust materials cannot be unloaded by centrifugal force, or centrifugal unloading will generate large dust. We can also transport them smoothly at low speed through bucket elevators.

5. Solve the problem of conveying high temperature materials

Many materials will generate high temperature during processing, such as high temperature peanuts, high temperature sesame, furnace ash, etc., the highest temperature can reach above 220 °C.

Through special temperature-resistant treatment of chains, sprockets, buckets, bearings, etc. in the equipment, almost all metal components can cope with high-temperature materials and achieve the purpose of conveying.

Xinxiang Dahan Vibration Machinery Co., Ltd. mainly produces: Z-type bucket elevator, multi-discharge z-type bucket elevator and other conveying equipment, wehave 1.8L, 4.0L, and 6.0L bucket, the product model is complete, can be customized according to users Requirements, materials to be transported, on-site conditions and cost budgets to provide selection customization.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.