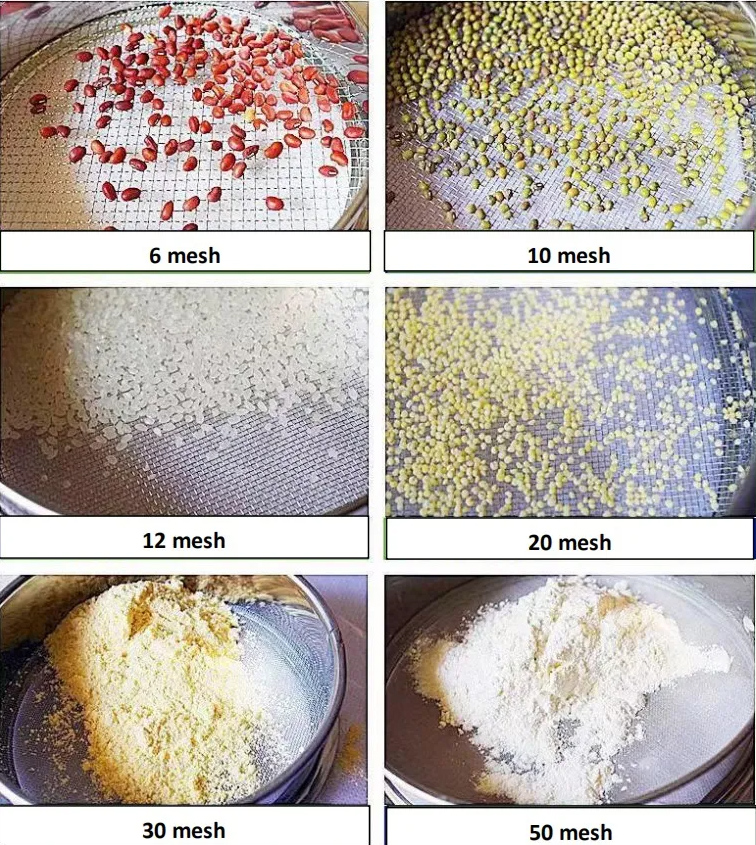

It can be used to screen, filter and detect the particle size structure, liquid solid content and debris content of granular and powdery materials.

![]()

![]()

Price:$23.00-$850.00/Set

Consult now and enjoy a 10% discount

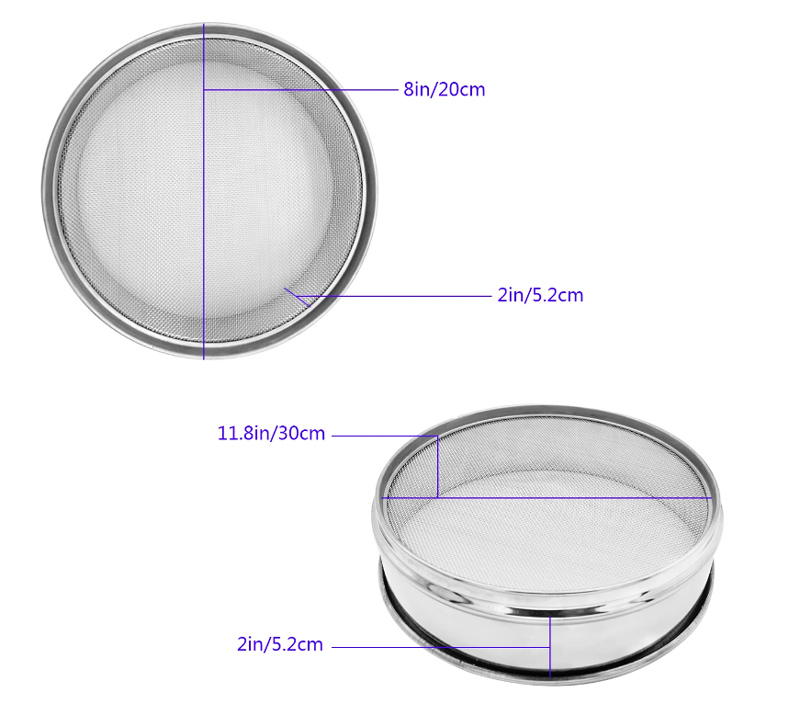

Diameter: 200mm

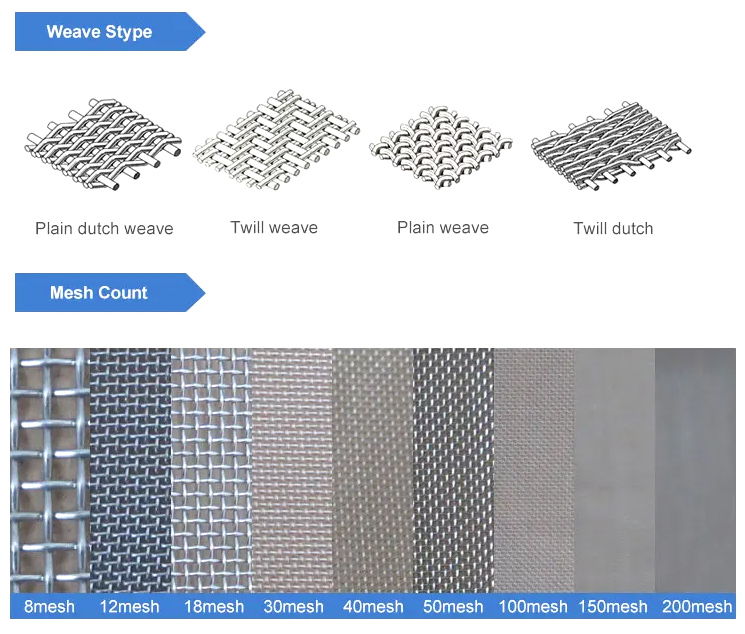

Surface type: Woven Wire Mesh/Perforated Plate/Electroforming Mesh

Aperture sizes: 0.02-2.36mm

Hole shape: Square/Round

Number of layers: 1-7 layers

Weight: 36kg

Material: Stainless steel304/Brass/Chromeplate

International standard: ISO3310-1:1990 R20/3, R20, R40/3 series

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Φ200 standard test sieve refers to a test sieve with a diameter of 200 millimeters (mm). Test sieves are commonly used in various industries to measure the particle size distribution of granular materials. They consist of a woven wire mesh with uniform openings that allow particles of specific sizes to pass through.

The Φ200 standard test sieve is often used in particle size analysis to determine the distribution of coarse particles. The number "200" indicates the mesh size of the sieve, which represents the number of openings per linear inch. In this case, the Φ200 sieve has approximately 200 openings per inch.

| roduct Name | Stainless Steel Wire Mesh Test Sieves |

| Material | stainless steel or copper |

| Wire Diameter | 0.025-2mm |

| Mesh Counts | 2-2800mesh |

| Weave Type | plain weave ,twill weave |

| Hole Shape of Bottom Screen | Square Hole -- Weave Mesh, Crimped Mesh, Perforated Mesh; Round Hole -- Perforated Mesh; Diamond Hole -- Expanded Mesh, Perforated Mesh |

| Size | 6 "8 ",10" .24", other size can be customized |

| Height | 2" .4" or customized |

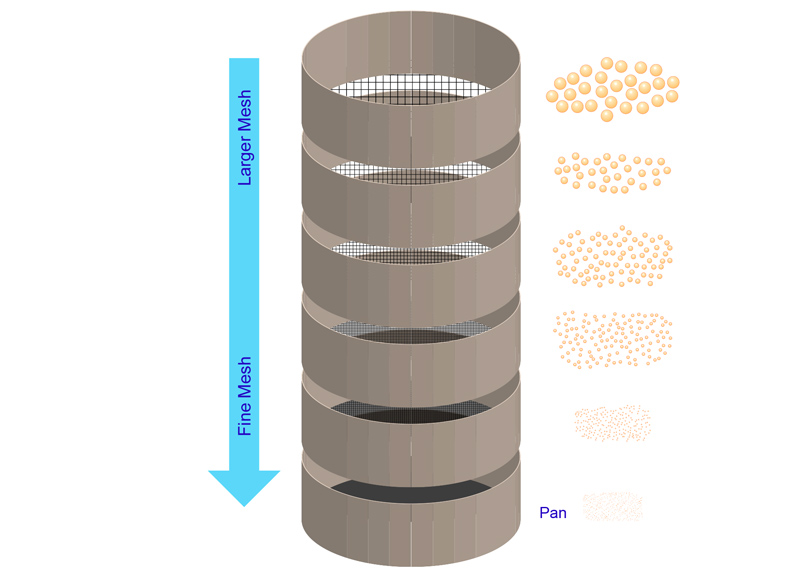

When conducting a particle size analysis, the material to be tested is placed on top of the Φ200 sieve, and mechanical or manual shaking is applied to facilitate the separation of particles based on their size. The particles retained on the Φ200 sieve are collected and weighed, providing information about the percentage of particles within that specific size range.

Precise particle size determination

Φ200 standard test sieve can accurately measure particle size within the specified range. The uniform mesh ensures consistent and reliable results, allowing accurate determination of particle size.

standardization

Comply with widely accepted international standards such as ISO, ASTM or other industry-specific standards. This standardization makes test results from different laboratories and industries comparable and compatible.

Wide range of applications

Suitable for analyzing a variety of materials, including coarse particles. It is commonly used in industries such as mining, construction, pharmaceuticals, food processing and chemical engineering.

QC

By using the Φ200 standard inspection sieve, manufacturers can ensure the quality and consistency of their products. It enables them to monitor and control particle size distribution, ensuring the final product meets the required specifications.

efficiency and repeatability

When the Φ200 standard test sieve is used in conjunction with other sieves of different mesh sizes, the particle size distribution can be analyzed step by step. This process is efficient, repeatable, and helps identify any deviations or inconsistencies in the material being tested.

Durability and longevity

Φ200 standard test sieves are usually made of high-quality materials, such as stainless steel or brass, which ensures their durability and lifespan. This makes it a cost-effective investment for long-term use.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

Screen: The screen is a relatively technical part of the Φ200 standard test sieve. The most commonly used mesh type is stainless steel woven wire mesh. Opening sizes range from 5 inches (125 mm) to 635 mesh (20 microns).

Screen Frame: The frame is a circular metal ring that holds the mesh in place. The standard frame size in the United States is 8 inches. 200mm is the standard size internationally. The screen frame can be made of stainless steel or brass.

The Φ200 standard test sieve finds application in various industries and research fields for particle size analysis. Some of the common applications include:

Construction materials: In the construction industry, the Φ200 standard test sieve is used to analyze the particle size distribution of aggregates like sand, gravel, and crushed stone. This analysis helps ensure the quality and consistency of construction materials, such as concrete and asphalt.

Mining and minerals: The Φ200 standard test sieve is utilized in the mining and minerals industry to determine the particle size distribution of ores, minerals, and mineral powders. This information is crucial for optimizing mineral processing operations and ensuring the desired product quality.

Pharmaceuticals: In pharmaceutical manufacturing, the Φ200 standard test sieve is employed to analyze the particle size of active pharmaceutical ingredients (APIs), excipients, and drug formulations. This analysis helps ensure the uniformity and effectiveness of pharmaceutical products.

Food and beverage: The Φ200 standard test sieve is used in the food and beverage industry to measure the particle size of ingredients, such as flour, sugar, spices, and powders. This analysis is important for quality control, ensuring consistent texture, and optimizing processing parameters.

Chemical engineering: The Φ200 standard test sieve is applied in chemical engineering for analyzing the particle size distribution of various chemicals, powders, and granular materials. This information aids in process optimization, product quality control, and formulation development.

Skirt: The main purpose of the skirt is to allow the screens to stack without tipping over.

Dahan Machinery mainly produces Φ200 standard test sieve, Φ200 ultrasonic test sieve, Φ200 pharmacopoeia sieve, Φ200 soil sieve, Φ200 sand and gravel sieve and other experimental sieve professional testing and screening instruments.

Ready stock supply: Dahan is a direct sales manufacturer, with sufficient product models in stock, and can also support special model designs.

Quality Guarantee: 30-day warranty for quality problems. The warranty period for the whole machine is 1 year. If there is a quality problem during this period, our factory will provide free maintenance services.

Fast delivery: Standard parts are in stock, and special customization takes 7 working days. The delivery is fast and the cycle is guaranteed.

Service guarantee: 7*24-hour service response, clear reply within 1 hour, 72-hour on-site maintenance.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.