It can be used for the screening and testing of various pharmaceuticals, raw materials, pellets, Chinese medicine powders, Chinese medicine granules, and pills. There are 9 different meshes in a set of pharmacopoeia sieves.

![]()

![]()

![]()

Price:$23.00-$850.00/Set

Consult now and enjoy a 10% discount

Frame diameter:500/400/300/200/120/80/75mm, or others as your requirements.

Surface type: Woven Wire Mesh/Perforated Plate/Electroforming Mesh

Aperture sizes: 0.02-2.36mm

Screen type: wire woven mesh, metal perforated plate

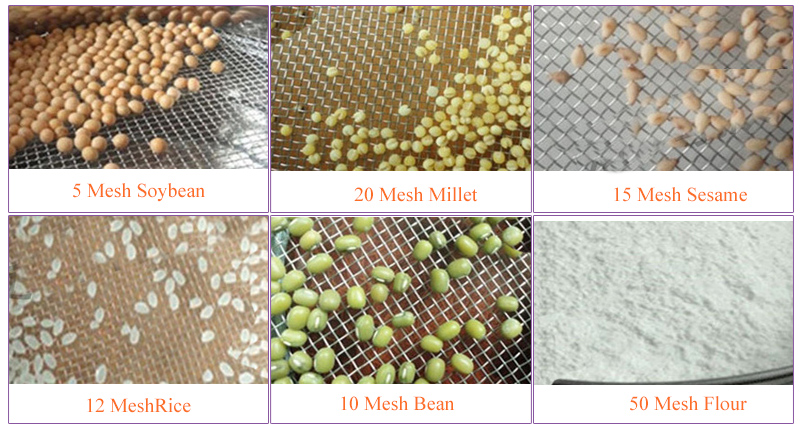

Mesh: 10 mesh, 24 mesh, 50 mesh, 65 mesh, 80 mesh, 100 mesh, 120 mesh, 150 mesh, 200 mesh

Commitment:

Standards pharmacopoeia sieve refers to the sieves used in the preparation process in accordance with the provisions of the Chinese Pharmacopoeia and the national unified specification, mainly used in the classification and screening process of traditional Chinese medicine and western medicine granules. Standards pharmacopoeia sieve can be hand sieved, and can also be used in conjunction with a test sieve to improve efficiency.

The standards pharmacopoeia sieve stipulated in the "Chinese Pharmacopoeia" are No. 1-9 (10 mesh-200 mesh), No. 1 sieve with large mesh, No. 2, No. 3, No. 4, No. 5, No. 6, No. 7, No. 8 , and the number 9 decreases in turn. The mesh numbers are: 10 mesh, 24 mesh, 50 mesh, 65 mesh, 80 mesh, 100 mesh, 120 mesh, 150 mesh, 200 mesh.

| Sieve Number | Aperture(μm) | Tolerance range (μm) | Mesh |

| S-1 | 2000 | ±70 | 10 mesh |

| S-2 | 850 | ±29 | 24 mesh |

| S-3 | 355 | ±13 | 50 mesh |

| S-4 | 250 | ±9.9 | 65 mesh |

| S-5 | 180 | ±7.6 | 80 mesh |

| S-6 | 150 | ±6.6 | 100 mesh |

| S-7 | 125 | ±5.8 | 120 mesh |

| S-8 | 90 | ±4.6 | 150 mesh |

| S-9 | 75 | ±4.1 | 200 mesh |

standards pharmacopoeia sieve for test pharmaceutical powder

Standards pharmacopoeia sieve with sieve machine

Standards pharmacopoeia sieve is used for classification, sieving, filtration and impurity removal of liquid, powder and granular drugs by traditional Chinese medicine, western medicine, preparation manufacturers or pharmacopoeia units.

| Pharmaceutical Powder Properties | Pass All | Mixed Pass |

| coarser powder | No. 1 sieve (10 mesh) | No. 3 (50 mesh) sieve not exceeding 20% |

| coarse powder | No. 2 sieve (24 mesh) | No. 4 sieve (65 mesh) no more than 40% powder |

| medium powder | No. 4 sieve (65 mesh) | No. 5 sieve (80 mesh no more than 60% powder |

| fine powder | No. 5 sieve (80 mesh) | No less than 95% powder with No. 6 sieve (100 mesh) |

| finer powder | No. 6 sieve (100 mesh) | No. 7 sieve (120 mesh) no less than 95% powder |

| very fine powder | No. 8 sieve (150 mesh) | No. 9 sieve (200 mesh) no less than 95% powder |

1. Metal wire woven mesh: a widely used type of screen mesh, usually customers buy this type of mesh because its cost is relatively low, the price is relatively low, and the flexibility is relatively good, but the accuracy is somewhat low, and the mesh size is relatively low. There is the possibility of deformation. Usually, the accuracy of the mesh is controlled by reaming and shrinking. It is mostly used in the diamond industry. more than 90 percent.

2. Metal punching plate mesh: The metal punching plate screen of the Pharmacopoeia screen is a screen that uses a punch to punch out the target pattern in the plate to be processed. There are also many kinds of materials, such as stainless steel, copper plate, aluminum plate. Compared with the ordinary woven screen, the screen of the punching plate is not easy to deform, wear-resistant, and has a relatively uniform precision. It is suitable for materials with high density, large impact on the screen surface and irregular shapes.

3. Electroforming mesh: It is usually manufactured by electrochemical method, and its accuracy is higher than the other two. In theory, its accuracy can reach 1 micron, the screen hole will not be deformed, the cleaning and maintenance time is relatively short, and the service life is relatively short. It is relatively long and has a better application in laboratories with high precision requirements.

1. A set of standards pharmacopoeia sieve consists of 9 sieves with different meshes, 1 non-perforated sieve, and 1 sieve cover (that is, the bottom and cover that are often referred to).

2. The screen frame is made of SUS304 (0Cr18ni9) stainless steel by stretching and polishing, the wall thickness is 0.6-0.7 mm, the surface light is recognizable, the overall shape is sturdy and durable, without magnetism, the screen mesh and the screen frame are fixed by tin welding, and will not loosen. It can withstand high temperature below 300 degrees.

3. The sieve mesh is a stainless steel woven mesh, the meshes conform to the GB6003.1-1997 standard, and are used after passing the inspection of tool microscopes, projectors and other equipment, which can ensure that the same type of standards pharmacopoeia sieve produced at any time has consistency and mutuality.

| Mesh number (mesh) | Aperture | Mesh number (mesh) | Aperture | Mesh number (mesh) | Aperture | Mesh number (mesh) | Aperture |

| 5 | 4mm | 40 | 0.45mm | 180 | 88μm | 325 | 34μm |

| 6 | 3.2mm | 50 | 0.355mm | 190 | 80μm | 360 | 40μm |

| 8 | 2.5mm | 60 | 0.3mm | 200 | 76μm | 400 | 38.5μm |

| 10 | 2mm | 70 | 0.25mm | 220 | 70μm | 500 | 30.8μm |

| 12 | 1.6mm | 80 | 0.2mm | 240 | 65μm | 600 | 25μm |

| 14 | 1.43mm | 100 | 0.15mm | 250 | 63μm | 800 | 15μm |

| 16 | 1.25mm | 120 | 0.125mm | 260 | 57μm | 900 | 10μm |

| 18 | 1mm | 140 | 0.105mm | 280 | 55μm | 1000 | 8μm |

| 20 | 0.9mm | 150 | 0.1mm | 300 | 50μm | 1200 | 5μm |

| 30 | 0.6mm | 160 | 97μm | 320 | 48μm | Bottom cover | Nonporous |

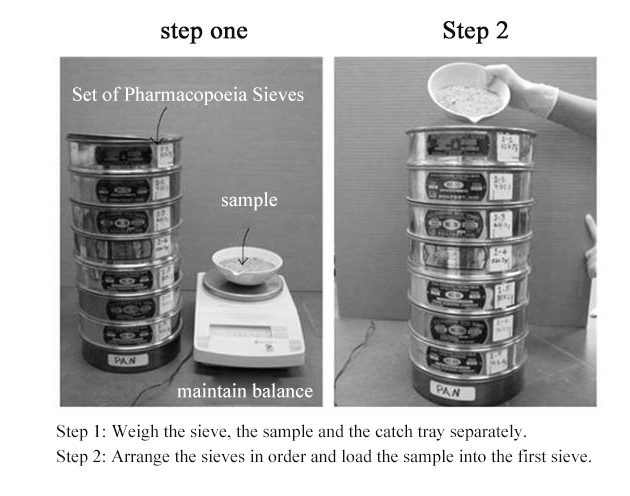

1. Stack the sieves of the standards pharmacopoeia sieve according to the aperture (mesh) from large to small, and stack them on the tray seat from top to bottom, and position the standard sieve by grooves or positioning screws.

2. Put the material to be inspected into the screen grid at the upper end, (or cover the upper cover), then press the screen grid with the screening head set on the wire column, and tighten the nut on the wire column to compress the screen grid. (Note: Both sides should be the same force, and then use the locking screw to lock.

3. Put the timer switch at the corresponding required position, (pay attention to reading the product manual, the set time is different for different settings), then turn on the power switch, and the inspection sieve starts to work.

4. After the work of the standards pharmacopoeia sieve stops, unscrew the nut on the thread column and carefully remove the sieve grid.

5. Cut off the power.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.