The screens generally used on test sieves are divided into woven wire mesh, punched plate screen and electroformed screen, among which the first two are the most common. This article will introduce the difference between woven wire mesh and punching standard sieve in detail:

1. Workmanship

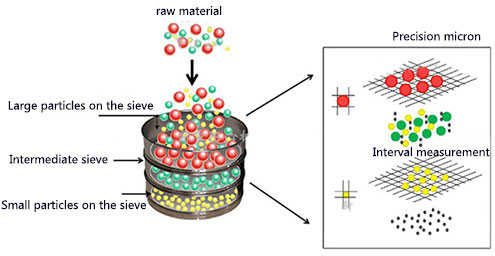

The woven wire mesh contains several individual wires woven together to create a square opening that allows for precise particle screening. These square openings are set at predefined intervals by the standards committee.

A punching standard sieve is a test sieve that uses galvanized or stainless steel sheet metal, with a few holes cut out to screen the particles. The holes are laser cut for precision and can be round or square in shape.

2. Mesh size

Woven wire mesh has a variety of mesh specifications to choose from. From 4 inches (100 mm) to 635 mesh (20 microns), woven wire mesh screens offer the level of precision required to maintain a reliable means of quality control, punching standard sieves have limitations due to the laser cutting process. Therefore, the hole diameter range of the perforated screen is only 125mm to 1mm. In other words, the woven wire mesh is ideal for those who require an accurate particle size distribution when testing product quality in a larger particle size range (from coarse to fine materials).

3. Durability

Because the perforated plate is constructed from a single sheet of steel rather than a single wire, perforated screens are more durable than woven wire mesh, which is especially useful in industries that test strong materials such as the aggregates industry.

The above is the difference between a woven wire mesh and a punching standard sieve, the screening media you integrate into your test sieve ultimately boils down to what your industry standard tells you to use. For example, there are specific aggregate tests around the world that specifically call for the punching standard sieve. When dealing with spectrally finer particles, a woven wire mesh is often used. That said, punching standard sieve is an ideal solution for unusually shaped particles.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.