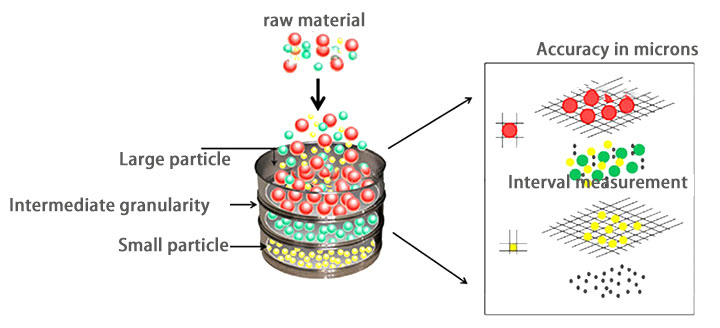

For laboratory classification and particle size determination of powders, bulk particles and suspensions

![]()

![]()

Price:$20.00-$3,680.00/Set/Set

Consult now and enjoy a 10% discount

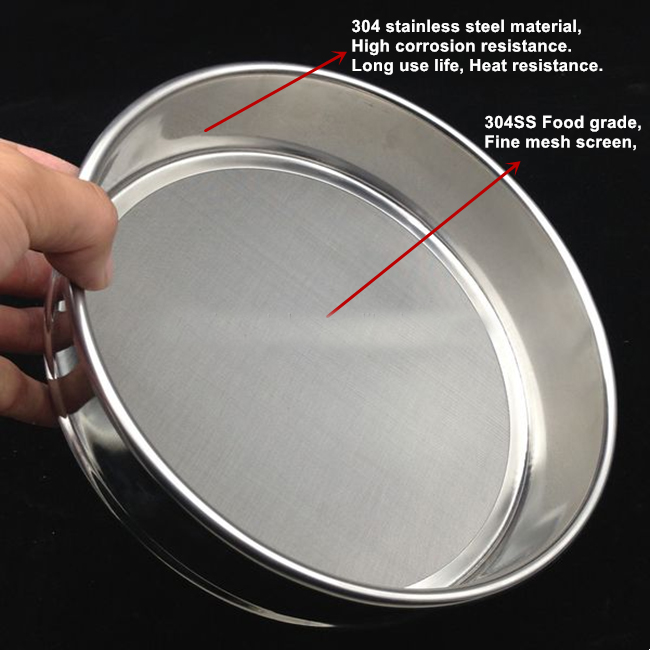

Material: stainless steel

Produced in strict accordance with GB6003.1-1997 or GB6003.2-1997

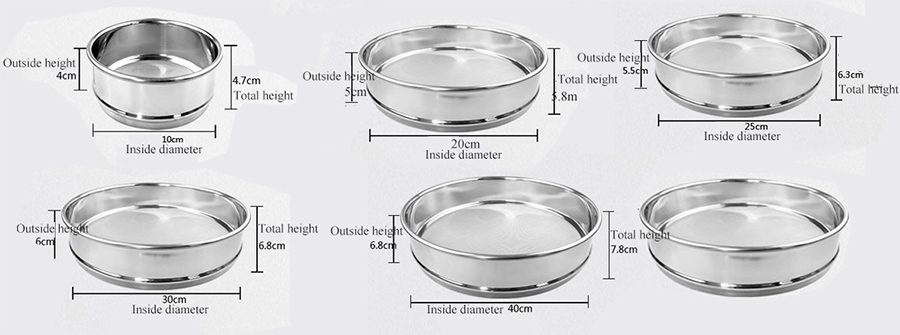

Diameter: 75/100/200/300mm/400mm/span>

Mesh size: 5μm-150mm

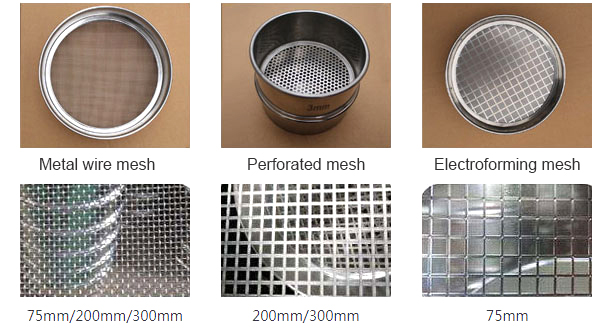

Screen type: woven mesh (0.02mm-2.36mm) / perforated plate (:1mm-125mm) / electroforming (75μm-5μm)

Weight: 45kg

Application: used for precise screening, filtration and detection of the particle size structure, liquid solid content and sundries of granular and powdery materials in laboratories, quality inspection rooms and laboratories of colleges and universities

Commitment:

Stainless steel test sieve is the equipment used in the laboratory environment to analyze and classify particles by size, it is made of stainless steel wire mesh, the frame is made of stainless steel, durable, corrosion resistant and easy to clean.

The stainless steel test sieve has a variety of sizes and meshes to choose from. The diameter of the screen frame is 75mm, 100mm, 200mm, 300mm, and 400mm. Plate test sieve (screen size 1mm-125mm), electroforming test sieve (screen size 5μm-500μm).

Stainless steel test sieves are used in a variety of particle size analysis applications in fields such as materials science, geology, and food science, often in combination with mechanical shakers or shaking tables, which apply controlled vibrations to the sieve to help separate particles by size. This process is called sieving or screening.

Stainless steel test sieves are used in a wide range of laboratory applications to analyze and classify particles by size. Some common applications for stainless steel test sieves include:

1. Material science: used to analyze the particle size distribution of powdery, granular and other substances. This information is important for understanding the properties of materials such as their flow, compressibility and bulk density.

2. Geology: used to analyze the particle size distribution of soil, sediment and rock samples. This information is important for understanding the properties of geological materials, such as their permeability, porosity and shear strength.

3. Food science: used to analyze the particle size distribution of food, such as flour, sugar and spices. This information is important for understanding the texture and consistency of food products and for quality control purposes.

4. Pharmaceuticals: used to analyze the particle size distribution of pharmaceutical powders and granules. This information is important for understanding the performance of drug products, such as their dissolution rate and bioavailability.

5. Environmental science: used to analyze the particle size distribution of environmental samples, such as air and water samples. This information is important for understanding the distribution and transport of pollutants in the environment.

Stainless Steel Test Sieve

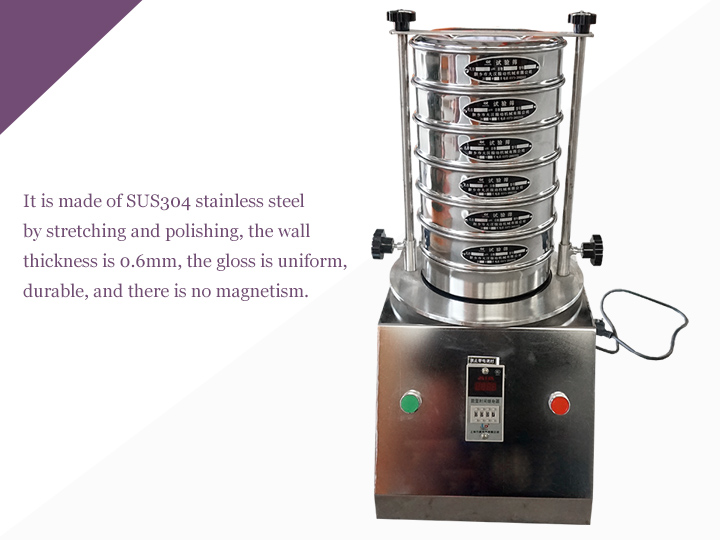

Stainless Steel Test Sieve shaker

Preservative

They are highly resistant to corrosion, which makes them ideal for use in harsh laboratory environments where there is constant exposure to chemicals or moisture.

Durability

Durable to withstand repeated use without deformation or loss of accuracy. In the long run, this makes them a cost-effective solution for particle size analysis.

Easy to clean

Easy to clean and sanitize to help prevent cross-contamination between samples. This is especially important in a laboratory setting where accuracy and repeatability are critical.

Precision and Accuracy

Provides precise and accurate particle size analysis, which is important for many laboratory applications. The uniformity of grid openings ensures consistent and accurate sorting of particles.

Custom made

Available in a variety of sizes and meshes, they can be customized for specific particle size analysis needs. This flexibility makes them ideal for a wide variety of laboratory applications.

Compliance

Many industries, such as pharmaceutical and food production, have stringent regulatory requirements for particle size analysis. Stainless steel test sieves meet these regulations and can be used with confidence in these applications.

Stainless steel, brass, and nylon test sieves are all used for particle size analysis, but they have some differences in performance and application. Here are some key differences between these types of test sieves:

| Difference | Stainless Steel Test Sieve | Brass Test Sieve | Nylon Test Sieve |

| Material | SUS304 stainless steel | Brass | Nylon |

| Durability | Most durable with high resistance to corrosion, abrasion and tearing | Also durable, but they are more prone to corrosion and wear over time | not durable |

| Mesh Size | 125mm-20μm | 10-350 mesh | 6-500 mesh |

| Cost | The most expensive | Cheaper | cheaper |

| Application | For laboratory applications including materials science, geology and food science | Used in applications where electrical conductivity is important, e.g. in the electronics industry | For applications where chemical resistance or flexibility are important, such as in the pharmaceutical or food industries. |

Stainless steel test sieve uses the YZU vertical vibration motor as the vibration source of the whole machine. The vibration motor drives the upper vibrating plate to vibrate, and then transmits the vibration through the vibrating plate to the screen frame on the upper part of the vibrating plate. The material particles with the sieve aperture are sieved to the lower sieve frame, so that only materials of the same particle size are left in each test sieve to achieve the separation of different particle sizes and determine the particle size composition of this material. The materials can be very effective for filtering, grading and screening purposes.

| Mesh shape | Diameter | Effective screen surface diameter | H | |

| Min | Max | |||

| round | 75mm | 75mm | 65mm | 25mm |

| 200mm | 200mm | 185mm | 25mm, 50mm | |

| 300mm | 300mm | 275mm | 75mm | |

| square | 300mm | 300mm | 75mm | |

The stainless steel test sieve consists of a frame made of stainless steel and a stainless steel wire mesh tensioned on the frame. The wire mesh forms a series of uniform openings or holes of a specific size, and the size of the openings can vary depending on the intended use of the sieve.

The frame of the screen is usually made of stainless steel for durability and corrosion resistance. The frame can be round or square, and it may have a lip or flange to aid in handling and prevent fraying of the wire mesh.

The wire mesh that forms the screen surface is also made of stainless steel for durability and corrosion resistance. The mesh is stretched tightly over the frame and then welded, crimped or glued to the frame to ensure it stays firmly attached.

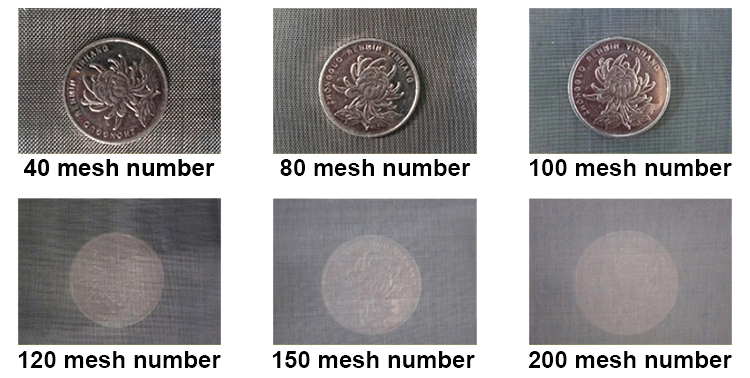

Wire mesh has uniform openings or holes of a specific size that allow particles smaller than the hole size to pass through. The size of the opening can vary depending on the intended use of the sieve, and sieves are usually marked with the opening size in microns or millimeters.

In addition to the frame and wire mesh, some stainless steel test sieves may have a cover or cover to prevent the particles from spilling during sieving. Some sieves also have a receiver or pan to collect particles that pass through the sieve.

Common sieve frame diameters of stainless steel test sieves are 75mm, 100mm, 200mm, 300mm, and 400mm, which are divided into wire woven mesh test sieves (screen size is 0.02mm-2.36mm), metal perforated plate test sieves (screen size is 1mm) -125mm), electroforming test sieve (screen size is 5μm-500μm).

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 | 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 | 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.