Precise sieving, filtering and detection of the particle size structure of granular and powdery materials, the content of liquid solids and the amount of sundries.

![]()

![]()

Price:$23.00-$850.00/Set

Consult now and enjoy a 10% discount

Hole shape: round

Diameter: 400/300/200/100/75mm or other requirements

Aperture sizes: 0.02-2.36mm

Screening particle size: 0.025-3mm

Material: stainless steel 304 / brass / chrome plated

Screen frame wall thickness: 0.6mm-0.7mm

Surface type: Woven Wire Mesh/Perforated Plate/Electroforming Mesh

Application: Used for particle size classification and detection of powder, granule or suspension, used in metallurgy, chemical industry, medicine, building materials, abrasives, cement, glass, grain, ceramics, papermaking and other industries as well as scientific research institutes for particle size analysis and screening test.

Commitment:

Round shaped sieves, also called Round sieves or round hole test sieves, is a sieve used to determine the particle size distribution of samples. It is a circular sieve with round holes of uniform size on the mesh surface. The size of the hole needs to be selected according to the particle size range. Round shaped sieves are commonly used in industries such as mining, pharmaceuticals and food processing where particle size analysis is critical for quality control and product development. They are available in various sizes and grid configurations to meet specific analysis requirements and standards. Round shaped sieves allow for a more efficient and consistent separation process than other shapes such as square or rectangular sieves.

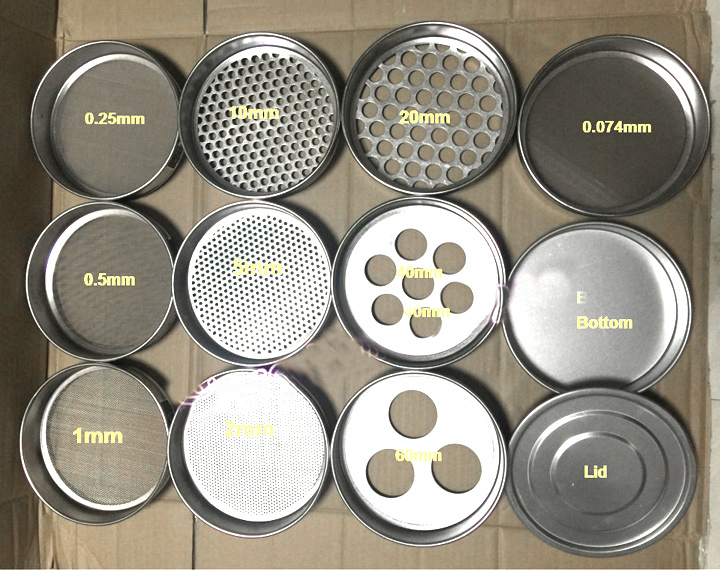

Common diameters are 75mm, 100mm, 200mm, 300mm, 400mm, which are divided into wire woven mesh test sieve (screen size is 0.02mm-2.36mm), metal perforated plate test sieve (screen size is 1mm-125mm), electric Forming test sieve (screen size 5μm-500μm).

| Dia.(mm) | Height(mm) | Frame | Bottom | Hole | Opening Size |

| 300 | 50 | Iron | Stainless Steel | Square / Round | Random |

| 300 | 50 | Stainless Steel | Stainless Steel | Square / Round | Random |

| Dia.(mm) | Height(mm) | Frame | Bottom | Hole | Opening Siz |

| 200 | 50 | Iron | Stainless Steel | Square / Round | Random |

| 200 | 50 | Stainless Steel | Stainless Steel | Square / Round | Random |

| 200 | 50 | Brass | Brass | Square / Round | ≤4mm |

| 200 | 50 | Brass | Stainless Steel | Square / Round | Random |

Higher accuracy

Known for its higher accuracy in particle size analysis. This is because the round shape distributes the sample evenly across the sieve, reducing the risk of particles accumulating in certain areas of the sieve which could affect the results.

More durable

Usually made of high-quality materials, they are more durable than other shapes of test sieves. This means they can withstand more wear and tear over time, making them a cost-effective investment in the long run.

Easy to clean

Usually easier to clean than other shapes of test sieves. Their smooth, round shape makes it easier to remove particles from the sieve, reducing the risk of residue buildup that could affect the accuracy of future tests.

Versatility

Suitable for a wide range of particle size analysis applications. They can be used with many types of materials including powders, granules and liquids, making them a versatile tool for many industries.

Compatibility

Compatible with a variety of sieve shakers, used for vibrating sieves to ensure particles pass through evenly. This makes them a convenient tool for many laboratories and testing facilities.

High temperature resistance

The screen mesh and screen frame are fixed by welding to prevent loosening and shaking, and can work stably at temperatures >300 degrees.

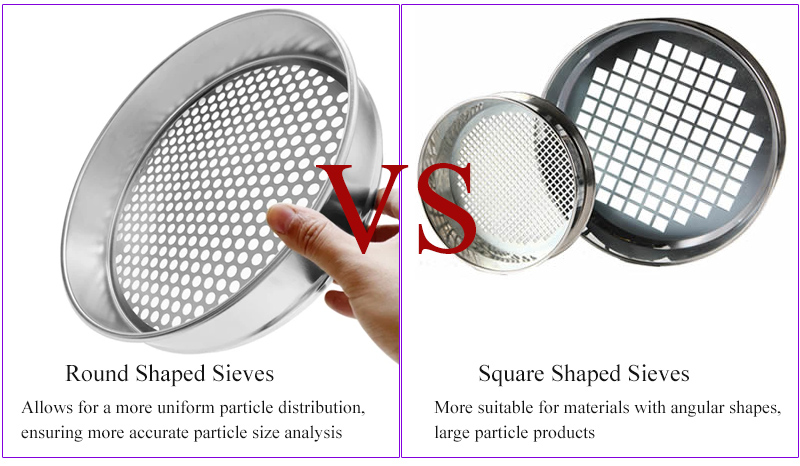

The main difference between round shaped sieves and square shaped sieves is the shape of the pores that filter the particles. Round shaped sieves have round holes, while square shaped sieves have square holes. Here are some other differences between the two sieves:

1. Particle Distribution: Round shaped sieves tend to distribute particles more evenly across the screen compared to square hole test sieves. This is because round holes reduce the chances of particles getting trapped in corners or edges.

2. Accuracy: round shaped sieves generally provide more accurate results than square hole test sieves. This is because circular holes allow for a more uniform particle distribution, reducing the possibility of particle buildup and ensuring more accurate particle size analysis.

3. Material properties: The choice of round holes and square shaped sieves usually depends on the properties of the material being analyzed. For example, powder and granular materials may flow more easily through round holes, while materials with angular shapes may be better suited for square shaped sieves.

4. Cleaning: round shaped sieves are generally easier to clean than square shaped sieves because the round shape removes particles more easily from the sieve surface.

5. Usability: square shaped sieves are more widely used than round shaped sieves because they are often used in industries such as construction and mining for the separation of larger particles. Round shaped sieves are more commonly used in industries such as pharmaceuticals and food processing where greater precision is required for particle size analysis.

Round shaped sieves are a versatile tool for particle size analysis in a wide range of industries and applications. They provide invaluable information on material quality, performance and suitability for various applications including:

1. Mining industry: Analyzing and grading minerals and other materials according to their particle size distribution. This information is critical to optimizing mineral processing operations and improving product quality.

2. Pharmaceutical industry: used in the pharmaceutical industry to determine the particle size distribution of pharmaceutical powders and granules. This information is critical to ensuring consistent drug potency and efficacy.

3. Food industry: It is used in the food industry to determine the particle size distribution of food ingredients such as flour, sugar, and spices. This information is critical to ensuring consistent product quality and shelf life.

4. Environmental industry: Used in the environmental industry to determine the particle size distribution of soil and sediment samples, which can provide valuable information about soil composition and erosion.

5. Construction industry: It is used in the construction industry to analyze and classify aggregates such as sand and gravel according to the particle size distribution. This information is critical to ensuring the quality and strength of concrete and other building materials.

| Sieve Designation | Nominal Sieve Opening | |||

| Standard | Mesh | inches | mm | Microns |

| 25.4 mm | 1 in. | 1.00 | 25.4 | 25400 |

| 22.6 mm | 7/8 in. | 0.875 | 22.6 | 22600 |

| 19.0 mm | 3/4 in. | 0.750 | 19.0 | 19000 |

| 16.0 mm | 5/8 in. | 0.625 | 16.0 | 16000 |

| 13.5 mm | 0.530 in. | 0.530 | 13.5 | 13500 |

| 12.7 mm | 1/2 in. | 0.500 | 12.7 | 12700 |

| 11.2 mm | 7/16 in. | 0.438 | 11.2 | 11200 |

| 9.51 mm | 3/8 in. | 0.375 | 9.51 | 9510 |

| 8.00 mm | 5/16 in. | 0.312 | 8.00 | 8000 |

| 6.73 mm | 0.265 in. | 0.265 | 6.73 | 6730 |

| 6.35 mm | 1/4 in. | 0.250 | 6.35 | 6350 |

| 5.66 mm | No. 3 1/2 | 0.223 | 5.66 | 5660 |

| 4.76 mm | No. 4 | 0.187 | 4.76 | 4760 |

| 4.00 mm | No. 5 | 0.157 | 4.00 | 4000 |

| 3.36 mm | No. 6 | 0.132 | 3.36 | 3360 |

| 2.83 mm | No. 7 | 0.111 | 2.83 | 2830 |

| 2.38 mm | No. 8 | 0.0937 | 2.38 | 2380 |

| 2.00 mm | No. 10 | 0.0787 | 2.00 | 2000 |

| 1.68 mm | No. 12 | 0.0661 | 1.68 | 1680 |

| 1.41 mm | No. 14 | 0.0555 | 1.41 | 1410 |

| 1.19 mm | No. 16 | 0.0469 | 1.19 | 1190 |

| 1.00 mm | No. 18 | 0.0394 | 1.00 | 1000 |

| 0.841 mm | No. 20 | 0.0331 | 0.841 | 841 |

| 0.707 mm | No. 25 | 0.0278 | 0.707 | 707 |

| 0.595 mm | No. 30 | 0.0234 | 0.595 | 595 |

| 0.500 mm | No. 35 | 0.0197 | 0.500 | 500 |

| 0.420 mm | No. 40 | 0.0165 | 0.420 | 420 |

| 0.354 mm | No. 45 | 0.0139 | 0.354 | 354 |

| 0.297 mm | No. 50 | 0.0117 | 0.297 | 297 |

| 0.250 mm | No. 60 | 0.0098 | 0.250 | 250 |

| 0.210 mm | No. 70 | 0.0083 | 0.210 | 210 |

| 0.177 mm | No. 80 | 0.0070 | 0.177 | 177 |

| 0.149 mm | No. 100 | 0.0059 | 0.149 | 149 |

| 0.125 mm | No. 120 | 0.0049 | 0.125 | 125 |

| 0.105 mm | No. 140 | 0.0041 | 0.105 | 105 |

| 0.088 mm | No. 170 | 0.0035 | 0.088 | 88 |

| 0.074 mm | No. 200 | 0.0029 | 0.074 | 74 |

| 0.063 mm | No. 230 | 0.0025 | 0.063 | 63 |

| 0.053 mm | No. 270 | 0.0021 | 0.053 | 53 |

| 0.044 mm | No. 325 | 0.0017 | 0.044 | 44 |

| 0.037 mm | No. 400 | 0.0015 | 0.037 | 37 |

Dahan round shaped sieves manufacturer has 15 years of production experience. The specifications are 200mm×50mm or 200mm×25mm optional; sieves include woven mesh, punched plate mesh and electroforming, etc.; factory direct sales, the price starts as low as $50

Address:China,Yanjin county forest park gate to the west 1000 meters north road.