standard test sieve

standard test sieve stainless steel standard test sieve

stainless steel standard test sieve brass standard test sieve

brass standard test sieve Metal wire standard test sieve

Metal wire standard test sieve Metal perforated plate standard test sieve

Metal perforated plate standard test sieve

Accurate screening, filtering and testing of granular, powdery materials and liquid solids in the laboratory

![]()

![]()

![]()

Price:$23.00-$850.00/Set

Consult now and enjoy a 10% discount

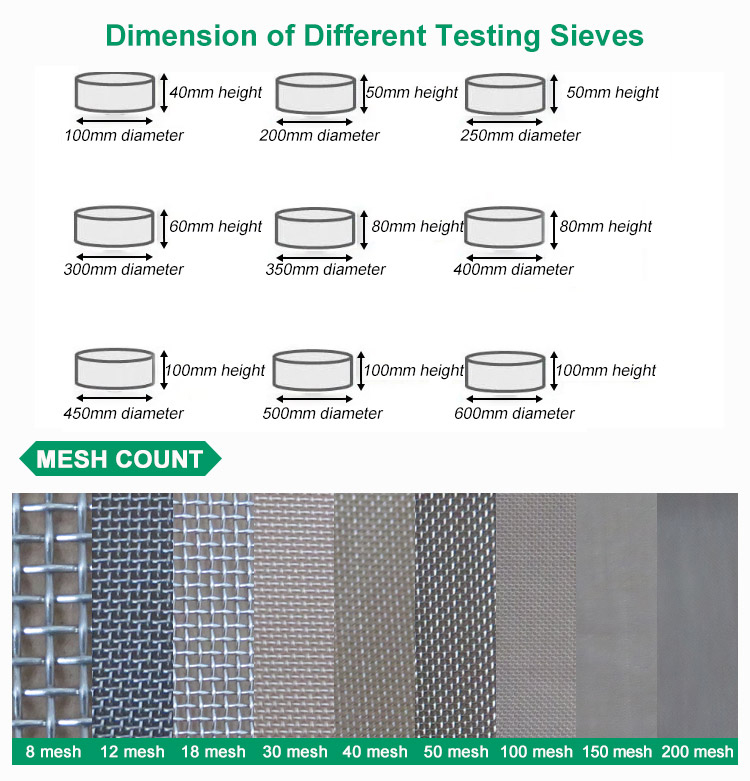

Frame diameter:500/400/300/200/120/80/75mm,or others as your requirements.

Surface type:Woven Wire Mesh/Perforated Plate/Electroforming Mesh

Aperture sizes:0.02-2.36mm

Hole shape:Square/Round

Material:Stainless steel304/Brass/Chromeplate

International standard: ISO3310-1:1990 R20/3, R20, R40/3 series

Commitment:

Standard test sieve is a specialized tool used in particle size analysis to determine the particle size distribution of a sample. It is a flat, circular sieve with uniform mesh openings of specific sizes, constructed from durable materials such as stainless steel or brass.

Standard test sieves are available in various mesh sizes, typically ranging from coarse to fine, and are used in laboratories for classification and particle size determination of powders, bulk granules and suspensions. With the help of standard test sieves, solid particle sizes from 125mm to 20μm can be measured quickly and efficiently.

Standard test sieves are used for particle size analysis and classification of granular materials. These sieves are usually made of brass, stainless steel or other materials with precise mesh size, which allows particles of a certain size to pass through, while larger particles are retained. The following are some common uses of standard test sieves:

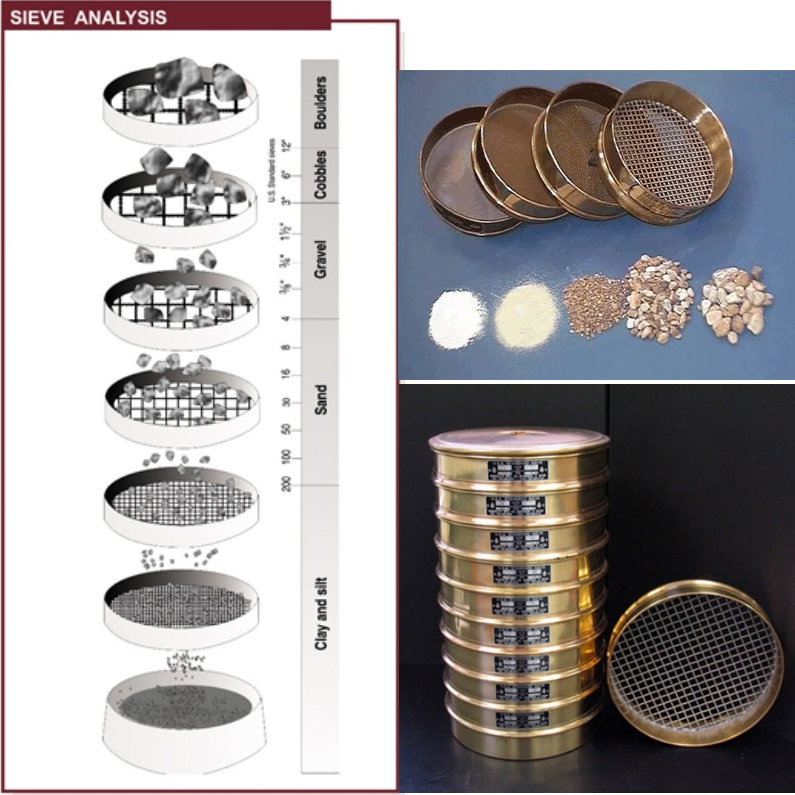

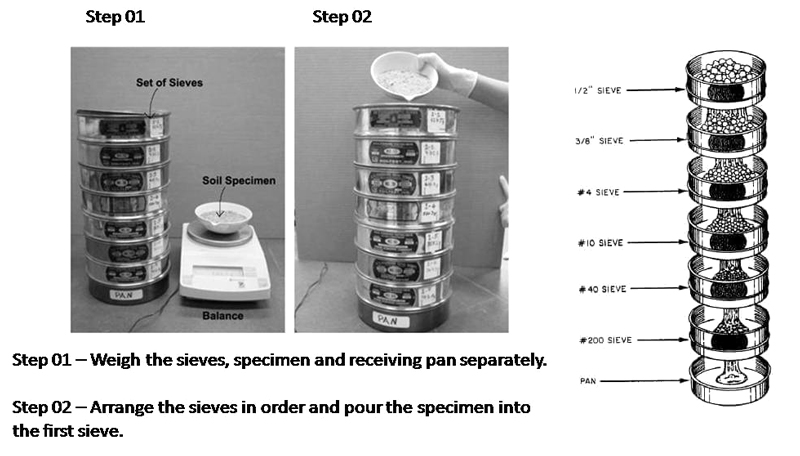

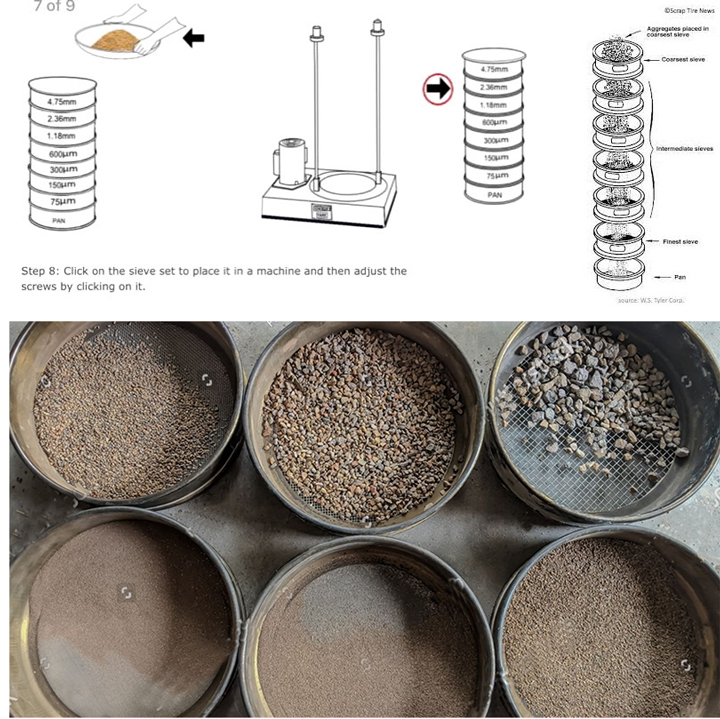

Particle Size Analysis: Standard test sieves are used to determine the particle size distribution of materials. By passing a sample through a series of stacked sieves with progressively smaller openings, particles are separated based on size, allowing for analysis of the distribution of particle sizes within the material.

Quality Control: They are used in quality control processes to ensure that the particle size of a material meets the specifications required for a specific application. For example, in the pharmaceutical industry, sieves are used to ensure the uniformity of powdered medicines.

Aggregate Testing: Determines the particle size distribution of aggregates in concrete and asphalt mixes. This helps ensure the quality and performance of the final product.

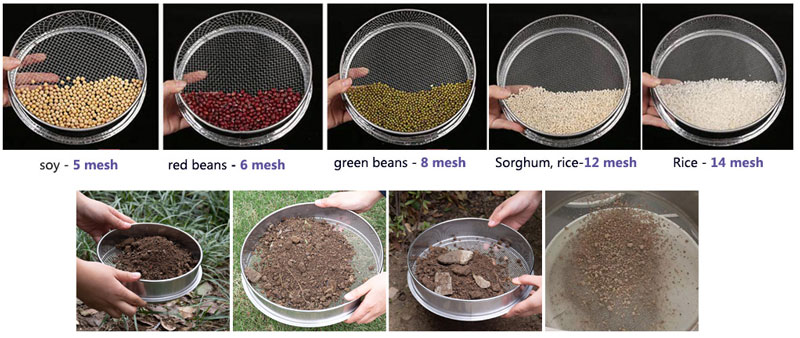

Soil Analysis: Analyzes the particle size distribution of soil.

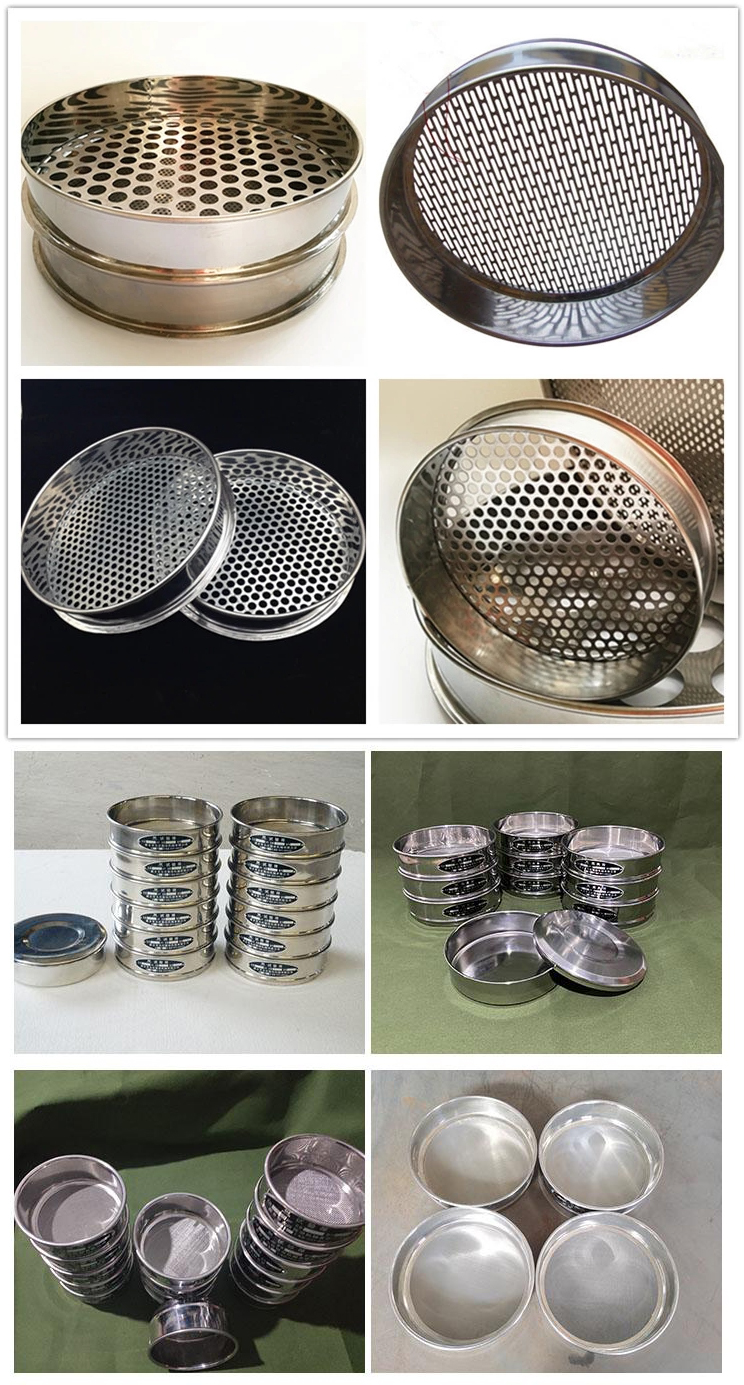

There are several types of standard test sieves available, each designed for a specific testing application. Some common types of standard test sieves include:

1. Brass Frame Test Sieves: These sieves are made of brass frame and stainless steel mesh screen. They are commonly used for particle size analysis of materials in the construction industry, such as aggregates and concrete.

2. Stainless steel frame test sieve: This type of sieve has a stainless steel frame and mesh screen, and is often used for particle size analysis of powdery and granular materials in pharmaceutical, food processing, chemical and other industries.

3. Nylon Frame Test Sieve: This sieve has a nylon frame and mesh screen and is used for particle size analysis of fine powders and materials that may be damaged by metal sieves.

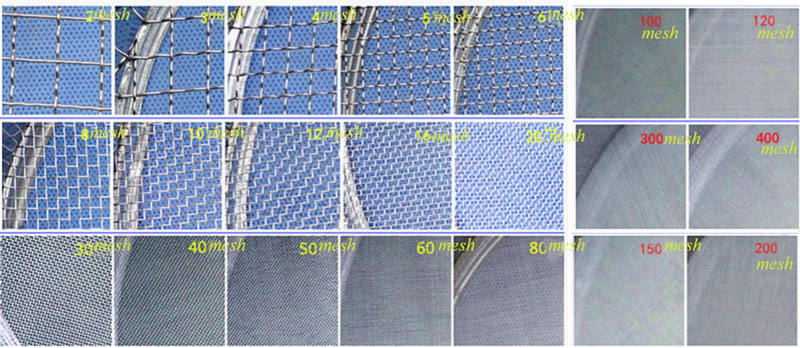

4. Wire Woven Mesh Test Sieve: widely used, low cost, only square mesh, mesh size from 2.36 mm to 0.02 mm.

5. Metal Perforated Plate Test Sieve: mainly used for large mesh, there are two types of mesh holes, round hole and square hole, the mesh size is from 0.2 to several hundred millimeters, the mesh precision is uniform, and it is not easy to deform.It is mainly used for the detection of large particles.

6. Electroforming Test Sieve: It is mainly used in high-precision occasions, and each mesh can be within the average error range, and the theoretical accuracy can reach one micron.

Standard test sieves separate particles according to particle size. A sieve consists of a circular frame made of metal or plastic with a mesh screen in the middle. Screens are made of wire weave or stainless steel and have uniform openings of specified size.

To use a standard test sieve, place a sample of material on top of the sieve and shake or tap the sieve to allow the smaller particles to pass through the mesh and collect in a container placed below. Larger particles are retained at the top of the sieve and weighed to determine the percentage of material in each size range.

The pore size of the sieve determines the particle size range that can pass through the sieve. For example, a screen with a mesh size of 100 will allow particles smaller than 100 microns to pass through while retaining particles larger than 100 microns at the top of the screen.

standard test sieves for flour

standard sieve shaker for aggregate

components of standard test sieve

| Mesh shape | Diameter | Effective screen surface diameter | H | |

| Min | Max | |||

| round | 75mm | 75mm | 65mm | 25mm |

| 200mm | 200mm | 185mm | 25mm, 50mm | |

| 300mm | 300mm | 275mm | 75mm | |

| square | 300mm | 300mm | 75mm | |

1. Mesh number: refers to the size of the mesh holes, which is the main feature to distinguish different types of sieves. Mesh size is measured in microns or millimeters and ranges from very fine to coarse.

2. Frame Material: Can be made from a variety of materials including stainless steel, brass or plastic. The frame material affects the durability and corrosion resistance of the screen.

3. Screen material: It can be made of various materials, including wire mesh, stainless steel or nylon. The screen material affects the accuracy, durability and corrosion resistance of the screen.

4. Diameter: Diameter refers to the size of the circle frame, from small to large. The diameter of the sieve is usually selected according to the amount of material being tested and the testing equipment used.

5. Height: refers to the distance from the top of the screen frame to the bottom of the screen. Height affects the amount of material that can be loaded onto the screen and the accuracy of particle size analysis.

6. Certification: Some standard test sieves may be certified to specific industry standards, such as ASTM or ISO, to ensure consistent mesh size and tolerances for each sieve. Certification can provide additional assurance of accuracy and reliability.

| NO. | Name | Application | Specification |

| 1 | Standard soil sieve | Analyzing the particle size distribution of soil, it is possible to separate soils of different fineness | 0.075mm, 0.25mm, 0.5mm, 1mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm, 10mm, 12mm, 13mm, 20mm, 40mm, 60mm |

| 2 | Standard gravel screen | Determination of sand, silt and clay | 2.5, 5, 10, 16, 20, 25, 31.5, 40, 50, 63, 80, 100mm, with bottom cover or 2.36, 4.75, 9.5, 16, 19, 26.5, 31.5, 37.5, 53, 63, 75, 90mm, with bottom cover |

| 3 | Standard pharmacopoeia sieve | Analysis and testing of pharmaceutical powders, pharmaceuticals, and pharmaceutical granules | 10 mesh, 24 mesh, 50 mesh, 65 mesh, 80 mesh, 100 mesh, 120 mesh, 150 mesh, 200 mesh |

| 4 | Standard stone sieve | For determination of particle size distribution of sand, aggregates, soil | 1, 1.7, 2.5, 3.15, 5, 7.1, 10, 16, 20, 25, 35.5, 40, 45, 56, 63mm |

| 5 | Standard cement sieve | Check the fineness of cement | A total of 5 pieces, including the bottom and cover, the specifications are 0.125, 0.71, 0.9, 5, 20mm |

| 6 | Standard aggregete sieve | Determining aggregate particle size distribution | 80, 60, 50, 40, 30, 25, 20, 10, 5, 2, 1, 0.5, 0.2, 0.075mm |

Featured materials

Made of SUS304 stainless steel, it is resistant to acid and alkali, high temperature, low temperature, not easy to rust, and can withstand high temperatures below 300 degrees.

Precise mesh

The square hole can reach 0.02mm (20 microns) and the triangular hole mesh size can reach 0.005mm (5 microns), which conforms to the international standard ISO3310-1: 1990 R20/3, R20, R40/3 series.

High detection accuracy

It can be sieved to 0.025-3mm, and 8 layers of standard test sieve frames can be installed.

Available time

With a time relay, it can be timed to ensure the consistency and accuracy of the entire experiment.

Easy to clean

The design is simple and easy to clean, convenient for maintenance and upkeep, ensuring a hygienic and clean screening process.

Diversity

Provide screen mesh selections of various specifications and materials to adapt to the screening needs of different particle sizes and characteristics.

| No. | Type | Mash(mm) | No. | Type | Mash(mm) |

| 1 | 8# | 2.360 | 17 | 100# | 0.150 |

| 2 | 11# | 2.000 | 18 | 120# | 0.125 |

| 3 | 12# | 1.700 | 19 | 140# | 0.106 |

| 4 | 14# | 1.400 | 20 | 170# | 0.09 |

| 5 | 16# | 1.180 | 21 | 200# | 0.075 |

| 6 | 18# | 1.000 | 22 | 230# | 0.063 |

| 7 | 20# | 1.850 | 23 | 270# | 0.053 |

| 8 | 25# | 0.710 | 24 | 325# | 0.045 |

| 9 | 30# | 0.600 | 25 | 400# | 0.038 |

| 10 | 35# | 0.500 | 26 | 500# | 0.028 |

| 11 | 40# | 0.425 | 27 | 635# | 0.020 |

| 12 | 45# | 0.355 | 28 | 700# | 0.018 |

| 13 | 50# | 0.300 | 29 | 800# | 0.015 |

| 14 | 60# | 0.250 | 30 | 1000# | 0.01 |

| 15 | 70# | 0.180 | 31 | 1250# | 0.005 |

| 16 | 80# | 0.180 | 32 | 1800# | 0.003 |

Standard test sieves are used in a wide range of industries and applications to determine the particle size distribution of materials. Some common applications of standard test sieves include:

1. Construction materials: used to analyze the particle size distribution of aggregates, such as sand, gravel and crushed stone, to ensure that they comply with specific standards and specifications.

2. Pharmaceutical industry: used to analyze the particle size distribution of powder and granular materials used in pharmaceutical manufacturing. This information is used to ensure the size and consistency of the material, which is important for dosage accuracy and efficacy.

3. Food processing: used to analyze the particle size distribution of powdery and granular materials, such as flour and sugar, to ensure that they meet specific standards and specifications.

4. Environmental testing: Use standard test sieves to analyze the particle size distribution of soil and sediment samples. This information is used to assess soil quality and determine the presence of pollutants.

5. Research and development: For research and development to analyze the particle size distribution of various materials, including polymers, ceramics and metals. This information is used to optimize manufacturing processes and develop new materials with specific properties.

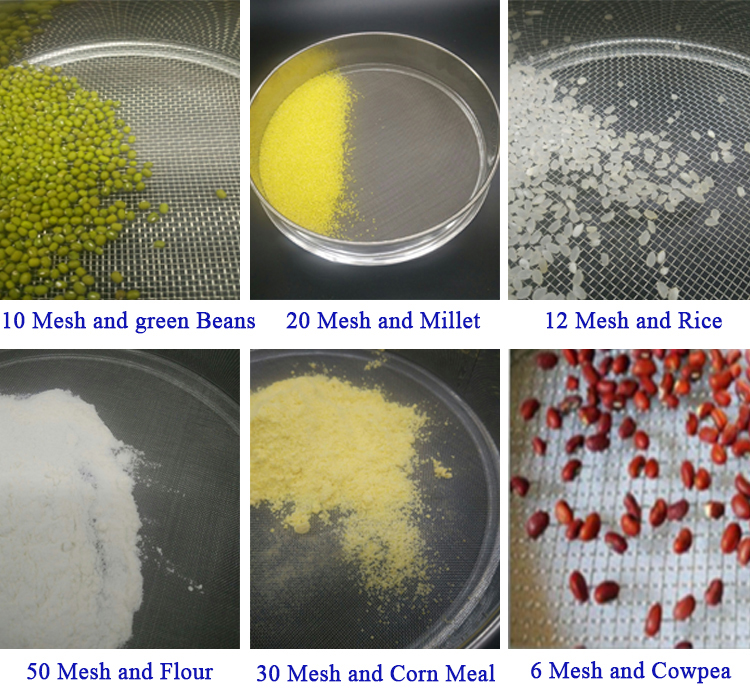

The available test sieve options following are specific applications:

| Product | Mesh size | Product | Mesh size | Product | Mesh size |

| Cassia | 14 mesh | Buckwheat | 12 mesh | Tenebrio eggs | 12 mesh |

| Insect droppings | 30 mesh | Soybean | 4-5 mesh | Green beans | 10 mesh |

| Rice | 12-14 mesh | Rice flour | 30-40 mesh | Cornmeal | 30-40 mesh |

| Flour | 50-60 mesh | Cereals | 40-50 mesh | Sesame | 22-24 mesh |

| Fried Chicken Burger Bread | 20-30 mesh | Mung bean powder | 40-50 mesh | Sesame powder | 40-50 mesh |

| Notoginseng powder | 100-120 mesh | Pine Pollen | 100-120 mesh | Chinese medicine powder | 40-50 mesh |

| Oral Chinese medicine powder | 60-80 mesh | Chinese Herbal Mask | 80-120 mesh | Pearl powder | 120-150 mesh |

| Dregs | 60-150 mesh | Soy milk | 80-120 mesh | Honey | 80-120 mesh |

| Soup dregs | 120-150 mesh | Tea water | 120-150 mesh | Cooking oil | 150-200 mesh |

Xinxiang Dahan Vibration Machinery Co., Ltd. mainly produces standard test sieves, standard soil sieves, standard pharmacopoeia sieves, standard gravel sieves, standard aggregate sieves, etc. Suitable for scientific research and production in building materials, national defense, geological and other departments, laboratories, quality inspection rooms, laboratories of colleges and universities to screen the particle size structure, liquid solid content, and debris amount of granular and powdery materials. Filtration testing is also commonly used in Common abrasive particle size composition detection and superhard material production and classification and other fields.

The manufacturer promises: standard parts are in stock, special customization takes 7 working days, free delivery by the manufacturer, if there is a quality problem within 30 days, the user can choose free repair or replacement, one-year warranty, lifetime warranty.

The primary standards for standard test sieves are:

ASTM standard test sieves: Available in a variety of mesh sizes, with frames and mesh made of stainless steel, brass, or a brass combination frame and stainless steel cloth. These sieves meet ASTM E11 and AASHTO M92 requirements. The choice of frame diameter and full-height or half-height configuration depends on sample volume and particle size.

ISO standard test sieves: Based on SI or metric sizes, with 200 mm or 300 mm diameters, all ISO mesh sizes are available. These sieves meet ISO 565 and 3310-1 specifications. They are made of stainless steel frame and mesh or brass frame and stainless steel mesh, and are available in full-height or half-height sizes.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.