Test sieve is a common tool for particle size analysis of granular powder materials in the laboratory. There are different types of test sieve screen mesh. According to actual needs and use environment, choose the appropriate sieve type for particle analysis and sieving experiments. So what are the classifications of the test sieves? The following is the relevant introduction:

Under normal circumstances, we divide the test sieve grid into the following three categories according to the different manufacturing processes of the screen:

Frame diameter: ø 75 / 200 mm / 300 mm

Mesh type: Metal mesh

Mesh size: 0.02 mm - 2.36 mm

Standard: GB/T6003.1-1997/ISO3310.1

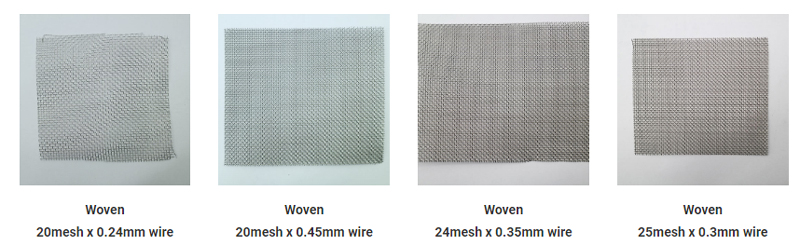

Wire woven mesh screens are the most widely used in laboratory vibrating screens and industrial vibrating screens. The mesh shape of this type of screen can only be square holes, and the mesh size is between 2.36 mm and 0.02 mm. Applicable mesh has a large mesh size, because its relative accuracy is the lowest (allowing large mesh), and the mesh may be deformed with the increase of service life. Because the flexibility of the wire is strong, it should be protected during use. And replace it regularly to avoid impaired accuracy due to mesh deformation.

Advantages: It has the characteristics of low cost, wide application range, light weight and durability.

Frame diameter: ø 200 mm / 300 mm

Mesh type: Perforated plate

Grid size: 1 mm - 125 mm

Standard: GB/T6003.2-1997/ISO3310.2

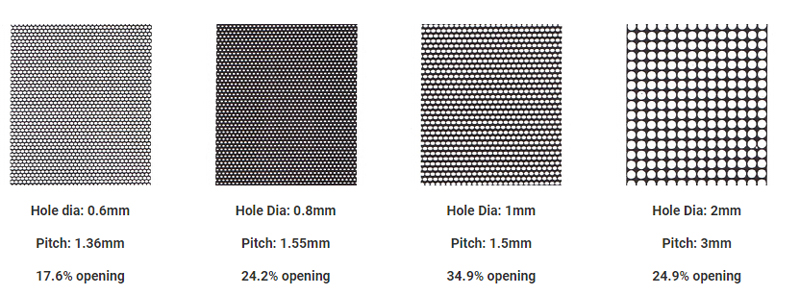

Metal perforated screens, also known as slab screens, are a type of test sieve screen that is punched directly into the fixed shape and size of the sieve hole on the steel plate or other sieve material. Orifice sieve screens are mostly square or round, and customers can customize according to their own materials.

Advantages: It is safe and firm, and it is suitable for materials with relatively high density and large impact on the screen surface and irregular shape.

Frame diameter: ø 75 mm / 200 mm

Mesh type: electroforming

Mesh size: 5μm - 500μm

Standard: GB/T6003.3-1999/ISO3310.3

This kind of screen is produced by electrochemical method with the highest precision. The theoretical precision can reach one micron, but the corresponding cost is also high. It has a good application in high precision laboratory scenes.

Advantages: high precision, but not good flexibility, easy to break, high cost.

The screen produced by Dahan test sieve manufacturer is in line with national standards. The screen frame is made of stainless steel (SUS304), the quality is guaranteed, and the screening is accurate. If you have special requirements, we can design and produce according to your requirements.

In addition, test sieves are also divided into stainless steel, brass and nylon materials. Test sieves of different materials are suitable for different experimental needs and environments.

Stainless steel: It has corrosion resistance and wear resistance, and is suitable for a variety of particle analysis and screening experiments.

Brass: It is used to analyze specific particles and has certain corrosion resistance and conductivity.

Nylon: It is suitable for analyzing certain metal-sensitive particles and has good durability and chemical resistance.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.