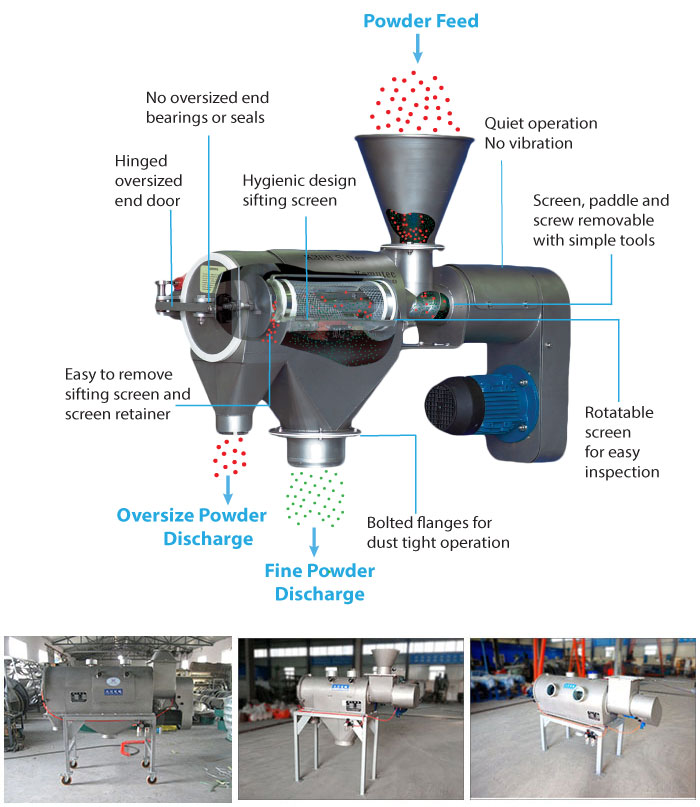

Used for safe screening of products, removing foreign matter, breaking up lumps

![]()

![]()

Price:$900.00-$5,700.00/Set

Consult now and enjoy a 10% discount

Screen size: 80-500 mesh

Capacity: 1~10 tons/hour

Power: 2.2-5.5KW

Screen cylinder perforation size: 0.15-10mm

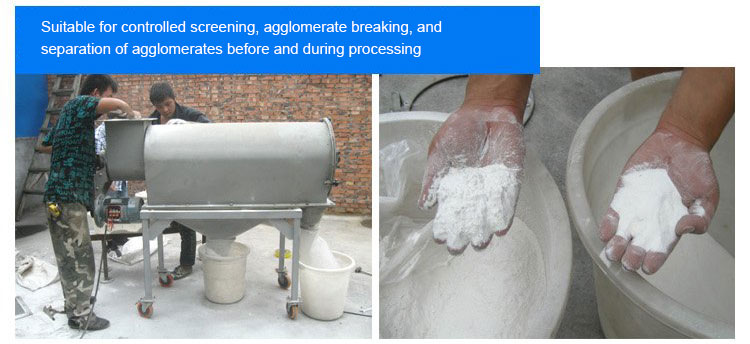

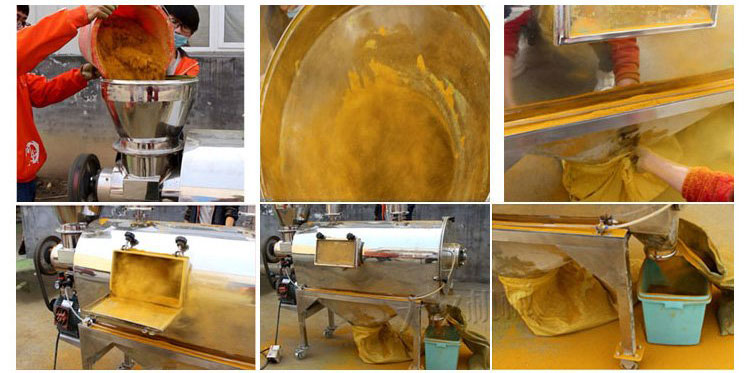

Application: It is suitable for sieving ultra-fine powders with light specific gravity, high viscosity, many fibers, static electricity, and easy to agglomerate, such as pharmaceutical powder, metal powder, food powder, chemical powder, electromagnetic powder, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

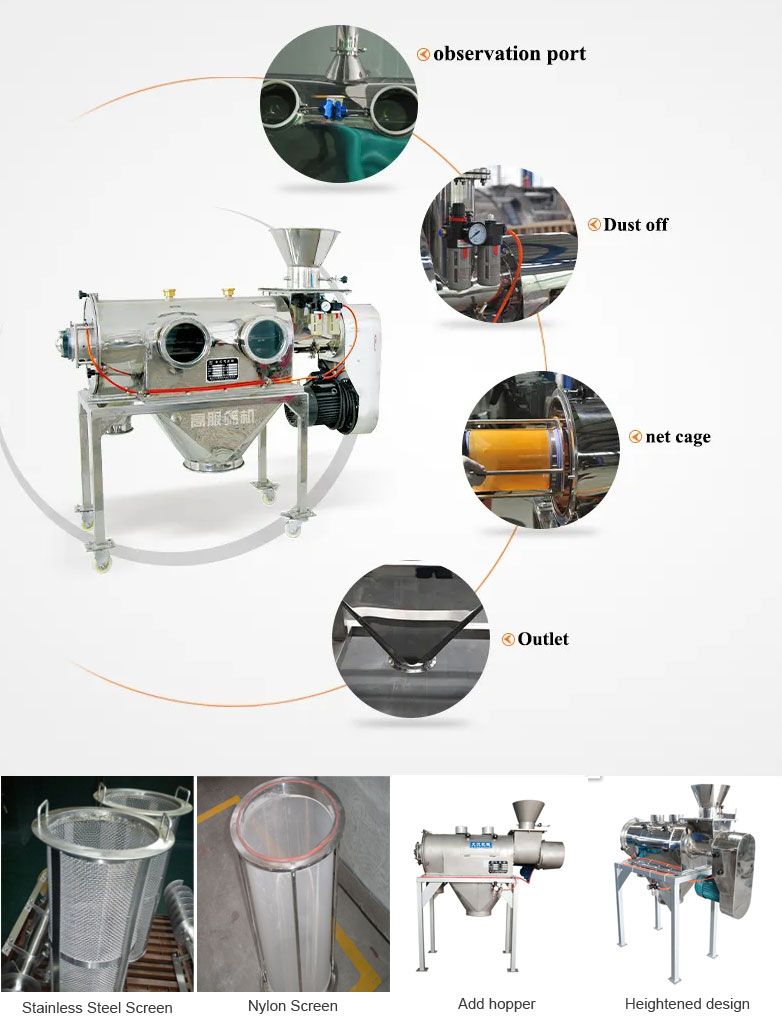

Cyclone screener can continuously screen powder materials in the range of 60-500 mesh fineness, suitable for a wide range of fineness, and the screen can be replaced at will. The machine can be matched with the pneumatic conveying system, and can be directly connected to the air duct. It has the function of airflow feeding, the feeder crushing agglomerate and the airflow coarse screening function. The advantage is that the investment and operation and maintenance of the feeding machine are saved for customers. Cost, the life of the fine screen is extended by more than 10 times, the output is steadily increased, the power consumption is reduced, and the quality of the finished powder passing through the screen is better.

The main function of the cyclone screener is to use centrifugal force to separate particles from a gas or liquid stream. Some of the main features of a cyclone screen include:

1. Particle Separation: Using differences in particle size, shape and density to separate particles from a gas or liquid stream. The separated particles can then be collected and removed from the system.

2. Particle classification: Can be used to classify particles according to their size or other physical properties. This allows the separation of particles into fractions of different sizes or the removal of particles with specific physical properties.

3. Particle Size Reduction: Can be used to reduce the size of particles by breaking them down into smaller particles. This is achieved by subjecting the particles to centrifugal force, causing them to collide with each other and break apart.

4. Deagglomeration: Cyclone sifters can be used to break down particle clumps or aggregates into smaller individual particles. This is accomplished by subjecting the clumps to centrifugal force, which causes them to break apart.

5. Foreign matter removal: Cyclone screens can be used to remove foreign matter, such as rock or metal fragments, from the material stream by separating foreign matter from the desired material by centrifugal force.

The material enters the cyclone screener from the upstream feeding device, and the feeding screw conveys the product to the screening chamber, where centrifugal motion is used to make the product pass through the screen. Screen-sized particles fall, while oversized particles, such as contaminants and agglomerates, are continuously discharged into an oversized product container. A baffle at the end of the screening chamber prevents on-spec material from entering oversized product containers. The screen material mounted on the ring is free to vibrate and thus cleans itself.

Can sieve 80-500 mesh ultrafine powder

It is suitable for sieving ultra-fine powder, low density (light specific gravity), slight humidity, easy to stick to sticky powder or materials with electrostatic reaction.

Remove foreign bodies, break up lumps

The screen is impacted by the cyclone, and has the functions of free shaking, automatic cleaning and crushing of bulk materials, and high screening efficiency.

Screening rate up to 85-95%

The screening efficiency can reach 85-95%, and the residue on the screen is basically 0 (which is difficult for ordinary vibrating screens).

Large output

It can be matched with single machine or multiple machines, and the output is 5-10 times or even higher than that of ordinary vibrating screen.

No noise

The noise level of the machine is kept below 80 decibels, which is lower than that produced by conventional machines, it also consumes less power without creating any additional vibration.

Cantilever design

Has a cantilever structure, so the screen can move freely without any resistance, and it is easy to clean and replace the screen quickly.

Various sizes

The screens are available in 4 different sizes, giving you the freedom to control the final product, There are a variety of screens to choose from.

Dust-free operation

The compact and airtight design makes it ideal for dust-free operation and the highest level of hygiene without any leakage.

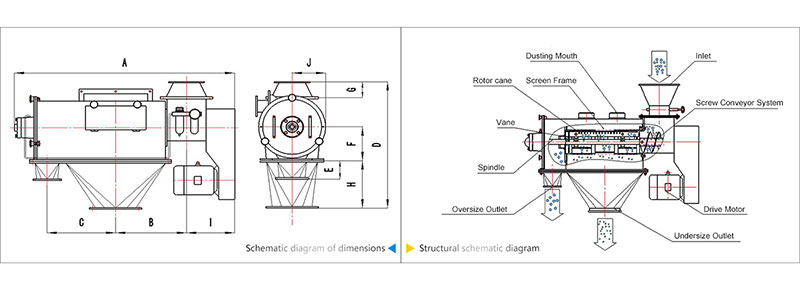

| Model | A | B | C | D | E | F | G | H | I | J |

| WQS18-65 | 1430 | 460 | 420 | 1005 | 135 | 230 | 250 | 330 | 340 | 210 |

| WQS30-100 | 1845 | 655 | 766 | 1240 | 320 | 285 | 300 | 350 | 380 | 290 |

| WQS50-130 | 2230 | 870 | 790 | 1775 | 280 | 515 | 150 | 660 | 400 | 485 |

| Model | Material | Power | Application |

| WQS18-65 | Q235A | 2.2KW | Screening below 500 mesh |

| SUS304 | |||

| WQS30-100 | Q235A | 4KW | |

| SUS304 | |||

| WQS50-130 | Q235A | 5.5KW | |

| SUS304 |

The structure of a cyclone screener consists of a cylindrical chamber with a tangential inlet and a central outlet. The chamber is typically lined with a wear-resistant material to enhance durability. The chamber may also be equipped with various internal components, such as vortex find ers , baffles, or cones, to improve separation efficiency and reduce turbulence.

In addition to the basic structure, there are several options or features that can be added to a cyclone screener to enhance its performance, including:

1. Material of construction: Cyclone screeners can be constructed from a variety of materials, including carbon steel, stainless steel, or ceramic, depending on the specific application requirements.

2. Diameter and height: The diameter and height of the cyclone screener can be customized to achieve the desired separation efficiency and throughput rate.

3. Inlet and outlet configurations: The inlet and outlet configurations of the cyclone screener can be customized to fit the specific process requirements, including angle, size, and location.

4. Screen: This series offers a variety of durable screening media options to meet specific application needs. These include: Nylon Mesh (offering high throughput and a variety of mesh sizes down to 30µ), Steel Mesh (for applications requiring metal detectable screen media), Wedge Wire (heavy duty for grinding inspection screening applications "Slotted" type metal screen), specialty polymers (it is similar to nylon screen, but uses a special polymer that can resist high temperatures, corrosive products, and static electricity.)

After sieving of 120-180 mesh light calcium, 300 mesh heavy calcium, 400 mesh active calcium, 300 mesh hawthorn powder, 320-500 mesh zinc powder, 500 mesh iron oxide black and other materials, a good screening effect was obtained. It is obtained that the hourly output per square meter of screen mesh area is about one ton, and the screening accuracy is measured to be above 95%, and the air dust content is less than 10mg/m3.

| Material | Typical Capacity | Material | Typical Capacity |

| COCOA POWDER | 1-70 TPH | CALCIUM STEARATE | 1-30TPH |

| FISH MEAL | 1-40 TPH | EXPANDED SILICA | 0.5-6 TPH |

| FLOUR | 1-60 TPH | HYDRATED ALUMINA | 1-30 TPH |

| GROUND COFFEE | 1-30 TPH | IRON OXIDE | 1-40 TPH |

| LACTOSE | 5-300 GPM | LATEX | 5-200 GPM |

| (20-1850 LPM) | (20-900 LPM) | ||

| MILK POWDER | 1-30 TPH | PAPER FIBER | 5-400 GPM |

| NON-DAIRY CREAMER | 1-50 TPH | (20-1800 LPM) | |

| SPICES | 1-40 TPH | PIGMENTS | 1-40 TPH |

| STARCH | 1-50 TPH | POLYMER BEADS | 1-250 GPM(20-1150 LPM) |

| SUGAR | 1-120 TPH | ||

| TOFU | 5-200 GPM | POWDER COATINGS | 1-30 TPH |

| (20-900 LPM) | TiO2 SLURRY | 5-250 GPM(20-1150 LPM) | |

| DISTILLERY SPENT GRAIN | 10-150 GPM |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.