The dust in the gas is separated by centrifugal force and is often used for dust removal of coarse particle materials.

![]()

![]()

![]()

Price:$800.00-$2,509.00/Set

Consult now and enjoy a 10% discount

Exhaust volume:6900-66900m³/h

Filter wind speed:1.2-2.0m/min

Filter area:93-929m²

Filter bag:96-960PCS

Power:1470-1770kw

Insulation layer area:26.5-175m²

Application: Cyclone dust collectors are widely used in coal mines, cement industry, wood processing, mining, metallurgy, food processing and other fields.

Commitment:

Cyclone dust collector, also called cyclone separator, is a commonly used dust collector. It is mainly used for dust recovery and collection of high-concentration waste gas. It is widely used in convection drying and drying systems. Under normal circumstances, theoretically The cyclone separator can capture powders of more than 5μmm, and the separation efficiency can reach more than 90%. It is the most economical solution to solve various dust problems. It can be used alone, or with bag filter components. Cleaner to use.

Cyclone dust collector is suitable for processing particles with larger particle sizes, such as dust, coal dust, wood chips, etc. It is one of the dust removal equipment commonly used in many industrial production processes. In the design of a cyclone dust collector, factors such as the gas flow rate, the size and shape of the cyclone tube, and the structural materials of the dust collector need to be considered to ensure its effective operation and efficient dust collection.

Works in a unique way by generating a high-speed rotating airflow, the air moves in a curved manner, starting from the very top of the cyclone and ending at the bottom, during this process, large particles of dust fall to the bottom of the cyclone, easily Cleared. The efficiency of the cyclone increases with decreasing gas density and decreasing outlet diameter. The main functions of the cyclone dust collector are as follows:

1. Very effective for high dust load and high temperature

2. Contribute to product recycling purposes

3. It is an economical solution to different dust removal problems

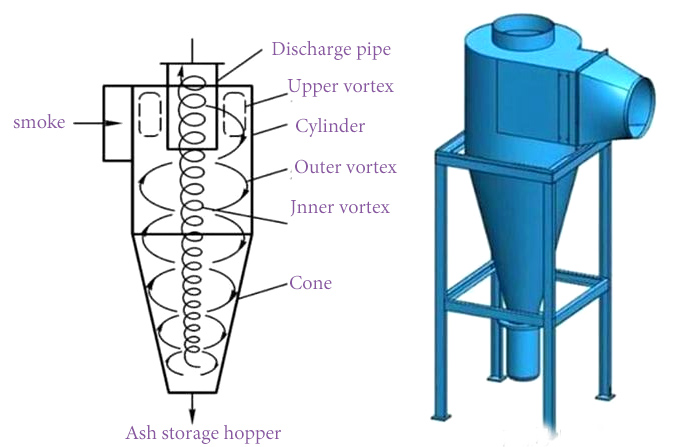

Cyclone dust collector is a process of separating particulate pollutants from the gas by using the centrifugal force generated by the rotating dust-laden airflow. The dust-laden gas enters the dust collector tangentially, and performs continuous rotating motion in the cyclone dust collector, so that the particles get larger The centrifugal force is thrown onto the wall of the container, collides and falls, and the dust particles slide along the wall of the container into the ash hopper at the bottom, and the outer cyclone flow turns into an upward reverse flow at the center of the bottom, and is then discharged through the exhaust pipe.

Good dust removal effect

It can capture powders above 5μmm, and the separation efficiency can reach more than 90%.

High temperature resistance

It can withstand high temperature of 600 ℃. If special high temperature resistant materials are used, it can also withstand higher temperatures.

Strong dust removal performance

After the dust collector is equipped with a wear-resistant lining, it can be used to purify the flue gas containing high abrasive dust.

Have recyclable

It can be dry cleaned, which is beneficial to the recovery of valuable dust.

Additional dust collection capacity

Connect the cyclone to the dust collector to form an extremely powerful two-step dust collection system, increasing the dust collection capacity to 99.99%.

Easy to use

The large-sized dust bucket can handle a large amount of dust, and the dust bucket is also equipped with casters to make dust removal easier.

| Model | Exhaust volume m3/h | Filter wind speed m/min | Filter area m2 |

Filter bag PCS |

Power kw | Insulation layer area m2 |

| DER32-3 | 6900 | 1.2-2.0 | 93 | 96 | 1470-1770 | 26.5 |

| DER32-4 | 8930 | 124 | 128 | 34 | ||

| DER32-5 | 11160 | 155 | 160 | 41 | ||

| DER32-6 | 13390 | 186 | 192 | 48.5 | ||

| DER64-4 | 17800 | 248 | 256 | 70 | ||

| DER64-5 | 22300 | 310 | 320 | 94 | ||

| DER64-6 | 26700 | 372 | 384 | 118 | ||

| DER64-7 | 31200 | 434 | 448 | 142 | ||

| DER64-8 | 35700 | 496 | 512 | 166 | ||

| DER96-4 | 26800 | 372 | 384 | 110 | ||

| DER96-5 | 33400 | 465 | 480 | 120 | ||

| DER96-6 | 40100 | 557 | 576 | 130 | ||

| DER96-7 | 46800 | 650 | 672 | 140 | ||

| DER96-8 | 53510 | 744 | 768 | 150 | ||

| DER96-9 | 60100 | 836 | 864 | 160 | ||

| DER96-2*5 | 66900 | 929 | 960 | 175 |

The cyclone dust collector is composed of four parts: exhaust pipe, intake pipe, cylinder and cone. The dust enters the dust collector from the inlet with the airflow, and rotates along the wall from top to bottom (this airflow is called the outer vortex), and the outer vortex reaches the bottom of the cone and then rotates up along the axis (this is called the inner vortex), and finally discharged from the discharge pipe. The inner and outer eddy currents rotate in the same direction. During the rotating motion, the dust particles move to the outer wall under the action of inertial centrifugal force, and finally the dust particles fall into the ash hopper along the wall surface under the combined action of airflow and gravity.

Cyclone dust collectors are suitable for capturing dry, non-fibrous granular dust. Because of its strong habit, it is widely used in coal mining, wood processing, mining and metallurgy, food, building materials, chemicals, cement and other industries.

The following are some specific applications of cyclone dust collectors:

Coal mining industry: In coal mine production, dust removal of coal dust and coal gangue is required to protect the health of workers.

Cement industry: Used for dust removal on coal mills, clinker mills and other equipment in the cement production process.

Wood processing: handle dust removal of solid particles such as wood chips and wood powder, keep the production workshop clean, and prevent safety issues such as dust explosions.

Mining and metallurgical industry: Used to treat dust generated during metal ore processing and reduce environmental pollution.

Food processing: In grain processing, flour production, etc., dust collectors can handle dust and impurities.

Chemical industry: Used to treat solid particles produced in chemical production, purify gas flows, and protect production equipment and the environment.

Building materials industry: In processes such as stone processing and ceramic production, dust collectors can handle solid particles such as stone powder and ceramic tile powder.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.