A cyclone screener is a rotary screen designed to separate particles of different sizes into two product streams and remove impurities, so how does a cyclone screener work? This article will introduce you to the structure principle of cyclone screener.

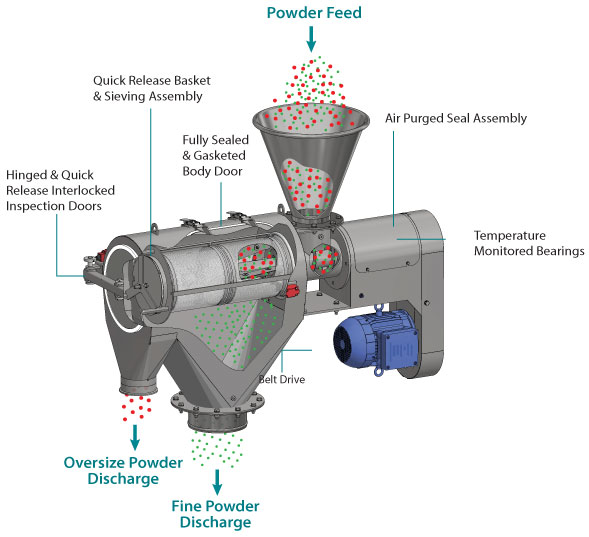

Cyclone screener is mainly composed of vibrating motor, base, screen, feeding and discharging propulsion device, etc.

Motor: The motor drives and rotates at approximately 500RPM, providing vibration-free performance and high throughput with little or no product degradation.

Screens: Available in a variety of pore sizes to meet a variety of screening applications throughout the processing and packaging industries.

Hinged access doors on the side of the housing allow for visual inspection, and the shaft end housing with ventilation holes and external bearings can be removed with a screw knob to replace, inspect or clean screens and paddles.

Inlet and outfeed propelling device: the rotating paddle throws the material to and through the hole of the screen cylinder, and sprays the oversized particles to the discharge port through the downstream end of the screen cylinder.

The material fed into the static horizontal screen drum by the auger is pushed onto the screen by the rotating paddle, the particles with suitable size enter the discharge groove through the screen hole, and the oversized material enters the discharge port through the cylinder screw.

The cyclone screener is used to separate particles of two different sizes. The centrifugal force generated by the blades is also very suitable for breaking agglomerated and agglomerated powders. It can be sieved to 530 mesh, and the sieving penetration rate can reach 85-95%, and the residue on the sieve The material is 0 (difficult to be achieved by ordinary vibrating screens), the screen areas are 3.5 square meters and 6 square meters respectively, and the processing capacity is 5-10 times that of vibrating screens.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.