Suitable for ultra-fine powder with many fibers, high viscosity, light specific gravity, easy to generate static electricity and block the mesh.

![]()

![]()

Price:$900.00-$5,700.00/Set

Consult now and enjoy a 10% discount

Mesh size: 80-530 mesh

Screen cylinder perforation size: 0.15-10mm

Processing capacity: 1-15 t/h

Material: carbon steel or stainless steel

Power: 3-15KW

Application: Suitable for screening fine powder, such as flour, graphite powder, rubber powder, magnesium oxide, perlite powder, iron powder, epoxy resin powder, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

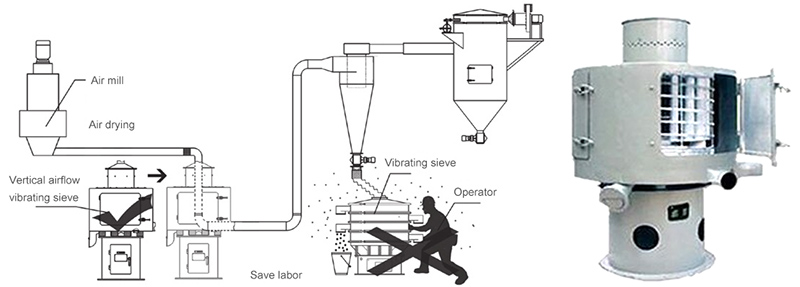

Vertical airflow vibrating sieve uses airflow to atomize raw materials into monomers to solve the problem of fine powder screening with adhesion, high static electricity and easy agglomeration. It can improve the purity of the product and solve the problem of vibro sifter, linear vibrating screen and other equipment in screening fine powder. Problems such as flying dust often occur.

Vertical airflow vibrating sieve screens are as fine as 80-530 mesh, with a screen penetration rate of 85-95%. It does not stick to the mesh, does not block the mesh, and has a fineness. The output is 5-10 times or higher than that of ordinary vibrating screens.

The vertical airflow vibrating sieve performs several functions in particle separation and classification. Here are the main functions of the vertical airflow vibrating sieve:

1.Particle separation: The primary function of the vertical airflow vibrating sieve is to separate particles based on their size and density. The sieve uses the combination of vertical airflow and gravity to lift and suspend particles in the air, allowing for effective separation of particles with different sizes and densities.

2.Scalping: The vertical airflow vibrating sieve can be used for scalping, which is the removal of oversized or undersized particles from the material feed. By adjusting the vibration intensity and airflow speed, the sieve can effectively remove particles that do not meet the desired size criteria, ensuring a more uniform and consistent particle size distribution.

3.Dedusting: The sieve can also function as a dedusting device by removing fine particles or dust from the material. The vertical airflow lifts the fine particles, allowing them to be carried away by the airflow, while the larger particles are retained on the sieve decks. This helps in reducing dust emissions and improving the overall cleanliness of the material.

Vertical airflow vibrating sieve uses air as the carrier and kinetic energy as the work principle. Using the characteristics of the powder's good fluidity, small and light weight, and easy to float, the material is mixed with the air through the negative pressure airflow, and then enters the screen fan wheel. In the middle, enough centrifugal force is exerted through the blades of the wind rotor, and it is sprayed to the barrel-shaped screen and collected through the volute.

Efficient screening

Adopting the air flow separation method, the screen penetration rate can reach 85-95%, the screen does not stick to the screen, does not block the screen, the screen is fine, there is no super mixing phenomenon, and the screen residue is 0 (difficult to achieve with ordinary vibrating screens).

Large output

The product is 5-10 times that of ordinary vibrating sieves. For example, vertical airflow vibrating sieve can screen 100 grams of samples, while vibrating sieve can only screen 6kg samples.

No clogging and clogging

Compared with traditional mechanical screening equipment, vertical airflow vibrating sieve can effectively handle sticky, moist or easy-to-agglomerate materials, reducing the risk of screen clogging.

Low energy consumption and low noise

High-efficiency fans or blowers are usually used to provide airflow, which can produce sufficient airflow force with low energy consumption. At the same time, the noise during the vibrating screening process is also low, reducing interference to the working environment and operators.

Flexibility and adjustability

By adjusting the air flow speed, vibration frequency and screen aperture, screening and classification of different materials and particle size ranges can be achieved, improving the flexibility and adaptability of the equipment.

Environmental protection and health

Dust and particles generated during the screening process can be effectively controlled and processed through the collection system, reducing environmental pollution.

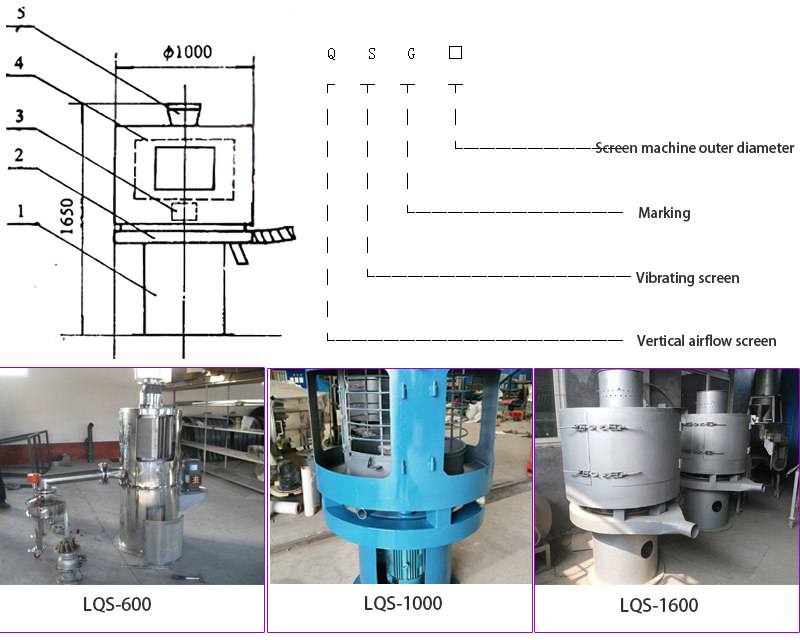

| Item | LQS-600 | LQS-1000 | LQS-1600 |

| Air flow rate | 240-1100 | 300-2500 | 460-4900 |

| Sieve size | any replacement of 80-600 meshes | ||

| Grain size | 40 mesh to fine | ||

| Screen machine power | 3kw | 5.5kw | 15kw |

| Speed of mainshaft | 450-1450 | ||

| Outside diameter of screen machine | Φ600 | Φ1000 | Φ1600 |

| Full height | 1150mm | 1730mm | 2300mm |

Horizontal airflow vibrating sieve and vertical air flow vibrating sieve have their own characteristics in structural design, working principle and application field. Their differences are introduced in detail below.

| Types | Horizontal Airflow Vibrating Sieve | Vertical Airflow Vibrating Sieve |

|

|

|

| Structure | The screen body is arranged horizontally, and the feed port and the discharge port are located on the same horizontal plane. Suitable for production environments with relatively spacious space. | The screen body is arranged vertically, with the feed port at the top and the discharge port at the bottom.Suitable for production environments with relatively compact space. |

| Working principle | The material is pushed by the air flow in the screen and passes through the screen in the horizontal direction to complete the screening process. | The material is affected by the air flow and gravity in the screen and passes through the screen in the vertical direction to complete the screening process. |

| Advantages | High screening accuracy, suitable for screening of fine powder materials, such as flour, chemical powder, etc. | High screening efficiency, small footprint, suitable for screening of small particles and lightweight materials, such as Chinese medicine powder, metal powder, etc. |

| Application areas | It is suitable for industries such as chemical, food, and medicine, especially where high-precision screening is required. | It is suitable for industries such as metallurgy, building materials, and pharmaceuticals, especially where space is limited and efficient screening is required. |

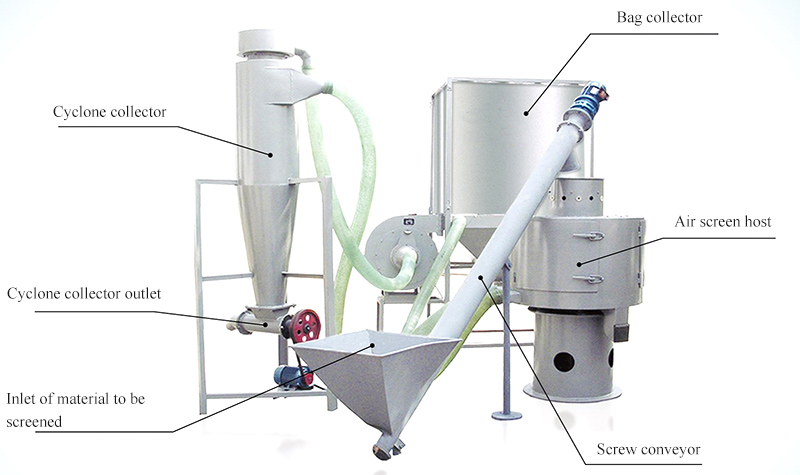

Vertical airflow vibrating sieve, cyclone discharger and bag dust removal device form a closed circuit screening and dust removal system. The main machine is a vertical airflow sieve. The airtight casing of the upper screen body is equipped with a vertical circular cylindrical screen. The inner side of the screen is equipped with a circular wind wheel. Sieve.

The vertical airflow vibrating sieve is equipped with a feeding hopper and a coarse screen just above the casing. There is a specially designed slag discharge port at the lower part of the air duct. The motor and the main shaft are connected by a belt; the wind wheel and the lower opening of the feeding hopper form a partition gap. The cyclone separation discharger and the bag dust removal device are connected by a positive pressure induced draft fan through a plastic corrugated hose.

Vertical airflow vibrating sieve has flexible configurations and can be customized according to different material characteristics and production requirements.

1. Screen material and mesh number

Material: stainless steel, nylon, polyester, etc., can be selected according to the corrosiveness and temperature of the material.

Mesh number: from dozens of mesh to thousands of mesh, can be selected according to the screening accuracy requirements.

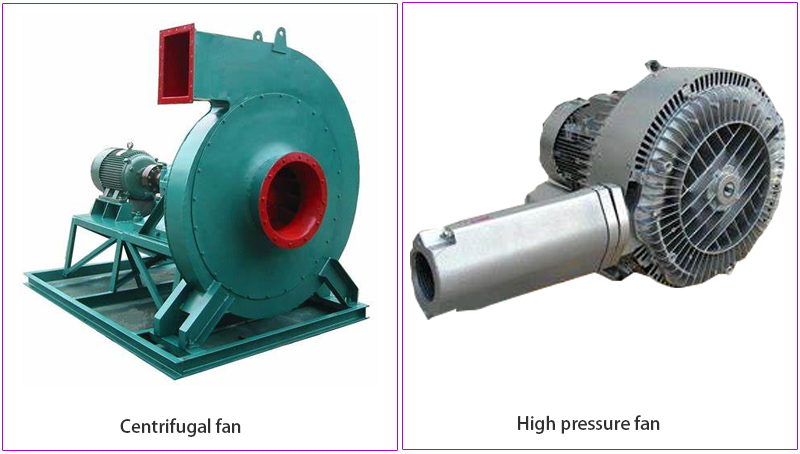

2. Fan type and air volume

Fan type: high-pressure fan, centrifugal fan, etc., selected according to the material characteristics.

Air volume: adjustable, affecting the suspension height and screening efficiency of the material.

3. Dust removal device

Bag dust removal: suitable for the collection of fine dust.

Cyclone dust removal: suitable for the collection of dust with larger particles.

4. Feeding method

Manual feeding: simple and easy to operate, suitable for small batch production.

Automatic feeding: improve production efficiency, suitable for large batch production.

5. Discharging method

Manual discharging: suitable for small batch production.

Pneumatic discharging: high degree of automation, suitable for large batch production.

Vertical airflow vibrating sieve is suitable for screening fine powder materials that are easy to adhere, small in particle size, light in weight, and easy to suspend. It can continuously screen powder materials with a fineness range of 80-500 mesh.

The screening efficiency is above 95%, and the dust content in the air is less than 10mg/m3. It is widely used in chemical, pharmaceutical, food, metallurgy, building materials and other industries, and is suitable for screening the following types of powders:

Chemical powder: light calcium, heavy calcium, active calcium, resin powder, graphite powder, black iron oxide, red iron oxide, magnesium oxide, talcum powder, carbon black, etc.

Medical powder: Chinese medicine powder, western medicine powder, health care powder, etc.

Food powder: starch, milk powder, flour, powdered sugar, etc.

Metal powder: aluminum powder, zinc powder, copper powder, etc.

Non-metallic mineral powder: diatomaceous earth, talcum powder, quartz powder, etc.

Other powders: pigments, dyes, plastic powder, etc.

Among our customers, they screen light calcium powder, heavy calcium powder, active calcium, slag powder, starch, zinc powder, fly ash, black iron oxide, red iron oxide, Chinese medicine powder, quartz powder, flour, wood powder, mica powder and other powders. We are equipped with different sieve apertures, and finally we can successfully complete the screening of these materials. The following are some detailed information and scenarios for the screening of different powders.

| Product | Way of working | Mesh size (mesh) |

LQS-1000 (kg/h) |

LQS-1500 (kg/h) |

| Lght calcium powder | Dry | 120-180 | 600-1000 | 1000-2000 |

| Heavy calcium powder | 400 | |||

| Active calcium | 500 | |||

| Slag powder | 300 | |||

| Starch | 300 | |||

| Zinc powder | 325 | |||

| Ffly ash | 120-200 | |||

| Iron oxide black | 500 | |||

| Iron oxide red | 500 | |||

| Chinese medicine powder | 120-160 | |||

| Quartz powder | 180-270 | 2000-3000 | ||

| Flour | 100-180 | 200-300 | 500-1000 | |

| Wood flour | 100-300 | 200-300 | 500-1000 | |

| Mica powder | 300-400 | 200-300 | 500-1000 |

As the source manufacturer of vertical air flow vibrating screen, we have a history of more than ten years. We provide vertical air flow vibrating screen with a screen fineness of 80-530 mesh, a screen penetration rate of 85-95%, and a processing capacity of 15 tons per hour. It is suitable for screening various powders with strong adhesion and fine powder quality. It is made of stainless steel and carbon steel and is suitable for different industries. We promise 5-day delivery/30-day return. In addition, we support customized needs. If you need it, please feel free to contact us!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.