Horizontal airflow vibrating sieve mainly uses the airflow to sieve the materials. It can drive the fine particles of materials through the screen by the airflow, and use the characteristics of the powder particles to be small and light, easy to float, and have good fluidity. Fully diffused into the airflow, the powder is no longer agglomerated, but passes through the sieve with the airflow in sequence as a single particle, so the horizontal airflow vibrating sieve has high sieving accuracy, and can sieve fine powder within 80-500 mesh, with high sieving efficiency. It can reach 85-95%, the residue on the screen is basically 0 (it is difficult for ordinary vibrating sieves), and the product is 5-10 times that of ordinary vibrating sieves.

Horizontal airflow vibrating sieve has an automatic feeding function. Its internal feeding function also uses the flow of air flow. When feeding, the material can be brought to the feeding port by the power generated by the high-speed flow of the air flow. The use of air flow to screen materials can screen fine materials to a large extent, so that the use of air flow to screen materials is not easy to block the screen.

Horizontal airflow vibrating sieve is suitable for the screening and classification of various powder materials of 80-500 mesh. It has high screening efficiency, large output, automatic feeding and discharging, continuous operation, and good dust resistance,It has the following two functions:

1. Screening function

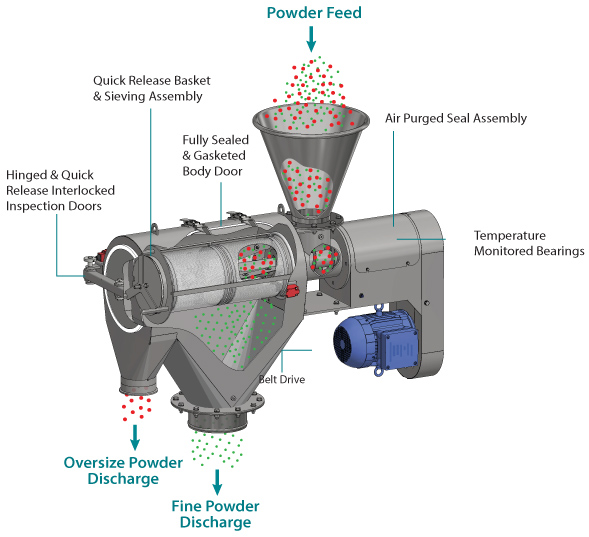

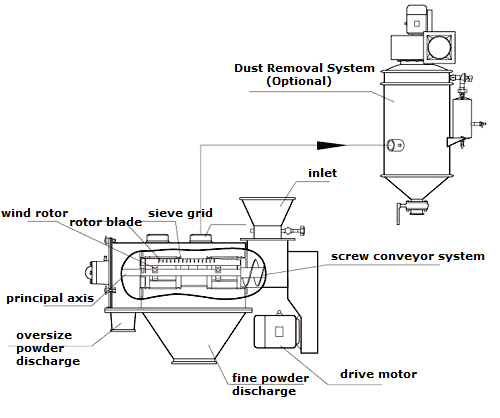

A layer of screen is placed in the horizontal screen box of the Horizontal airflow vibrating sieve. The wind power generated by the wind rotor blades in the screen box will blow the powder material into it, so that it hits the screen and is screened, because it can only be installed One layer of sieve can only be used for simple sieving or impurity removal, but the sieve of any mesh within the sieving mesh can be replaced as required.

2. Crushing function

Horizontal airflow vibrating sieve has a simple screw conveying system structure, and the wind rotor blades in the screen box are constantly rotating with strong wind, which has a crushing effect on false agglomerated materials.

After the material passes through the screw conveying system, it is mixed with the airflow and atomized into the mesh cylinder of the horizontal airflow vibrating sieve. The material is discharged from the material discharge port, and the material that cannot pass through the mesh is discharged from the coarse material discharge port along the wall of the mesh cylinder.

1. Through screening and separation, the screening efficiency can reach 85-95%, and the residue on the screen is basically 0 (which is difficult to achieve by ordinary vibrating screens).

2. It can process powder or granules from a few kilograms per hour to more than 90 tons, and the output is 5-10 times or higher than that of ordinary vibrating screens.

3. The screen is cleaned by a cyclone, which automatically cleans the screen and has the function of re-crushing the agglomerated material to prevent the screen from being blocked.

4. 30-second screen change for inspection and cleaning through an easy-to-remove screen.

5. The cantilever shaft design ensures that there are no oversized bearings or seals, and the maintenance cost is low.

| Model | Material | Power | Application |

| WQS18-65 | Q235A | 2.2KW | Screening below 500 mesh |

| SUW304 | |||

| WQS30-100 | Q235A | 4KW | |

| SUW304 | |||

| WQS50-130 | Q235A | 5.5KW | |

| SUW304 |

Horizontal airflow vibrating sieve has been successfully applied to 120-180 mesh light calcium, 300 mesh heavy calcium, 400 mesh active calcium, 300 mesh hawthorn powder, 320-500 mesh zinc powder, 500 mesh iron oxide black and other materials, a good screening effect was obtained. It is obtained that the hourly output per square meter of screen mesh area is about one ton, and the screening accuracy is measured to be above 95%, and the air dust content is less than 10mg/m3.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.