Works on the principle of centrifugal force and is used to transport bulk materials vertically or inclined

![]()

![]()

![]()

Price:$500.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Delivery capacity: 5.4-365 cubic/hour

Lifting height: 40 meters

Equipment material: carbon steel, stainless steel

Material temperature: ≤250℃

Bucket capacity: 5.2~10L

Bucket speed: 1.25m/s

Motor power: 5.5~7.5KW

Application: It has a wide range of application precedents in the screening and classification of granular and powdery materials in chemical, food, metallurgy, mining, building materials, grain, abrasives, chemical fertilizers, and coal industries.

Applied materials: cement, raw meal, fly ash, flour, talcum powder, phosphate rock powder

Centrifugal bucket conveyor, also known as a centrifugal discharge elevator or centrifugal bucket elevator, is a type of bucket conveyor used for vertical or inclined transportation of bulk materials. It operates based on the principle of centrifugal force.

Centrifugal bucket conveyors are commonly used in industries such as agriculture, mining, and food processing. They are suitable for handling granular or powdered materials such as grains, seeds, fertilizers, and various bulk solids. The design of the buckets and the speed of rotation can be adjusted to accommodate different material properties and desired conveying capacities.

A centrifugal bucket elevator operates based on the principle of centrifugal force. Here's a step-by-step explanation of how it works:

Material Loading: The centrifugal bucket elevator begins with the loading of bulk material into the buckets at the bottom end of the elevator. The material is fed into the buckets either by scooping it directly or by means of a feed conveyor that deposits the material into the buckets.

Belt/Chain Movement: Once the buckets are loaded, the continuous loop belt or chain starts moving. The belt or chain is driven by a motorized pulley or sprocket at the top end of the elevator. As the belt/chain moves, it carries the buckets along with it in a circular motion.

Centrifugal Force Generation: The belt/chain movement causes the loaded buckets to move around the top pulley or sprocket. The circular motion generates centrifugal force, which pushes the material outwards against the walls of the buckets. This force keeps the material in the buckets as they move upwards.

Material Discharge: As the buckets reach the top end of the elevator, they pass over the top pulley or sprocket. At this point, the centrifugal force is at its maximum. The material is forced out of the buckets due to the high centrifugal force, and it is directed into the discharge chute or spout.

High conveying capacity

It can lift and convey materials at a high speed, can handle a large amount of materials, and is suitable for high-yield and large-capacity application scenarios.

Wide range of applications

It is suitable for processing many types of materials, including granular, powdery and granular materials, such as coal, ore, grain, fertilizer, etc.

Reduce material accumulation

Due to the centrifugal force, the centrifugal bucket elevator can better disperse the materials when unloading, reduce the accumulation and clogging of materials, and improve the efficiency and stability of unloading.

Smaller footprint

The structure is relatively compact and the space occupied is relatively small, making it suitable for vertical transportation of materials in a limited space.

Lower energy consumption

Centrifugal bucket elevators are usually driven by electric motors. Compared with other types of elevators, their energy consumption is lower, which can save energy and reduce operating costs.

High reliability

The centrifugal bucket elevator adopts a solid structure and reliable transmission system, which can operate stably and withstand large workloads, and has high reliability and durability.

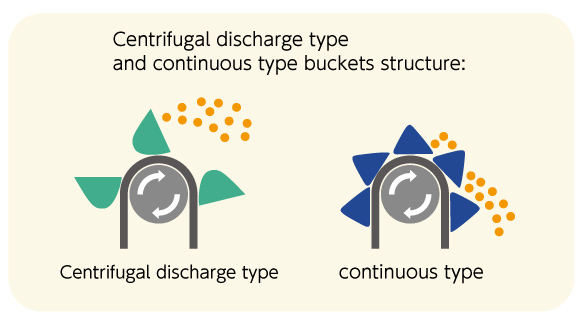

The main difference between continuous and centrifugal bucket elevators lies in the way they handle and discharge the material.Here are some additional differences between continuous and centrifugal bucket elevators:

1.Discharge Mechanism: Continuous bucket elevators use a controlled discharge mechanism, such as a gravity chute or a rotary valve, to regulate the flow of material at the top or bottom of the elevator. Centrifugal bucket elevators, on the other hand, rely on centrifugal force to discharge the material at the top of the elevator.

2.Conveying Capacity: Centrifugal bucket elevators generally have a higher conveying capacity compared to continuous bucket elevators. The higher speed and larger bucket spacing allow for faster and more efficient material handling.

3.Application: Continuous bucket elevators are suitable for handling fragile or delicate materials that require gentle handling and minimal impact. Centrifugal bucket elevators are better suited for robust materials that can withstand the impact and centrifugal forces generated during operation.

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

Centrifugal bucket elevators are widely used in vertical conveying of bulk materials in various industries. Here are some common applications for centrifugal bucket elevators:

1. Agriculture and grain transportation: used to transport grain, seeds and other agricultural products. They are used in grain storage facilities, flour mills, feed mills and seed mills to efficiently transport bulk materials such as wheat, corn, rice, soybeans and barley. Centrifugal elevators are ideal for handling these produce because of their ability to handle high volumes and discharge material quickly.

2. Mining and minerals: used to process various types of bulk materials such as coal, ore, limestone, gypsum and other minerals. They are commonly used in mines, quarries and concentrators for the vertical transport of these materials. Centrifugal lifts are favored for their robust construction and ability to handle abrasive and heavy materials.

3. Cement and building materials: used in cement plants and building material production facilities. They are used for vertical conveying of materials such as cement, clinker, sand, gravel and aggregates. Centrifugal elevators facilitate the production of concrete, mortar, and other construction materials by efficiently transporting these materials to the desired height.

4. Chemical and chemical fertilizer industry: suitable for conveying bulk materials in chemical and chemical fertilizer industries. They are used in fertilizer production plants, chemical processing facilities and blending operations to vertically convey materials such as granular fertilizers, urea, ammonium nitrate and various compounds. The high-speed discharge of the centrifugal elevator ensures efficient movement of these materials throughout the production process.

5. Food processing: used in the food processing industry to vertically transport food such as grains, beans, nuts, seeds and spices. They are used in grain processing plants, snack food manufacturing and other food production facilities where efficient and hygienic handling of bulk materials is required.

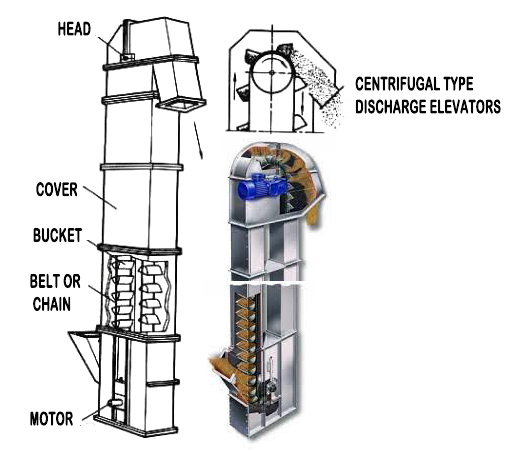

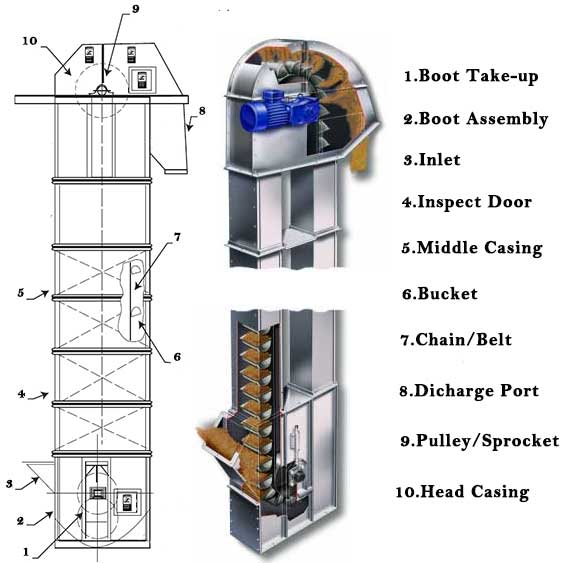

Here are some key features and components of a centrifugal bucket elevator:

Buckets: Similar to other bucket elevators, centrifugal bucket elevators have buckets attached to a belt or chain. The buckets are specifically designed to scoop up the material at the bottom of the elevator and carry it to the top for discharge. The shape, size, and spacing of the buckets depend on the characteristics of the material being handled.

Belt or Chain: The buckets are mounted on a continuous loop belt or chain, which circulates around a series of pulleys or sprockets. The belt or chain is driven by a motor, which powers the movement of the buckets, lifting the material to the desired height.

Discharge Chute: At the top end of the elevator, a discharge chute or spout is positioned to direct the material as it is discharged from the buckets. The high speed and centrifugal force generated by the elevator result in a controlled and rapid discharge of the material into the desired receiving equipment or storage location.

Drive System: The drive system of a centrifugal bucket elevator consists of a motor, gearbox, and other components that provide the power to move the belt or chain. The motor is typically electrically powered and can be controlled to adjust the speed and direction of the elevator.

Supporting Structure: The supporting structure provides the framework for the elevator, ensuring stability and strength to handle the loads imposed by the material being conveyed. The structure includes vertical columns, horizontal beams, and other supporting elements that keep the elevator in place and properly aligned.

Determining the appropriate size and capacity for a centrifugal bucket elevator involves considering several factors. Here are the key steps involved in the sizing and capacity determination process:

1.Identify Material Characteristics: Start by understanding the properties of the material that will be handled by the bucket elevator. This includes factors such as bulk density, particle size distribution, flowability, abrasiveness, and temperature. These characteristics will affect the selection of bucket size, speed, and other design parameters.

2.Determine Required Capacity: Determine the desired or required capacity of the bucket elevator, which is typically expressed in terms of the material flow rate (e.g., tons per hour or cubic meters per hour). Consider factors such as production requirements, processing time, and desired throughput when determining the capacity.

3.Calculate Bucket Spacing and Speed: Bucket spacing refers to the distance between buckets on the belt or chain. The spacing should be selected based on the material size and flowability to ensure proper filling and discharge. The bucket speed is another critical parameter that affects the capacity. Higher speeds generally result in higher capacities, but they should be within the limits of material handling capabilities and safety considerations.

4.Select Bucket Size and Shape: Choose an appropriate bucket size and shape based on the material characteristics and required capacity. Consider factors such as bucket volume, depth, and shape to ensure efficient filling and discharge of the material.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.