It is a kind of equipment used to transport various bulk materials or granular materials in vertical direction.

![]()

![]()

Price:$500.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Type: belt type/chain type

Maximum size of material: 25-45mm

Lifting height: ≤35 meters

Bucket capacity: 0.5-23.5 L

Pitch of buckets:280-500mm

Bucket speed: 1.25-2m/s

Material:Carbon steel/Stainless Steel

Application: It is suitable for conveying various bulk materials, such as grains, cement, ore, fertilizer, chemical raw materials, etc. It is widely used in grain processing, metallurgy, chemical industry, construction and other industries.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Vertical bucket elevators are a type of conveyor system used to elevate bulk materials vertically. They consist of a series of buckets attached to a chain or belt that moves in a continuous loop, allowing materials to be lifted from one level to another. Vertical bucket elevators are commonly used in industries such as agriculture, mining, construction, and manufacturing for handling materials like grains, fertilizers, aggregates, and powders.

Vertical bucket elevators are usually used in conjunction with crushers, silos, mixers, packaging machines and other equipment to achieve vertical transportation and lifting of granular materials, providing efficient material transportation solutions for production lines, up to a height of 40 meters.

1. Vertical conveying: Bulk materials or granular materials are conveyed vertically from the bottom to the top or high places. This makes it easy to transport raw materials or finished products from one height to another during industrial production.

2. Automated production: Vertical bucket elevators can usually be integrated with other production equipment to realize automated production lines, improve production efficiency and reduce labor costs.

There are many types of vertical bucket elevators. The three common types of vertical bucket elevators include: Belt Type Bucket Elevator, Chain Bucket Elevator and Z Type Bucket Elevator.

Belt Type Bucket Elevator

It uses belts as a device for conveying and lifting bulk materials, and is suitable for various bulk materials, including grains, seeds, fertilizers, minerals, aggregates, powders and other free-flowing or non-free-flowing materials.

Chain Bucket Elevator

The chain is used as the driving mechanism to lift and transport bulk materials vertically or tiltedly. Ideal for heavy-duty industrial applications involving the handling of strong and abrasive materials such as ores, minerals, aggregates and other coarse-grained materials.

Lifting height: ≤20m

Lifting capacity: 5.4-72m³/h

Z Type Bucket Elevator

Used to convey bulk materials in a Z-shaped path, suitable for various bulk materials, including grains, seeds, potato chips, snacks and other fragile and fragile materials.

Discharge height: 1.5-12m

Feeding length:≤1.3m

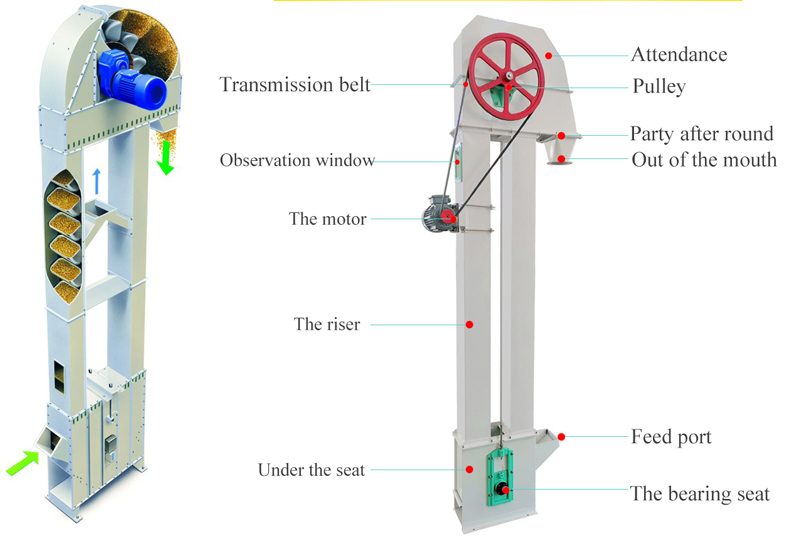

Vertical bucket elevator is mainly composed of hopper, traction belt (or chain), driving device casing and inlet and discharge ports. When working, the conveyed material is evenly fed from the feeding port. Driven by the driving roller, the hopper fixed on the conveyor belt scrapes the material and then rises together with the conveyor belt. When it rises to the top of the top driving roller, the hopper starts. Turn over, under the action of centrifugal force or gravity, the material is discharged from the discharge port and sent to the next process.

efficient material handling

Designed for the vertical transport of materials, making it an efficient way of moving bulk materials between different levels of the production line.

High capacity

Can handle bulky material over long distances, making it a suitable choice for high-volume applications with vertical heights of up to 40 meters or more.

Reduce product damage

Designed to minimize product damage during shipping, which helps maintain the quality of the material being shipped.

Low maintenance

Require less maintenance than other types of material handling equipment because they have fewer moving parts and are simpler in design.

Safety

Can be equipped with a variety of safety features including blast doors, fire suppression systems and monitoring systems to prevent overloading or other hazardous situations.

Customizable

Can be customized to meet the specific needs of a production line, including bucket size and capacity, elevator speed, and type of material being conveyed.

| Model | Feed size MM | Bucket | Height m | Lifting capacity (m³/h) | Weight | ||

| Distance mm | Width MM | Capacity L | |||||

| TB250 | 90 | 200 | 250 | 3 | 5-40 | 25 | According to the specific vertical bucket elevator order total drawing verification to determine |

| TB315 | 100 | 200 | 315 | 6 | 46 | ||

| TB400 | 110 | 250 | 400 | 12 | 75 | ||

| TB500 | 130 | 320 | 500 | 25 | 95 | ||

| TB630 | 150 | 400 | 630 | 50 | 148 | ||

Note: THE conveying capacity in the table is calculated according to the filling coefficient ψ-0.8 for reference only. |

|||||||

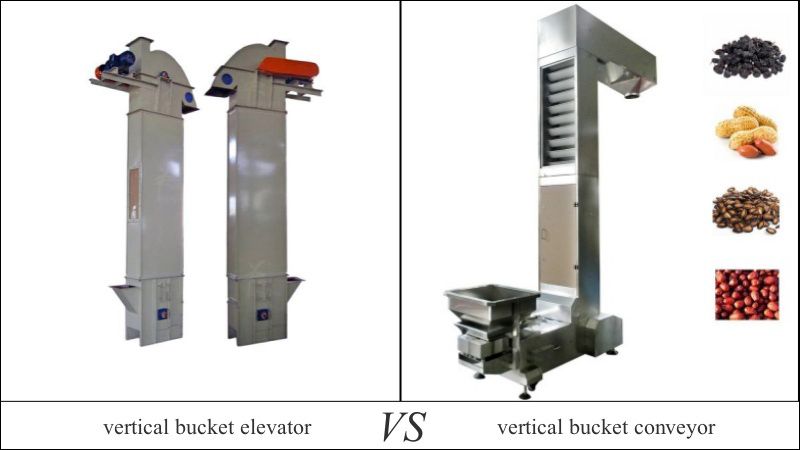

Different conveying directions: Vertical bucket conveyors are mainly used for long-distance conveying in horizontal and inclined directions, vertical bucket elevators are specially used for conveying in vertical directions, lifting materials from below to above.

Different applications: Vertical bucket conveyors are suitable for situations where materials need to be transported in a horizontal or inclined direction, such as factory production lines; vertical bucket elevators are often used in situations where materials need to be lifted vertically, such as warehousing facilities.

Run differently: the bucket of a vertical bucket conveyor runs on a horizontal or inclined conveyor line, transporting materials from one location to another; the bucket of a vertical bucket elevator runs in the vertical direction, lifting materials from below Go to the top to achieve the vertical lifting function.

Here's a quick comparison table:

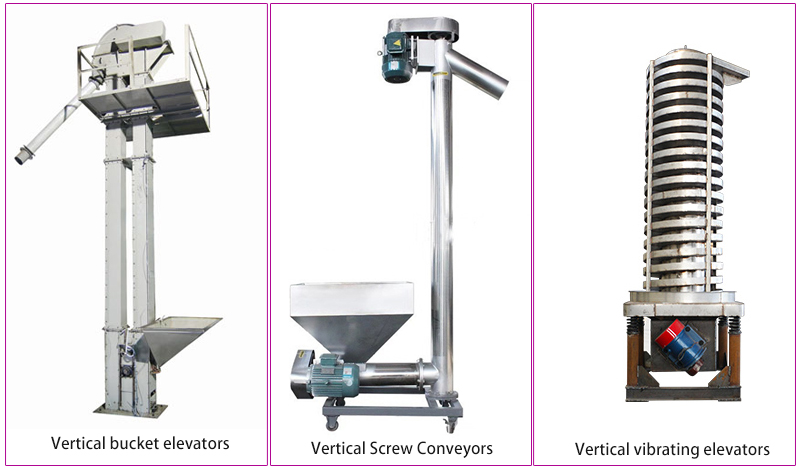

| Features | Vertical bucket elevators | Vertical Screw Conveyors | Vertical vibrating elevators |

| Applications | For vertical conveying of bulk materials such as grain, fertilizer, ore, etc. | For conveying bulk materials or powders | For conveying bulk materials |

| Efficiency | Highly efficient, suitable for vertical conveying | Moderate, depending on screw design | Moderate, depending on vibration mechanism |

| Transportation | Moderate to high, depending on size and design | Moderate, smaller diameter screw conveyors have lower conveying capacities | Moderate, depending on vibration frequency and amplitude |

| Height | High, up to tens of meters | Generally low, vertical height does not exceed 5 meters | Low, suitable for medium-height transportation, vertical height does not exceed 8 meters |

| Cost | Usually higher, as suitable for specific vertical conveying needs | Moderate, depending on screw mechanism and length | Moderate, depending on vibration mechanism and design |

Selection method:

If you need to transport a large amount of materials, have the highest requirements for sealing, and have a variety of types, you can choose a vertical bucket elevator.

If you need limited space and have high requirements, you can choose a vertical screw conveyor.

If you need to transport fine particles, choose a smaller target requirement, or need to cool down, you can use a vertical vibrating elevator.

The structure of a vertical bucket elevator typically consists of the following components:

Head Section: This section contains the head pulley, which is powered by a motor. The head section is responsible for lifting the buckets filled with material.

Boot Section: The boot section is located at the bottom of the elevator and houses the boot pulley or sprocket. This section is where the material is fed into the buckets.

Buckets: Buckets are attached to a belt or chain and are used to carry the material vertically.

Belt or Chain: The belt or chain runs around the head and boot pulleys and carries the buckets. The type of belt or chain used depends on the specific requirements of the application.

Casing: The elevator is enclosed by a casing to prevent spillage and provide safety. The casing also helps in maintaining a controlled environment for material transport.

Drive Unit: The drive unit consists of a motor, gearbox, and coupling, which provide the necessary power to drive the elevator.

Discharge Chute: At the top of the elevator, there is a discharge chute where the material is unloaded from the buckets.

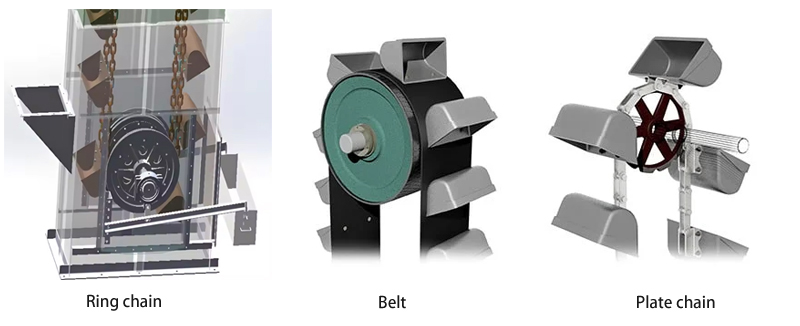

When choosing a conveying method for a vertical bucket elevator, you can usually consider ring chain, belt and plate chain. The differences between them are mainly reflected in the following aspects:

Ring chain: has high strength and wear resistance, suitable for heavy and high-strength material transportation, and has a long service life.

Belt: suitable for occasions where material requirements are not too strict, with lower maintenance costs and less noise.

Plate chain: has high wear resistance and stability, suitable for occasions with high material requirements, and has a long service life.

The vertical bucket elevator is suitable for lifting from a low place to a high place. After the supply material is put into the hopper through the vibrating table, the machine runs automatically and continuously to convey the product upward. Some common applications include:

1. Agriculture: Used to transport grain, seeds and other bulk materials between different stages of the production process.

2. Mining industry: It is used in the mining industry to transport coal, ore, minerals and other materials from underground mines to the surface.

3. Food processing: Used in food processing facilities to transport grain, flour, sugar and other food products between different stages of the production process.

4. Chemical processing: used in the chemical processing industry to transport materials such as fertilizers, plastics and other chemicals between different stages of the production process.

5. Construction: used in the construction industry to transport materials such as cement, sand and gravel between different levels of the construction site.

6. Power plants: used in power plants to transport coal, biomass and other materials from storage bins to boilers as fuel.

1. Grain processing plant: used to lift wheat from the ground to the top of the warehouse, the customer requires a lifting height of 20 meters and a conveying capacity of 30 tons per hour. We recommend a belt-type vertical bucket elevator.

2. Cement plant: In the cement production line, it is used to lift cement powder from the storage silo to the mixing equipment. The customer requires a lifting height of 25 meters and a conveying capacity of 50 tons per hour. We recommend a TH ring vertical bucket elevator

3. Fertilizer production enterprise: In the fertilizer production line, it lifts granular fertilizer from the production line to the packaging area. The customer requires a lifting height of 15 meters and a conveying capacity of 20 tons per hour. We recommend a NE series plate chain bucket elevator

These cases show the diverse applications and efficient performance of vertical bucket elevators in different industrial fields.

Xinxiang Dahan vertical bucket elevator manufacturer is a company specializing in manufacturing vertical bucket elevators. They are committed to providing efficient and reliable hoist solutions that are widely used in various industries. Their products feature high-quality design and manufacturing processes and comply with relevant quality standards and safety requirements. Through their hoist equipment, customers are able to achieve efficient material transportation and handling, improving production efficiency.

WhatsApp:+86 15236742901

Address:China,Yanjin county forest park gate to the west 1000 meters north road.