The unloading methods of the bucket elevator can be divided into three types: centrifugal type, gravity type and mixed type.

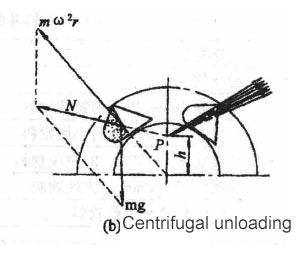

Use centrifugal force to throw the material out of the discharge port. It is suitable for occasions with fast lifting speed, dryness and small particles. The speed of the hopper is relatively high, generally 1-2 seconds per meter. To maintain this speed, the correct driving wheel must be selected. The speed and diameter are particularly important, and the choice of the discharge port cannot be ignored.

Advantages: Under the same hopper speed, the size of the driving wheel is small, the discharge position is high, the distance between each hopper is reduced, the height of the discharge pipe can be increased, and the height of the machine can be reduced.

Disadvantages: The hopper is relatively small, not suitable for all materials, and can only be used for powdery and granular materials with good fluidity.

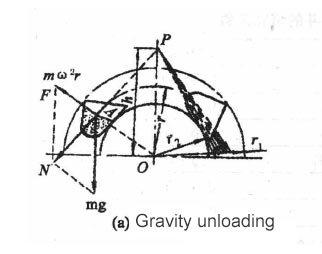

Under the action of gravity, the material falls along the back of the previous hopper. It is mostly used for materials with large volume and specific gravity. It needs to be equipped with a hopper with guide grooves. The running speed of the hopper is 0.4-0.8 seconds per meter.

Advantages: The loading performance of the hopper is good, and the size of the hopper has nothing to do with the limit distance. Therefore, while allowing a larger operating speed of the hopper, try to use a large-sized hopper.

Disadvantage: The position of throwing material is relatively low. To solve this shortcoming, it is necessary to increase the height of the head of the elevator. The material is thrown between the inner walls of the hopper at a running speed of 0.6-0.8 seconds per meter and chain traction.

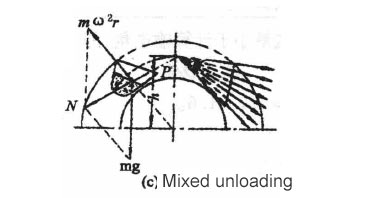

Centrifugal force + gravity, suitable for poor fluidity and wet materials. The hopper generally chooses a shallow hopper, and the distribution method is an interval layout to ensure the completion of unloading. This unloading method combines the advantages of centrifugal and gravity elevators, and is suitable for the transportation and lifting of most materials.

The above are the common unloading methods of bucket elevators. Bucket elevators are suitable for continuous vertical lifting of powdery, granular and fine materials, and can be widely used in various scales of feed mills, flour mills, rice mills, and oil mills. , starch factories, grain depots, port terminals and other occasions.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.