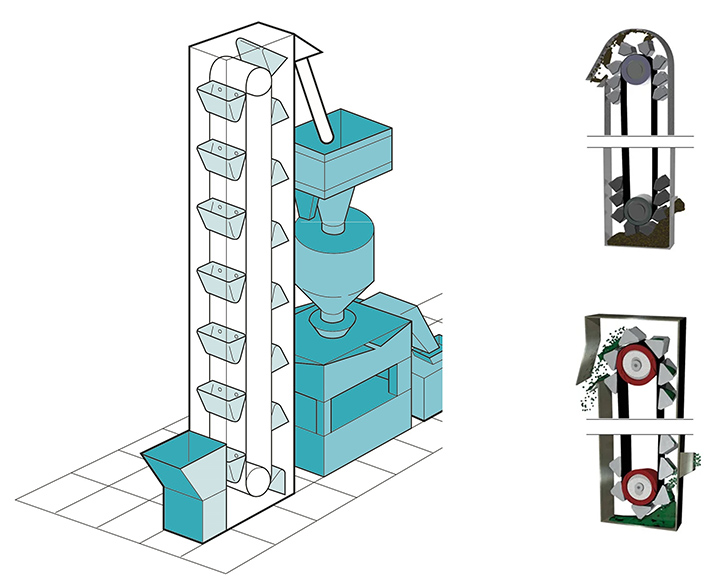

Used to lift and transport bulk materials (usually granular or powdered) vertically between different levels or heights

![]()

![]()

![]()

Price:$500.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Type: Belt/Chain

Material particle size: 25-70mm

Lifting capacity: 5.4-142 tons/hour

Lifting height: ≤40 meters

Lifting speed: 1.4-2 m/s

Material: carbon steel, stainless steel

Application: Continuous vertical lifting of powdery, granular and small materials. It can be widely used in feed mills, flour mills, rice mills and oil plants of various sizes.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

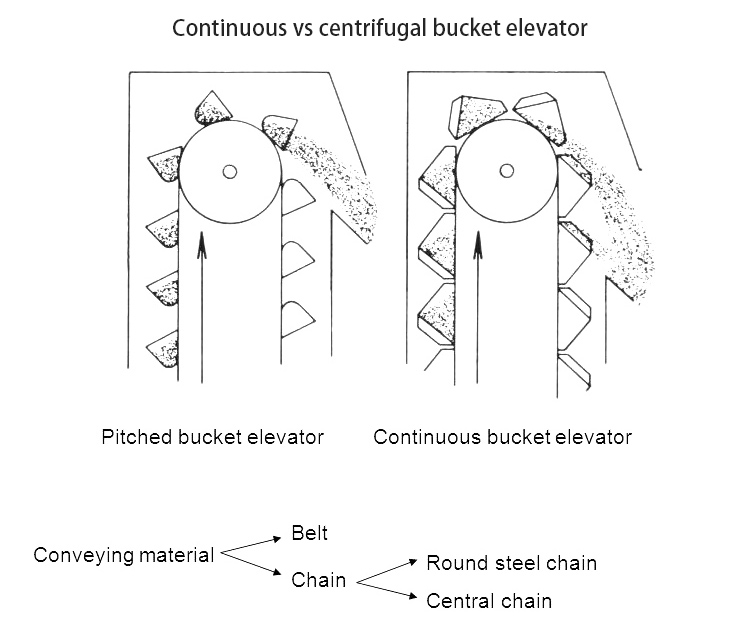

Continuous bucket elevator, also known as a continuous vertical conveyor, is a type of material handling equipment used to vertically transport bulk materials. Unlike centrifugal bucket elevators that operate intermittently, continuous bucket elevators provide a steady and uninterrupted flow of material.

Continuous bucket elevators are commonly used in industries such as agriculture, food processing, mining, chemical, and manufacturing, where a steady and controlled flow of materials is required. Their gentle handling, versatility, and customizable design make them suitable for a wide range of applications.

Here is a step-by-step explanation of how a continuous bucket elevator works:

Loading: The working process starts from the lower part of the elevator or the feeding port. The buckets are carried on a continuously looping belt or chain and move through the loading station or reclaim point. They take material from hoppers or feed conveyors as the buckets move along the bottom of the elevator.

Material Conveying: Once the material is loaded into the bucket, the bucket will continue to move along the endless belt or chain, carrying the material along with it. During the whole working process, the bucket always maintains a vertical position to ensure that the material is safely kept in the bucket.

Discharge: When the buckets reach the top of the elevator, they approach the discharge point. Depending on the design and configuration of the elevator, the bucket may tip or tilt to discharge. The bucket dumps the material into a chute, conveyor or processing equipment at the desired discharge location.

Continuous material flow

Provide stable and uninterrupted material flow. This continuous operation ensures consistent and efficient transfer of bulk materials, minimizing downtime and maximizing productivity.

Gentle handling

Used for gentle handling of materials, especially fragile or delicate materials. The bucket remains in an upright position throughout operation, preventing excessive shock or agitation that could cause material degradation or breakage.

Versatility

The continuous bucket elevator can handle a variety of materials, including grains, seeds, powders, granules, pellets, etc. They are suitable for use in various industries such as agriculture, food processing, mining, chemical and manufacturing, making them a versatile solution for different material handling needs.

Efficient Vertical Conveying

They can move material to considerable heights and distances, allowing seamless integration into handling systems or transfer of material between different levels of a facility.

Low maintenance cost

Compared with other types of elevators, the maintenance requirements of continuous bucket elevators are generally lower. Continuous gentle operation reduces wear and stress on equipment, reducing maintenance needs and extending equipment life.

Space saving

The continuous bucket elevator can be designed in a compact configuration, thus saving valuable floor space in the facility. They can be vertical or inclined and are suitable for installation in areas with limited available space.

| Comparative item | Continuous Bucket Elevator | Centrifugal Bucket Elevator |

| design | Has a continuous bucket ring connected to a belt or chain to create a continuous flow of material. The bucket remains in an upright position throughout operation, ensuring gentle material handling. | The buckets are mounted on a belt or chain at specific intervals. These buckets are designed to scoop up material at the bottom and discharge it at the top via centrifugal force. The bucket can be positioned at a more vertical angle than a continuous bucket elevator. |

| Features | Provides consistent and controlled material flow, making it suitable for handling fragile or delicate materials that require careful handling. | Provides a more aggressive material handling process for non-friable, free-flowing materials. |

| application | Used for handling materials that require gentle transport, such as grains, seeds, food and fragile materials in industries such as agriculture, food processing and pharmaceuticals. | Used for handling heavy, abrasive or non-friable materials such as coal, aggregates, sand, minerals and other industrial materials. |

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

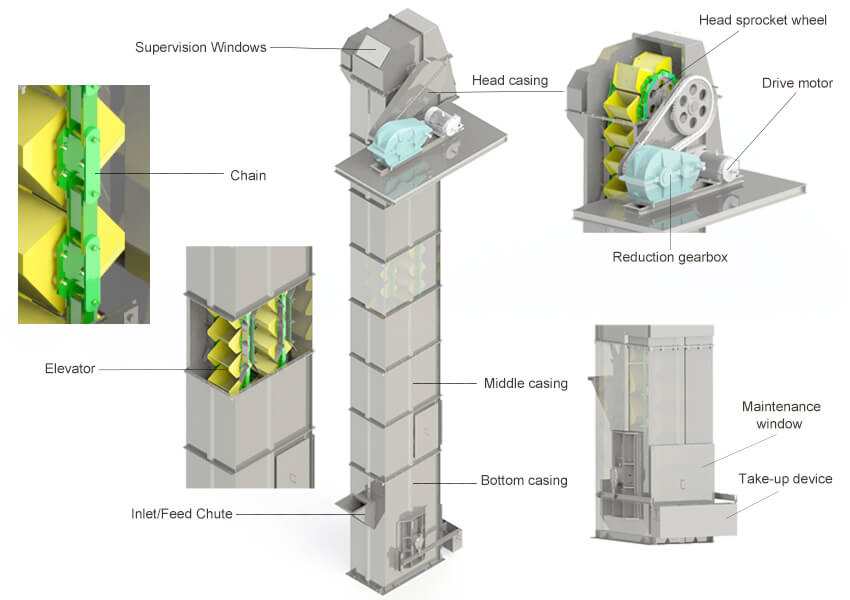

Head: The head is located on the top of the hoist and acts as the discharge point for the bucket. It contains head pulleys driven by a motor and provides the power to move the belt or chain. The head also includes a hood or cover to prevent spillage of material during operation.

Belt or Chain: A continuous endless belt or chain is the primary component that carries the bucket and facilitates material transport. The belt or chain is driven by the head pulley and guided by idlers or sprockets along the entire length of the elevator.

Buckets: Buckets are attached to a belt or chain at regular intervals, forming a continuous loop. They are designed to scoop up material at the point of loading and transport it along the path of the elevator. Buckets can be made of various materials such as plastic, metal or rubber, depending on the material being handled.

Enclosure: The continuous bucket elevator is enclosed within an enclosure, or enclosure, that provides structural support and contains the material being transported. Enclosures help prevent material spillage and provide a controlled environment for safe and efficient operation.

Drive system: The drive system consists of the motor, gearbox, and drive components that provide the power to move the belt or chain. The drive system is usually located at the head and is responsible for controlling the speed and direction of the elevator.

Continuous bucket elevators are ideal for a variety of applications where material integrity and gentle handling are crucial. Here are some of their key applications:

1.Friable materials: These are materials that crumble or break easily. The continuous discharge mechanism of these elevators avoids the high speeds and centrifugal force of centrifugal elevators, which can damage fragile materials. This makes them perfect for:

Food products like cereals, grains, and coffee beans

Pharmaceuticals and chemicals

Plastics and plastic pellets

2.Light and fluffy materials: Continuous bucket elevators can efficiently handle materials that tend to be airy or easily disturbed by high speeds. This includes:

Wood chips and sawdust

Powders like flour, powdered milk, and spices

3.Large capacity applications: While not quite as fast as centrifugal elevators, continuous bucket elevators can still achieve high capacities. They are a good choice for:

Grain storage facilities

Cement plants

Power plants (coal or biomass)

Abrasive materials: The continuous design can handle wear and tear from materials like sand, gravel, or clinker.

A fertilizer manufacturer introduced a continuous bucket elevator produced by Dahan to realize vertical transportation of fertilizer particles. The equipment improves production efficiency, reduces energy consumption and labor costs, and ensures product quality and production continuity. Customer feedback states that the reliability and efficiency of the continuous bucket elevator make the production process smoother, save costs for the company and improve competitiveness.

Xinxiang Dahan Continuous Bucket Elevator Manufacturer is a company specializing in the production of conveying equipment and has rich manufacturing experience and technical strength. The manufacturer is committed to developing and producing high-quality, high-efficiency continuous bucket elevators with a wide range of types to meet the different needs of customers. Dahan manufacturers focus on product quality and customer service, provide customized conveying solutions for various industries, and have won the trust and praise of customers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.