Uses chains and a series of buckets to transport bulk material vertically, scooping up material from a lower level and discharging it at a higher level.

![]()

![]()

Price:$550.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Chain Type: Round Link Chain

Delivery capacity: 5.4-365 cubic/hour

Lifting height: 40 meters

Equipment material: carbon steel, stainless steel

Material temperature: ≤250℃

Bucket capacity: 5.2~10L

Bucket speed: 1.25m/s

Motor power: 5.5~7.5KW

Application: It has a wide range of application precedents in the screening and classification of granular and powdery materials in chemical, food, metallurgy, mining, building materials, grain, abrasives, chemical fertilizers, and coal industries.

Applied materials: cement, raw meal, fly ash, flour, talcum powder, phosphate rock powder

Cain bucket elevator is a type of vertical conveyor that is used to move bulk materials vertically from one level to another. It is comprised of a series of buckets that are attached to a chain or belt that moves around a sprocket or pulley at the top and bottom of the elevator. The buckets are designed to scoop up the material at the lower level and then discharge it at the higher level.

Chain bucket elevators are commonly used in a range of industries for the vertical transportation of bulk materials such as grains, seeds, fertilizer, minerals, and other materials. They are typically designed to handle large volumes of material and can be customized for specific applications.

There are several types of chain bucket elevators, each with its own unique features and advantages. Some common types of chain bucket elevators include:

1. Centrifugal discharge elevators: These elevators are designed for high-speed operation and are commonly used in the grain handling industry. The buckets are spaced further apart than in other types of elevators, which allows for faster material discharge.

2. Continuous discharge elevators: These elevators are designed for slow and gentle handling of materials. The buckets are closely spaced together, which prevents material from spilling between the buckets during transport.

3. Positive discharge elevators: These elevators are designed to handle abrasive or sticky materials that can become lodged in the buckets. They feature a self-cleaning design that prevents material buildup and ensures smooth operation.

4. Super capacity elevators: These elevators are designed for handling large volumes of material and are typically used in the mining and chemical industries. They feature large buckets and heavy-duty construction to handle the weight and volume of the material.

5. Double-strand elevators: These elevators feature two chains or belts that work together to move the buckets. They are used for handling heavier loads and are commonly used in the cement and mining industries.

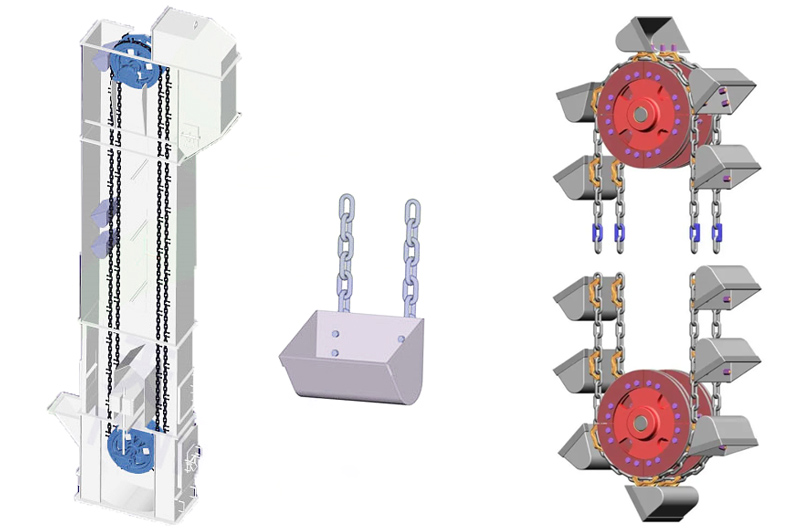

The operation of the chain bucket elevator can be divided into the following steps:

1. Material is fed into the bottom of the elevator and picked up by the bucket as it moves around the bottom sprocket or pulley.

2. The chain then moves the bucket up to the top sprocket or pulley where the material is discharged.

3. The hopper then returns to the bottom of the elevator, ready to shovel the next batch of material.

The speed of the chain or belt and the spacing between the hoppers can be adjusted to control the flow of material through the elevator. In addition, the discharge point of the elevator can be customized to meet the specific needs of different applications.

Efficient and reliable

It can process a large amount of materials at high speed, with minimal downtime or maintenance time, and the conveying capacity is more than 30% higher than that of ordinary models.

Versatility

Can be customized to meet the specific needs of different industries and applications, capable of handling a wide range of materials and operating conditions.

Operational security

Designed with safety features such as interlocks and sensors to prevent overloading or other potential hazards.

Low energy consumption

A relatively low energy input is required, making it a cost-effective option for vertical material handling.

Save space

The compact design and small footprint make it ideal for use in facilities with limited space.

Gentle handling

Can be designed to handle materials gently, reducing the risk of material being damaged or degraded during transport.

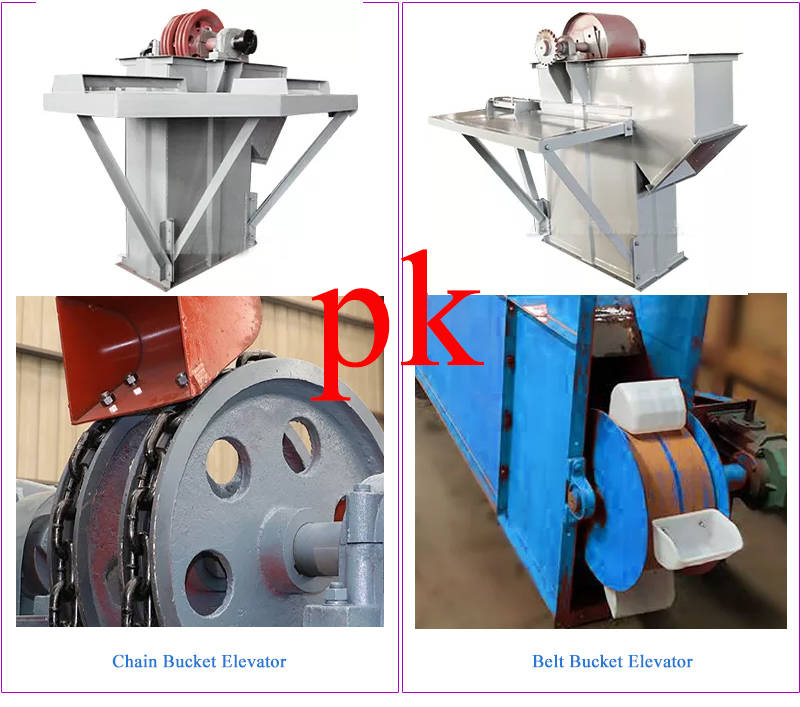

The main difference between a bucket elevator chain and belt lies in their design and application. Here are some key differences:

1. Design: A chain bucket elevator uses a chain to move the buckets while a belt bucket elevator uses a belt to move the buckets. The chain is made up of a series of links that interlock with each other, while a belt is a loop of material with a flexible design.

2. Strength: A chain is stronger and more durable than a belt, making it a better choice for heavy-duty applications or where the material being transported is particularly heavy or abrasive. A belt is generally less durable and is better suited for lighter-duty applications.

3. Speed: A chain bucket elevator can operate at higher speeds than a belt bucket elevator, making it a good choice for applications where high throughput is required. A belt bucket elevator is typically limited to lower speeds due to the design of the belt.

4. Maintenance: A chain bucket elevator requires more maintenance than a belt bucket elevator due to the need to lubricate the chain and replace worn links. A belt bucket elevator, on the other hand, requires less maintenance but may need to be replaced more frequently due to wear and tear.

5. Noise: A chain bucket elevator is generally noisier than a belt bucket elevator due to the clanking of the chain links as they move around the sprockets.

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

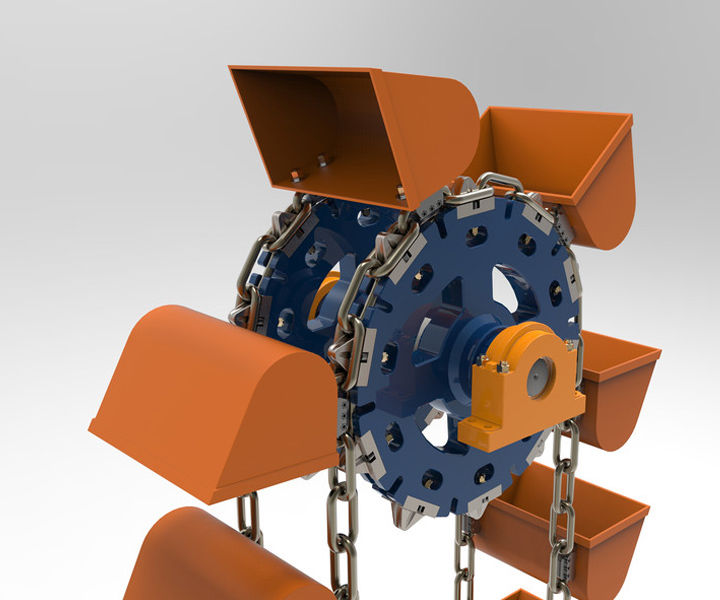

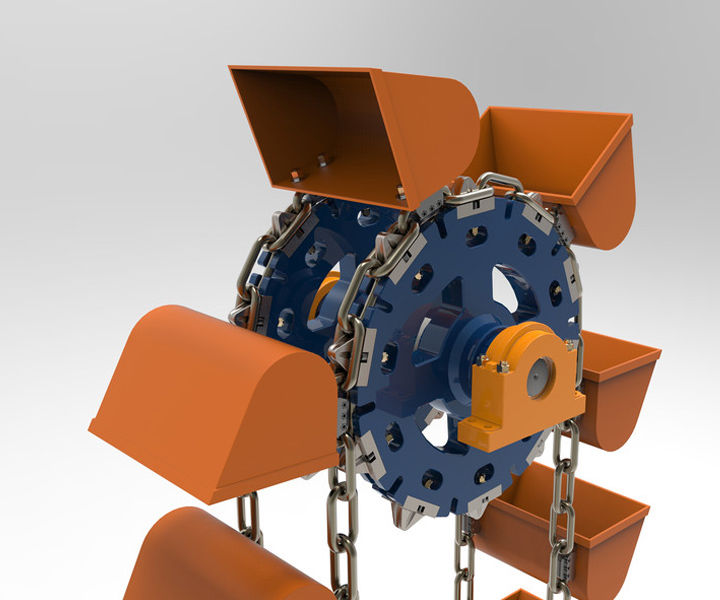

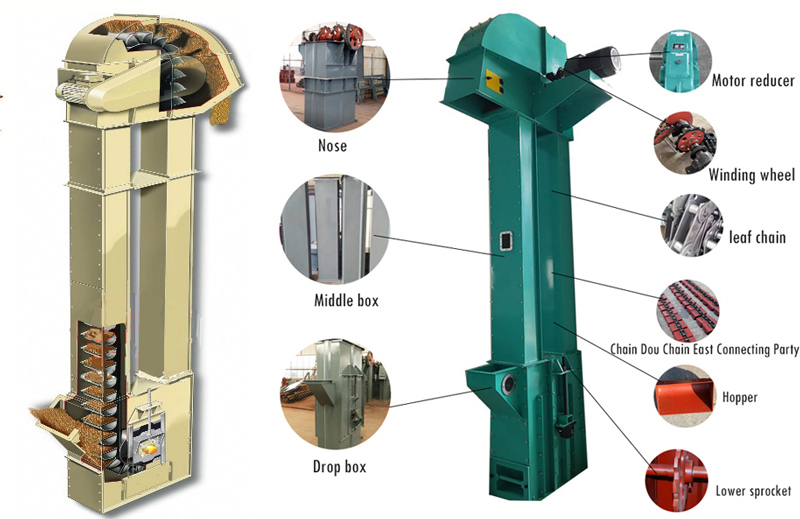

Chain bucket elevator consists of running parts, driving device, upper device, middle casing and lower device.

Running parts---consisting of hopper and special ring chain, the chain has high tensile strength and good wear resistance.

Driving device---using a variety of driving combinations to drive, (according to the actual needs of the user). The driving platform is equipped with a maintenance frame and a railing. The drive system is divided into two types: left and right.

The upper device---is installed with track (double-row chain), backstop, and the discharge port is equipped with an anti-return rubber plate.

Middle section---Part of the middle section is equipped with track (double chain) to prevent the chain from swinging during operation.

Lower device---installed with automatic tensioning device.

Ring chains are generally divided into TH160 bucket elevator chain (Φ14), TH250 bucket elevator chain (Φ18), TH315 bucket elevator chain (Φ20), TH400 bucket elevator chain (Φ20), TH500 bucket elevator Machine chains (Φ20) are the most commonly used in the market. After proper heat treatment, the round link chain has high tensile strength and wear resistance, and has a long service life.

Note: The dimensions in this table are for reference only. For details, please ask the technical department of our company for drawings. Among them, the key data C=axis center distance L=contour height H=lifting height

ZH type (medium-deep bucket) is generally used to transport wet, agglomerated, and difficult-to-throw materials, such as wet sand, molding sand, fertilizer, alkali powder, etc.

SH type (deep bucket) is generally used to convey dry, loose and easy-to-throw materials, such as cement, gravel, coal, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.