Wheat flour industrial grade single stage sieve is a device specially used to remove impurities from wheat flour. The sieving mesh range is usually 40-200 mesh (aperture 0.075-0.42mm), and it adopts the working principle of a single-layer rotary vibrating screen. In the production process of wheat flour, the vibrating motor drives the screen to move at high speed to accurately separate wheat flour of different particle sizes, and efficiently screen out bran, impurities or lumps, such as bran, stones, metal fragments, etc. These impurities will affect the quality and safety of wheat flour. The main function of the industrial-grade single-stage wheat flour sieve is to screen and remove impurities in wheat flour.

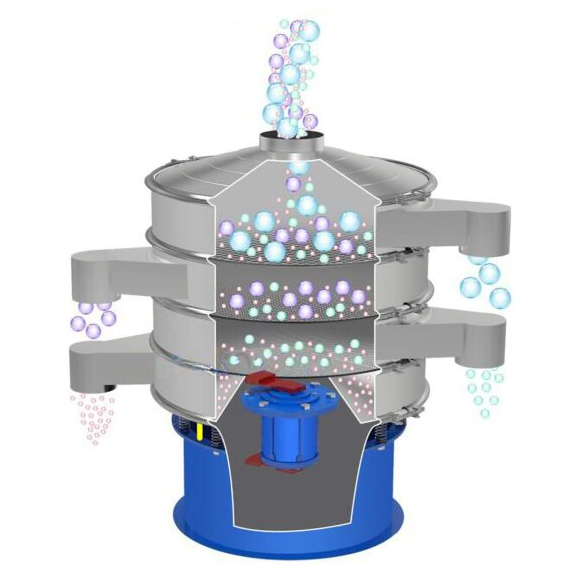

Wheat flour industrial grade single stage sifter usually consists of a single-layer screen and a vibrating motor. The wheat flour sample is placed on the sieve. When the equipment is started, the vibration motor will generate vibration force to sieve the wheat flour on the sieve. During the screening process, larger impurities and foreign matter are trapped by the screen, while the wheat flour passes through the screen aperture and is finally collected in the container below. In this way, the industrial-grade single-stage wheat flour sieve can effectively remove impurities in wheat flour and improve the purity and quality of wheat flour.

It can effectively remove the thread ends, drum skins, insect eggs, stones, metal impurities, etc. contained in the flour, effectively purify the flour, and improve the work efficiency of the food factory.

It is made of food-grade 304 stainless steel, which is not easy to rust and can avoid flour contamination. The sealing part is equipped with silicone material specially used in the food industry to meet the hygiene requirements of the food industry.

Improve the quality of baked products: When processing wheat flour, some contamination may occur, which is not conducive to the production of high-quality products. To make baked goods, an industrial-grade single-stage sieve for wheat flour must be used. The most important thing is that the flour should not contain unnecessary particles.

The compact design allows the sieve to be easily installed on any production line, and the fully sealed structure can avoid dust during the flour screening process.

Wheat flour industrial grade single stage sifter has many advantages. First of all, it can effectively remove impurities in wheat flour and improve production efficiency and product quality. Secondly, the equipment has a simple structure, is easy to operate and maintain, and is suitable for industrial production environments. In addition, it also has the characteristics of adjustable screening accuracy, and different screen apertures can be selected according to needs to meet the requirements of different particle size requirements for wheat flour impurity removal.

Wheat flour industrial grade single stage sifter is widely used in wheat flour production. First of all, it can be used for quality control of wheat flour, by screening and removing impurities to ensure that the purity and quality of wheat flour meet standards. Secondly, it can be used in the processing of wheat flour to prevent impurities from entering downstream equipment and protect the normal operation of the equipment. In addition, the wheat flour industrial grade single-stage sieve can also be used for the reprocessing of wheat flour to classify wheat flour of different particle sizes to meet the needs of different products.

Wheat flour industrial grade single stage sifter is a device used to remove impurities from wheat flour, using the working principle of a single-layer rotary vibrating screen. It can effectively remove impurities in wheat flour and improve the purity and quality of wheat flour. This equipment plays an important role in wheat flour production, ensuring product quality and safety, and meeting wheat flour processing with different particle size requirements.

vibro sifter

While removing impurities such as agglomerates and lint from the powder, it meets the primary requirements for food safety. At the same time, wheat flour is classified into different finenesses by increasing the number of screen layers.

Direct discharge sifter

It is mainly used to remove agglomerates, foreign matter and contaminants from wheat flour. Usually the impurity content is about 5%, so it is very suitable for screening wheat flour powder in large quantities.

Airflow screening machine

By utilizing the combined action of airflow and screens, impurities in wheat flour are separated and agglomerates in wheat flour can also be broken. The mesh size is 80-500 mesh, and the output is 5-10 times or higher than that of the vibrating screen.

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

The industrial-grade single-stage sieve for wheat flour, vibrating screen, shaking screen and other sieves produced and sold by Dahan Machinery are specially used for flour screening. They can screen to 500 mesh or 0.028mm. Impurities and coarse waste are automatically discharged and can work continuously.

Case 1: Flour processing plant

Wheat flour factories usually use multi-stage screening systems to achieve finer grading and higher output, remove impurities in wheat flour (such as insect eggs, black spot powder, lumps, etc.), and wheat flour industrial grade single stage sifteres may be used as a safety inspection link after initial cleaning.

Screening target: 10 tons per day

Screen mesh: 60 mesh, 80 mesh

Case 2: Premixed powder production line

Premixed powder production line is mainly used for raw grain cleaning, flour grading and bran separation. According to production needs and flour grades, the powder ratio is accurate, and different particle size grading and screening are required.

Screening target: 50 tons per day

Screen mesh: 80 mesh, used to remove fine lumps

Case 3: Export food powder packaging companies

Export food powder packaging companies may flexibly adjust the mesh according to market demand based on the product's requirements for fineness, and generally choose wheat flour industrial grade single stage sifteres with specific meshes.

Screening target: 60 tons per day

Screen mesh: 60-120 mesh or higher, to ensure uniform powder particles

The solution of wheat flour industrial grade single stage sifter is mainly used for grading and screening in flour processing to ensure uniform flour particle size to meet different product requirements. If you have more specific case requirements or other configuration requirements, please provide detailed information and I will provide you with a more suitable solution.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.