vibratory sifter

vibratory sifter circular vibratory sifter

circular vibratory sifter ultrasonic vibratory sifter

ultrasonic vibratory sifter mobile vibratory sifter

mobile vibratory sifter vibratory sifter screen separator

vibratory sifter screen separator

Sieving, peeling, sieving and separation of dry bulk solids and solid-liquid separation

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Function: Screening\separation\sorting\sieving\Grading

Diameter: 400mm-2000mm Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Layer(s): 1-5 Layers

Voltage: 220v/380v/customized

Material: Carbon Steel/Stainless Steel 304/316L

Application: Processes for sieving, sieving, classification for solid-liquid separation, separation of desired and undesired elements from a combination of solids to solids (where two solids often have different properties) and solids to liquid materials

Commitment:

Vibratory sifter is a kind of sieving or separation of materials by vibration, so that the products smaller than the screen size can pass through the screen smoothly, and the larger particles are left on the screen surface and discharged from the corresponding outlet to remove the raw materials. of oversized contaminants and agglomerates, ideal for screening incoming ingredients and final inspection of finished products, and grading to particle size requirements.

You can install 1 to 4 separation stages per vibratory sifter, resulting in 2 to 5 product fractions. A wide range of models (from Ø 400 to Ø 2000 mm) can meet any type of requirement. Moving wheels, sight holes, valves, magnets, frequency converters, labeling services and OEM orders are available upon user request.

Impurity Removal: Used to remove broken or undersized products such as lumps and other contaminants for final quality checks.

Particle Size Classification: Precisely separate particles of different sizes from the product, so that the final material is classified into different sizes. This is usually achieved by passing the product through a grid of up to 5 different aperture sizes.

Solid-liquid Separation: It can quickly remove insoluble solid substances in various slurries, and can contact slag discharge. Most are single-layered, but multiple layers can also be used.

Batch Screening: Improves product quality and safety by breaking down lumps and filtering out oversized particles, contaminants and debris for smaller processes, batches or short production runs.

Vibratory sifter has diameters of 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, and can also be customized for you. It allows throughputs from 100 to 3300 kg/h, depending on the product, mesh size and feed flow of the machine. It is suitable for sieving from 36 microns to 25 mm.

1.Standard type vibratory sifter: A commonly used type, widely used, suitable for screening and filtering powdery, liquid, granular and other materials, equipped with one or two vibrating motors, and the eccentric blocks at the upper and lower ends of the motion generating part make the machine vibrate around the center of gravity. These devices are mainly used for single-pass small batch operations: 100kg to 3300kg at a time.

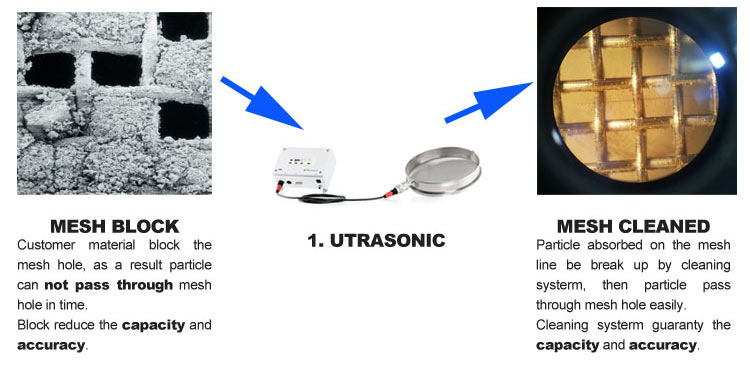

2.Ultrasonic vibratory sifter On the basis of the rotary vibrating screen, an ultrasonic screening system is added, which is suitable for the screening of fine powders within 80-600 mesh, solves the problem of blocking the screen, and the output can be increased by 0.5-10 times.

3.Gyratory vibratory sifter: Produces a horizontal rotary sieving action ideal for peeling, grading or fines removal from dry free-flowing powders. This screening motion retains material longer, has a slower and gentler screening action, and minimizes vertical agitation. These properties allow the finer material to stay in contact with the screen for longer, giving the material the greatest chance of passage without the help of an external force, resulting in a more accurate separation.

Feed the material to be separated through the feed port (feed port at the top of the circular vibrating screen), make sure the cover plate, screen structure and base are fastened with snap rings, due to the unbalanced weight assembly, the vibration motor will be energized, causing vibration Movement, the screen will start to vibrate, then, the material fed into the hopper will pass through the sieve according to the particle size, the material larger than the mesh size stays on the screen surface and is discharged from the coarse material outlet, and the material smaller than the mesh size falls into the The lower layer, according to the design of the vibrating screen, you can configure 1-5 layers of screens to achieve particle size classification.

Dust cover: It confines the material and keeps the machine and surroundings free from dust.

Vibration motor: Adopt YZUL vertical vibration motor, power 0.18KW-4.0KW, it is this motor that causes horizontal, inclined, vertical three-dimensional movement, this movement will increase the speed of materials passing through the circular vibrating screen, in order to achieve this, The device is equipped with an unbalanced weight assembly.

Screen frame: The thickness of the material is 2.0mm~3.0mm, generally made of stainless steel, and carbon steel can also be selected, which limits the product to be processed to the required size and fineness.

Brace ring: it is used to connect the bottom cone and the screen frame, the upper and lower screen frames, and also to prevent material leakage.

Screen: maintain tension to make it easier for the material to move in the direction of vibration, commonly used 304 stainless steel braided mesh.

Perforated plate: carrying the screen and prolonging the service life of the screen.

Cleaning device: remove blockages in the screen holes and increase production. It is made of silica gel and rubber bouncing balls. Ultrasonic cleaning device (635 mesh) can also be selected.

Improve product quality

Powders, agglomerates in granules, impurities and over-contamination can be easily removed, making them ideal for screening incoming ingredients and final production inspections of finished products.

Sieve in fine mesh

Capable of sieving up to 500# and delivering the desired output to provide accurate particle size without clogging.

High throughput

Heavy-duty motion generators generate higher vibrations, resulting in 3x higher throughput through precise screening, allowing production volumes from 100 to 3300kg/h per hour.

5 levels of gradation

The Vibratory sifter provides up to 5 levels of classification in one operation for precise particle size distribution.

Reduce cleaning downtime

The unit can be easily disassembled without tools and all contact parts are fully washable.

Safeguard operator health and safety

The seal is designed to stop any dust particles from leaking out of the sieve, protecting it from harmful dust.

Vibratory sifter for metal powder

ibratory sifter with ton bag automatic unpacking silo

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Vibratory sifter can be used at the same time for 1-5 layers according to the different needs of customers, ranging from screen diameter 400-2000mm, 1-5 layers, 304 stainless steel and carbon steel materials, etc. Various models are complete, and can also be customized according to customer needs.

In addition to the standard vibratory sifter, individual designs can also be adopted according to the screening products and the on-site needs of the production line:

1. Gate type: The gate design can control the residence and screening time of materials on the screen, ensure the processing accuracy of difficult-to-screen materials (viscous and fine materials), and increase the processing capacity.

2. Edged type: The feeding port is designed to be heightened and protected. The edged design can increase the feeding amount, prevent the material from splashing, and observe the condition of the screen.

3. Anti-corrosion type: The part in contact with the material is made of polypropylene (PP plastic), which is a screening solution for corrosive materials such as carbon steel and stainless steel.

4. Explosion-proof type: The motor adopts special design, and the whole machine has better sealing performance, which is suitable for the screening requirements of special industries (powder, materials prone to static electricity, etc.).

5. High-frequency type: use high-frequency vibration motor (3000RPM) as the excitation source, good at filtering materials such as ceramic glaze.

6. With hopper: The material can be filled up in the silo at one time, and the flow rate of the material entering the vibratory sifter can be controlled by adjusting the butterfly valve on the silo for screening.

Ultrasonic deblinding system

It enables sieving on finer meshes (down to 20 microns) without any blocking or blinding of the aperture. It also increases throughput and reduces cleaning times.

Screen deck lifting system

Multiple screen plates can be lifted to a height quickly and safely for comfortable access to the screen that needs to be checked or replaced.

As a professional screening solution provider, we can provide customers with high-quality screening equipment and provide detailed technical support. According to the specific requirements of customers, the overall design and construction plan are tailor-made. Through the optimized combination of various types of equipment, different process requirements can be met.

| Image | Material | Proportion | Mesh | Model | Method | Processing Capacity(Kg/h) |

|

Wheat Starch | 1 | 250 mesh | DH-1200-1S | Wet | 3200 |

|

Flour | 0.6 | 24 mesh | DH-1000-1S | Dry | 1500 |

|

Medicine Powder | 0.8 | 80 mesh | DH-800-1S | Dry | 550 |

|

Soy Sauce | 1 | 100 mesh | DH-1200-1S | Wet | 6500 |

|

Salt | 1.2 | 30/80 mesh | DH-1500-1S | Dry | 5000 |

|

PVC Resin | 1 | 0㎜/5㎜ | DH-1200-2S | Dry | 3000 |

|

Graphite | 1.2 | 16/40/80 mesh | DH-1000-3S | Dry | 1400 |

|

Aluminum Powder | 0.9/1.2 | 80/120 mesh | DH-800-2S | Dry | 350 |

|

Emery | 4 | 60 mesh | DH-1000-1S | Dry | 300 |

|

Spray Soil Particles | 2 | 10 mesh | DH-1000-1S | Dry | 18000 |

|

Mud | 1.1 | 250 mesh | DH-1000-1S | Wet | 3200 |

Since its establishment 12 years ago, Dahan Machinery has a factory area of 10,000 square meters, providing screening solutions for food, medicine, chemical industry, metallurgy, building materials and other industries. Cooperative customers include Coca-Cola Company, Sundaban Industrial Complex Co., Ltd., etc. The company has ISO quality system certification and EU CE certification, and the product quality is guaranteed.

Quality: 30-day refund for quality problems, 180-day replacement for quality problems, 1-year warranty, and lifetime maintenance.

Service: 30 minutes to respond to demand, we can design suitable screening and filtration solutions for you according to your needs.

Delivery: Regular models will be delivered within 24 hours, and customized models will be delivered within 7 days, which reduces the delivery cycle and saves user costs.

Q: What are the sizes of vibratory sifter?

A: We are available in 16", 24", 31", 39" 16", 59", 70" and 79" sizes.

Q: What is sifting in pharmaceutical industry?

A: Vibratory sifter is an essential part of every pharmaceutical production process, eliminating excess contamination to ensure the quality of ingredients and finished products during production and before use or packaging.

Q: How many types of sifters are there?

A: Today the market has three popular sifter classification types:

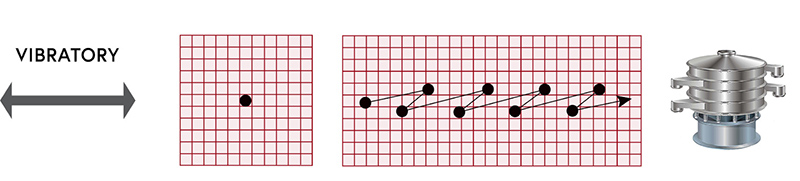

1. Vibratory – This type of machine uses a circular or linear motion with a vertical component.

2. Centrifugal - Force and rotary motion

3. Gyratory - uses a circular horizontal motion

Q: What is process of Sifter?

A: The material is sifted during rotation. The product particles that are small enough pass through the screen, while contaminants and larger particles are discharged through a special outlet.

Q: How about the packing of machine, can I use my own logo on packages?

A: A:Normally packed in fumigation-free plywood case. We can mark your own logo on the packages. And also can be neutral packing for your convenience.

Q: What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.