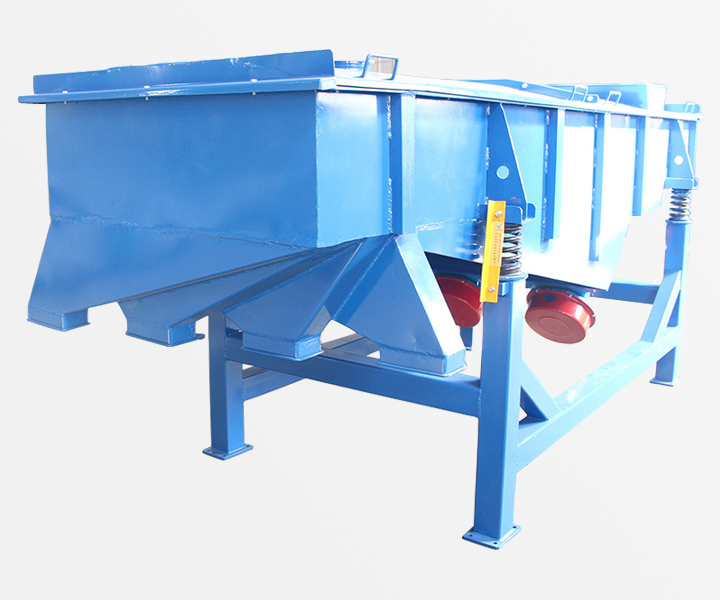

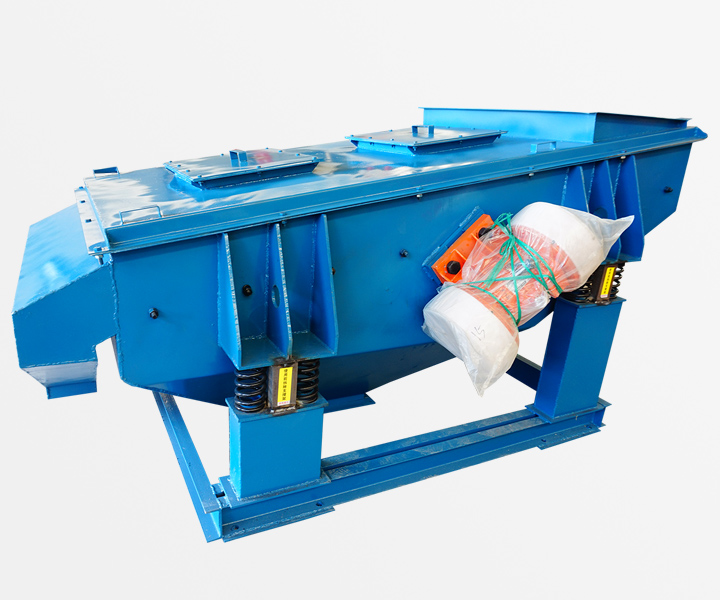

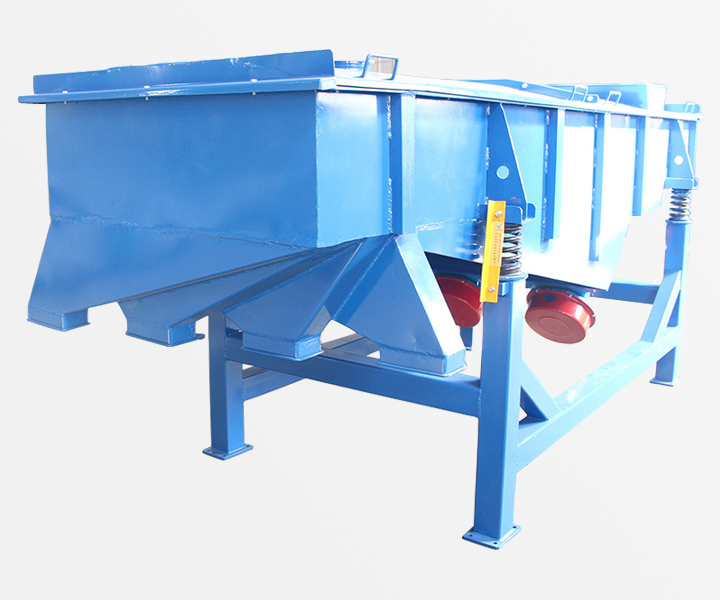

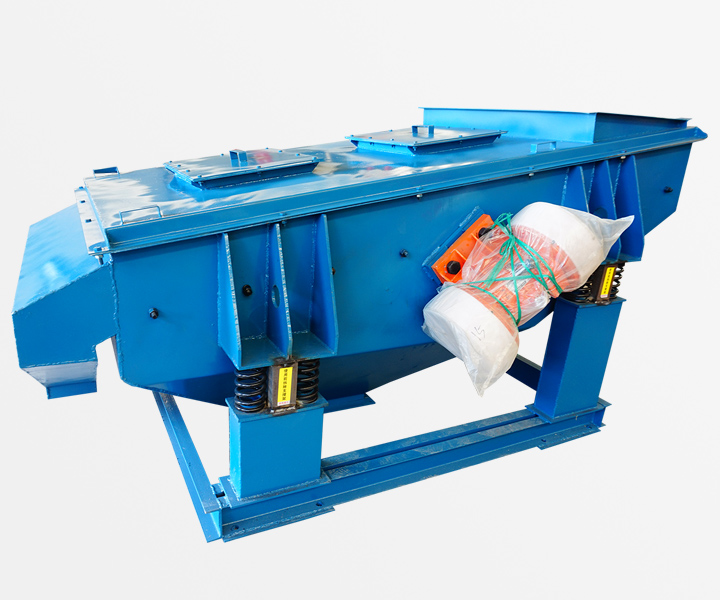

Rectangular vibrating screen

Rectangular vibrating screen Rectangular Vibrating Screen

Rectangular Vibrating Screen Linear Vibrating Screen

Linear Vibrating Screen Vibratory Classifying Screens

Vibratory Classifying Screens Heavy-duty vibrating equipment

Heavy-duty vibrating equipment

Used to screen out impurities in various materials and separate large and small particles

![]()

![]()

![]()

Price:$800.00-$8,000.00 /Set

Consult now and enjoy a 10% discount

Mesh number: 400 mesh

Feeding particle size: 0.074-10mm

Capacity: 0.12-20 tons/hour

Motor Power: 2*(0.4-3.7)kw

Application: Screening of powder, granular, block or liquid materials in mining, coal, smelting, building materials, refractory materials, light industry, chemical industry, medicine, food and other industries

Commitment:

Vibrating equipment is to separate materials according to basic particle size, sort by shape, sort by particle size, exclude foreign matter, prepare material for later processing, etc. Each sieve is designed to maximize the amount of particles that should pass through the sieve plate actually The probability that it does pass through the sieve, thereby providing the highest possible particle size separation.

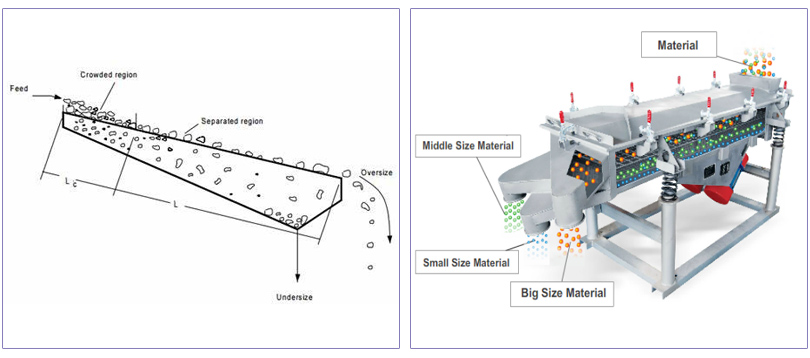

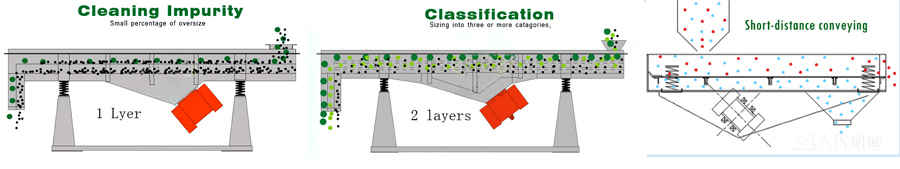

Product classification: Due to the vibration of the screen box, the material layer on the screen is loosened, thereby removing the gaps existing in the large particles and further expanding, and the small particles take the opportunity to pass through the gap and transfer to the lower layer, because the gap between the small particles is very small, and the large particles Can not pass, so the originally disordered particle separation, that is, according to particle size classification, Vibrating equipment can achieve 2-7 different grades in one operation.

Removal of impurities: Protect the quality of powder or granular products by removing excessive contaminants by taking advantage of the shape, specific gravity, or particle size of the material.

Short-distance conveying: The vibration of the vibrating motor is used to make a parabolic forward motion on the screen, resulting in the transfer of the position of the material, so as to realize the short-distance conveying of the product.

Here are some common types of vibrating equipment used in various industries:

The raw materials are screened according to different particle sizes through the vibrating screen to achieve the classification of coarse and fine particles.

Application: Mining, building materials, chemicals, food processing, pharmaceuticals, cosmetics, metal processing, environmental protection, agriculture, papermaking and other industries, used for screening, grading and processing of raw materials

Transfers materials from one location to another through vibration, and can be used to evenly feed materials to downstream equipment.

Application: Used for powdered, granular, small block materials in mining, building materials, metallurgy, chemical industry, food processing, pharmaceuticals, agriculture and other fields.

Used to evenly and continuously feed materials to downstream equipment such as crushers, mills, etc., and can accurately control the flow of materials.

Application: Used for feeding materials such as ore, coal, sand and gravel, concrete, chemical raw materials, etc.

Vibrating equipment uses the vibration motor as the vibration source and is driven by double vibration motors. When the two vibration motors are rotated synchronously and in reverse, the exciting force generated by the eccentric block of the vibration motor cancels each other in the direction parallel to the axis of the vibration motor. The direction perpendicular to the axis of the vibration motor overlaps as a resultant force, so its running trajectory is a straight line, and the two motor shafts have an inclination angle relative to the screen surface. Under the combined force of the excitation force and the self-gravity of the material, the material is thrown and jumped on the screen surface It moves forward in a straight line, sieves various specifications of the above and below the sieve through the different levels of the screen, and then discharges it from different discharge ports into the silo or the material barrel.

1.High throughput

The width of the screen surface is from 500mm to 1500mm, and the length of the screen surface is from 2000mm to 4000mm, Due to its larger screening area, it gives high efficiency of the material while sieving. The production capacity can reach 20 tons per hour.

2.Double motor

Equipped with dual motors, mounted perpendicular to each other for proper vibration flow. The arrangement of the double motors makes the screen frame move and vibrate in a straight line perpendicular to the motor, so that the super large particles have a good forward effect.

3.Multilayer separation

Vibrating equipment can provide up to 5 stages of classification in a single operation for precise particle size distribution

4.Adjustable

Equipped with an adjustable vibration motor to help achieve different speeds and vibration levels depending on the settings.

Sieving wheat bran

Grading of stones

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Vibrating equipment can be used to screen, classify, deblock, dewater any bulk solids or slurries and was invented to handle high feed flow rates where the application requires screening in large volumes. It provides maximum throughput with precise grading. Commonly used in: ferrosilicon, sand, pepper granules, wheat peel, pumpkin seeds, silicon powder, sugar, traditional Chinese medicine, betel nut, silicon carbide powder, stone, activated carbon granules, soil, gravel, millet, ore pulp, shells, cooked sesame, mechanism Sand, chrysanthemum, quartz sand, construction waste, coke powder, plastic particles, river sand and other materials.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.