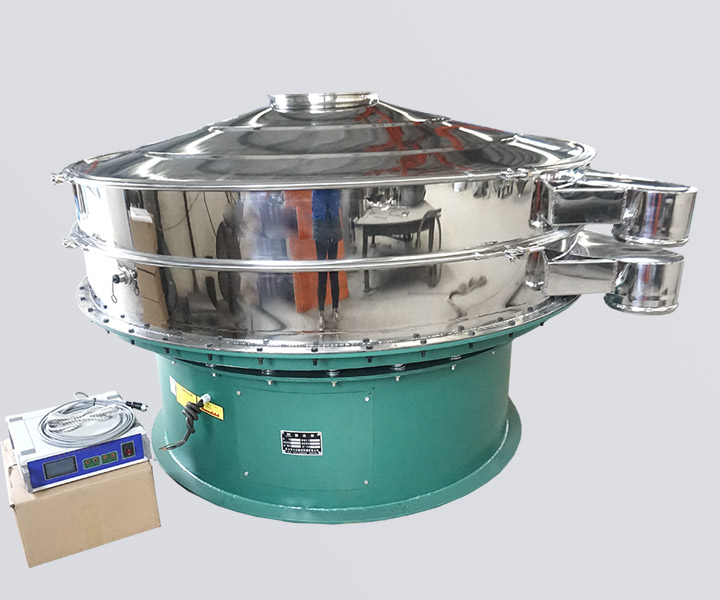

Used to remove foreign contaminants and exfoliate oversized particles and agglomerates, graded according to particle size requirements

![]()

![]()

Price:$800.00-$4,900.00/Set

Consult now and enjoy a 10% discount

Diameter: 400-2000mm

Mesh Size: 0-500

Capacity: 100-5000kg/h

Layers: 1-5 layers

Material: carbon steel/stainless steel/plastic

Applications: Designed to ensure your final product meets required specifications and is suitable for use in all industries including food, pharmaceutical, additive manufacturing, chemicals, coatings, ceramics, metal powders, water treatment, recycling, and more.

Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Industrial sifter is used for accurate batch grading or safe screening of powders and liquids, it removes oversized contaminants from your powders and liquids, it can also accurately separate your powders and granules It can be divided into different sizes, And can grade up to 6 levels of material in one operation. Widely used in food and beverage, medicine, powder coating, metal powder, chemical industry, agriculture, plastics and other industries.

Available in a variety of sizes and options (from 15" (400mm) to 78" (2000mm)), the Industrial sifter can be customized to your exact specifications, sieving up to 500 mesh, providing accurate particle size, and professionally installed The latest screen cleaning system can easily solve the problem of screen blockage.

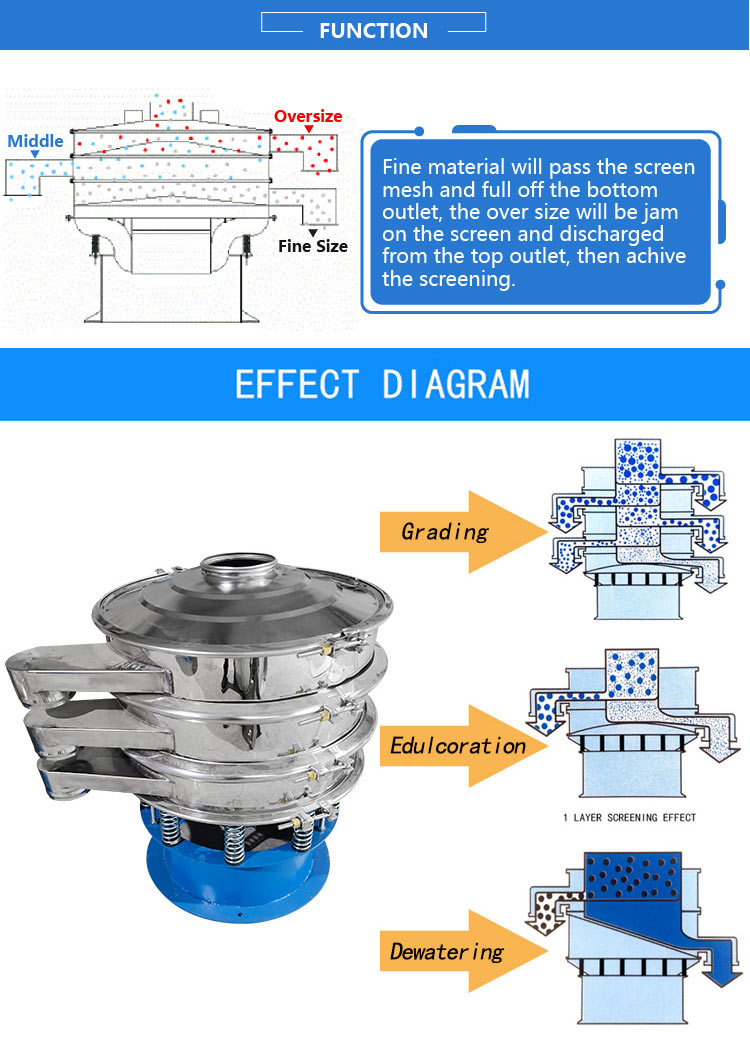

Screening Impurities: Used to remove broken or undersized products such as lumps and other contaminants for final quality checks.

Particle Size Classification: Similar to inspection sieves, but provides more precise separation of sieved products. The purpose of industrial grading sieves is to accurately separate particles of different sizes from the product, so that the final material is classified into different sizes. This is usually achieved by passing the product through up to 5 screens of different apertures.

Solid-liquid separation: It can quickly remove insoluble solid substances in various slurries, and can continuously discharge slag. Most are single-layered, but multiple layers can also be used.

Batch Screening: Improve product quality and safety by breaking down clumps and filtering out oversized particles, contaminants and debris for smaller processes, batches or small batches.

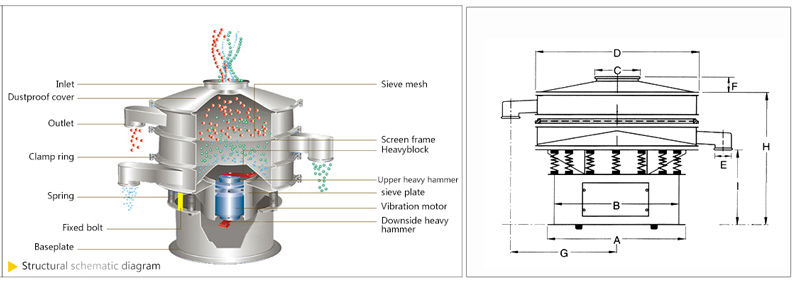

Vibratory sifter

For continuous separation of dry bulk materials and removal of foreign contaminants and agglomerates, multi-layer classification by particle size.

Screen size: 2-500 meshM

Capacity: 100-3300kg/h

Ultrasonic Vibrating Screen

Using the ultrasonic system to vibrate the screen mesh, prevent blinding and clogging of the mesh, and increase the capacity by 1-10 times.

Screen size: 2-625 mesh

Capacity: 100-5000kg/h

High Frequency Vibrating Screen

The high-frequency version is dedicated to screening glazes and other viscous fluids such as ceramics (slurries, glazes), paints, coatings, etc.

Mesh size: 0.01-5mm

Capacity: 200-1200 Liter/hour

Tumbler Screen

Especially suitable for high feed and multi-layer separation of fine, fragile and light products that are difficult to screen.

Screen size: 2-500 mesh

Capacity: 6-60t/h

Direct Discharge Sifter

Remove lumps, foreign bodies and contaminants to ensure the safety, hygiene and quality of the final product.

Mesh size: 5-100 mesh

Capacity: 0.1t/h-10t/h

450 Filter Sieve

It can quickly remove insoluble solid substances in various slurries, and can continuously discharge slag

Mesh size: 2-400 mesh

Capacity: 400-1200

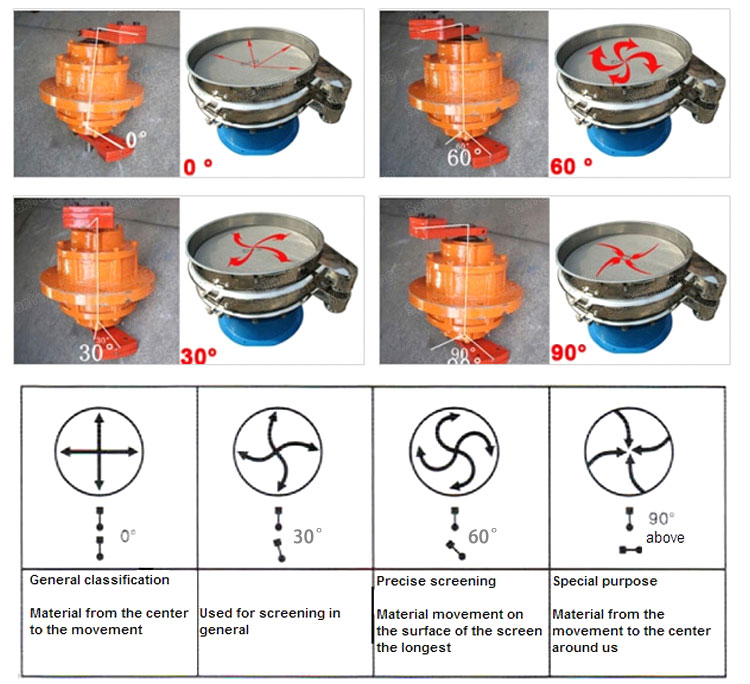

Industrial sifter screens products by using customized layered sieves and 3D motion. The screened products enter the equipment through the feed port, and pass through 1-5 layers of screens with different meshes to complete the screening and classification. Make the products smaller than the size of the screen smoothly pass through the screen and fall to the lower layer, while the larger particles stay on the screen and are discharged from the corresponding outlet.

Improve product quality

It can be used for safe screening to remove foreign matter, separation process of solids in liquid, separation of different particle sizes in the same product, etc.

Fine mesh sieve

Screening up to 500 mesh, providing accurate particle size, and installing a professional screen cleaning system to easily solve the problem of screen blockage.

6-stage separation

Product can be graded into 6 or fewer differently sized fractions to achieve uniform particle size distribution.

Can be produced continuously

The impurities and coarse materials after screening are automatically processed, saving labor, and after screening, it can automatically enter the next round of screening work, continuous operation.

Easy to clean

Quick and easy removal without tools, manual quick release clamps allow for quick screen changes and easy cleaning.

Easy to arrange

The compact all-in-one screening machine is easy to operate, has a small footprint and can be used in different locations in your plant.

| Model | DH-600 | DH-800 | DH-1000 | DH-1200 | DH-1500 | DH-1800 | DH-2000 |

| Diameter (mm) |

Φ600 | Φ800 | Φ1000 | Φ1200 | Φ1500 | Φ1800 | Φ2000 |

| Screen area (m) |

0.24 | 0.45 | 0.67 | 1 | 1.6 | 2.43 | 3.01 |

| Mesh specification (mesh) |

2-500 | ||||||

| Feed particle size (mm) |

<Φ10 | <Φ15 | <Φ20 | <Φ30 | <Φ10 | <Φ15 | <Φ20 |

| Vibration times (rpm) |

1500 | ||||||

| Effective screen surface diameter (mm) |

Φ560 | Φ760 | Φ930 | Φ1130 | Φ1430 | Φ1760 | Φ1960 |

| Layers | 1-5 | ||||||

| Power (Kw) |

0.25 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 |

| Capacity (kg/h) |

100 | 200 | 500 | 800 | 1200 | 1800 | 2000 |

Industrial sifter can be customized according to the application industry, such as the height of the sieve machine, the length of the discharge port, the addition of dust removal ports, the addition of iron removers, the size of the feed port, air-tight screening, and other special use environments and specific use conditions. Here are a few common customization types:

Edged type: The heightened protection design is carried out for the material inlet. The edged design can increase the amount of feed, prevent material splashing, and observe the condition of the screen.

Gate type: Through the gate design, the residence and screening time of materials on the screen can be controlled to ensure the processing accuracy of difficult-to-screen materials (viscous and fine materials) and increase the processing capacity.

Anti-corrosion type: The part in contact with the material is made of polypropylene (PP plastic), and it has a solution for screening corrosive materials such as carbon steel and stainless steel.

Explosion-proof type: The motor adopts a special design, and the whole machine has better sealing performance, which is suitable for the screening requirements of special industries (powder, materials prone to static electricity, etc.).

Airtight type: install gas protection device, inert gas can avoid the deterioration of screening products in contact with air, carbon dioxide, etc., suitable for 3D printing materials, silicon carbide, alloy powder, metal powder, etc.

Iron removal type: Add a strong magnetic rod to reduce or remove the iron element in the screening material. The amount of iron-containing material in the screening material can be increased in different quantities, and the strength of the strong magnetic rod is different. Specifically, the strong magnetic bar box can be installed at the material inlet or the material outlet according to the usage.

| Screening products | Proportion | Mesh size | Capacty ((kg/hr t/hr)) |

Model |

| wheat starch | 1 | 250 mesh | 3200 t | DH-1200-1S |

| flour | 0.6 | 24 mesh | 1500㎏ | DH-1000-1S |

| soy sauce | 1 | 100 mesh | 6500 t | DH-1200-1S |

| salt | 1.2 | 30/80 mesh | 5000㎏ | DH-1500-1S |

| corn starch | 0.6 | 40 mesh | 1600㎏ | DH-1000-1S |

| pharmaceutical powder | 0.8 | 80 mesh | 550㎏ | DH-800-1S |

| PVC resin | 1 | 10㎜/5㎜ | 3000㎏ | DH-1200-2S |

| polyethylene powder | 0.45 | 48/100 mesh | 100㎏ | DH-800-2S |

| graphte | 1.2 | 16/40/80 mesh | 1400㎏ | DH-1000-3S |

| lead powder | 11.34 | 10/80 mesh | 1000㎏ | DH-1000-2S |

| emery | 4 | 60 mesh | 300㎏ | DH-1000-1S |

| Kaolin | 0.4 | 100 mesh | 200㎏ | DH-1000-1S |

| mud | 1.1 | 250 mesh | 3200㎏ | DH-1000-1S |

How Industrial Sifter Helped Different Industries:

Industrial Sieve for Glass

Different glass powder particle sizes, different lengths of glass fibers, and different sizes of glass beads have different uses. This requires screening equipment to classify different glass raw materials according to different uses, thereby improving the performance of glass products.

Circular Vibrating Sieve for Spices

Removal of impurities and sorting of different particle size groups of broken bulk materials with different particle sizes for packaging.

Filter Sieve For Soy Milk Filter

Mainly used in families and small hand workshops, by using a soy milk filter vibrating screen to separate soy milk and soy dregs to improve the taste of soy milk.

1、Our factory

2、Product display

3、Customers visit and test the machine

4、Qualification honor

Address:China,Yanjin county forest park gate to the west 1000 meters north road.