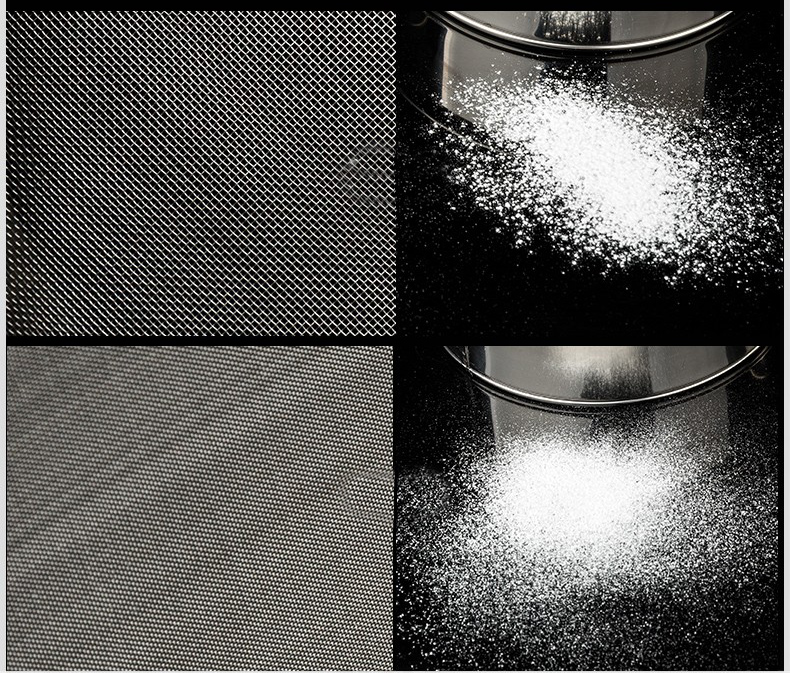

The ultrasonic vibrating sieve screening system is a simple, practical and reliable screening system. It is the most effective solution to the current mesh blockage. It is a major technological breakthrough in the domestic screening industry. For screening problems such as agglomeration, high static electricity, high fineness, high density and light specific gravity, for fine powder, ultrasonic vibrating sieve can be used for screening.

Ultrasonic vibrating sieve converts 220V, 50Hz or 110V, 60Hz electrical energy into 18KHz high-frequency electrical energy, inputting the ultrasonic transducer to turn it into 18KHz mechanical vibration, which greatly improves the various effects of the vibrating screen, so as to achieve high-efficiency screening and the purpose of clearing the net. The vibration frequency of the general vibrating screen is 1460 times per second, while the ultrasonic vibrating sieve is 36,000 times per second, which truly realizes the combination of sound wave and vibration frequency double vibration. sieve stands out from ordinary light-duty screening equipment and has become a high-efficiency screening equipment favored by ultra-fine segment customers. Improve the leveling and sliding effect of low-density powder in gravity sedimentation (light contact between the powder and the mesh port), improve the retention or wedging of high-density metal in the mesh port, and improve the adhesion effect of electrostatic powder, thereby improving Screening efficiency and screening quality. Expressed by the screening pass rate, in general, the pass rate can be increased by 50%-400% compared with no ultrasonic vibrating screen, the screening accuracy can be increased by 1-100%, and the output can be increased by 1-8 times.

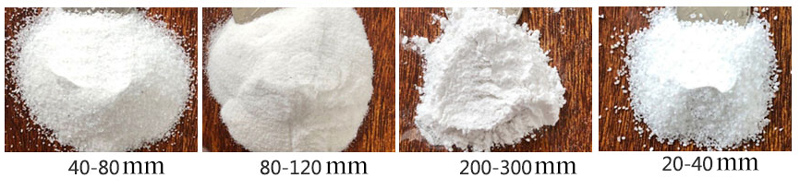

ultrasonic vibrating sieve has been successfully applied to the screening and classification of 400 mesh, 500 mesh and 600 mesh ultrafine materials, such as: silicon carbide, alloy powder, molybdenum powder, stainless steel powder, tungsten powder, nickel powder, cobalt powder, powder coating, quartz Powder, fluorite powder, bumethidone powder, malt powder, ribavirin, coffee powder, electromagnetic powder, negative electrode material, laser powder, electromagnetic powder, magnesium oxide, lithium battery positive electrode material, negative electrode material, carbon powder, powder coating, spore powder Sifting and so on.

The above is the application of ultrasonic vibrating sieve in fine powder. If you have related needs, you can contact Dahan Machinery.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.