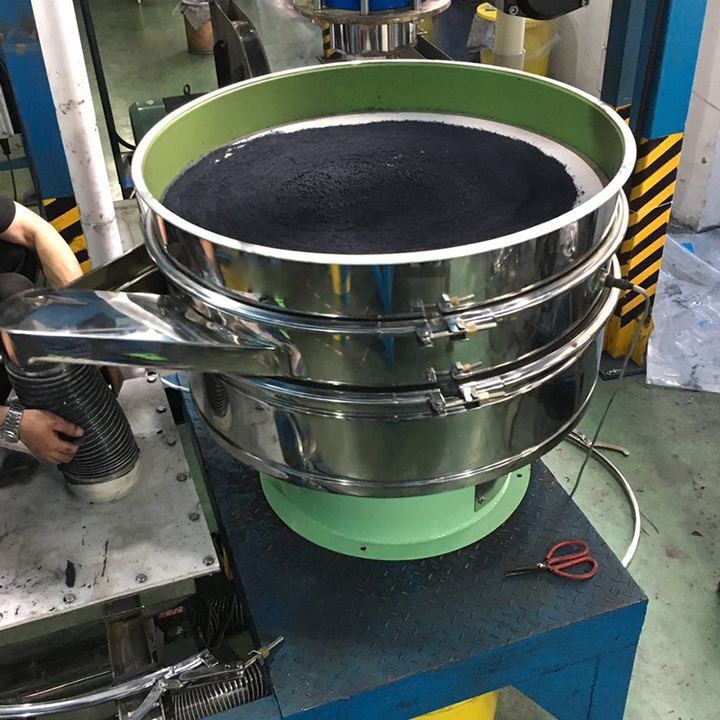

Ultrasonic vibrating sieve is a fine powder sieving machine with relatively perfect technology in vibrating sieve. For micro-powder grade materials, ultrasonic vibrating sieve extension machine has a good screening effect. In the production and processing of diamond micro-powder, the commonly used sieving machine is ultrasonic vibrating sieve. Since diamond micro-powder is an ultra-fine powder material, the screening effect of ordinary vibrating sieve is not as good as that of ultrasonic vibrating sieve wave vibrating sieve. Works well.

Diamond micropowder refers to diamond particles with a particle size of less than 36/54 microns, including single crystal diamond micropowder and polycrystalline diamond micropowder. Single crystal diamond powder is produced from artificial diamond single crystal abrasive grains, which are crushed and reshaped, and produced by a special process. It is a kind of ultra-fine abrasive with diamond powder. At present, it has been widely used in machinery, aerospace, optical instruments, glass, ceramics, electronics, petroleum, geology, and military industries. It is used for grinding and polishing cemented carbide ceramics, gemstones, optical glass Ideal material for high hardness materials. Generally, 0-0.5 micron diamond powder to 6-12 micron diamond powder is used for polishing; 10-15 micron to 22-36 micron is used for grinding; 12-22 micron is used for fine grinding.

Benefits of ultrasonic vibrating sieve for diamond powder

1. While achieving high-precision and high-mesh sieving, it can control a narrow particle size range.

2. It can be used in single-layer and multi-layer, and a set of intelligent ultrasonic generator uses three transducers at the same time.

3. The self-cleaning function of the screen mesh: more than 500 mesh screening, no mesh blockage, no screening efficiency attenuation.

4. Really solve the screening problems such as strong adsorption, easy agglomeration, high static electricity, high precision, high density and light specific gravity.

5. Ensure that the characteristics of the processed materials remain unchanged.

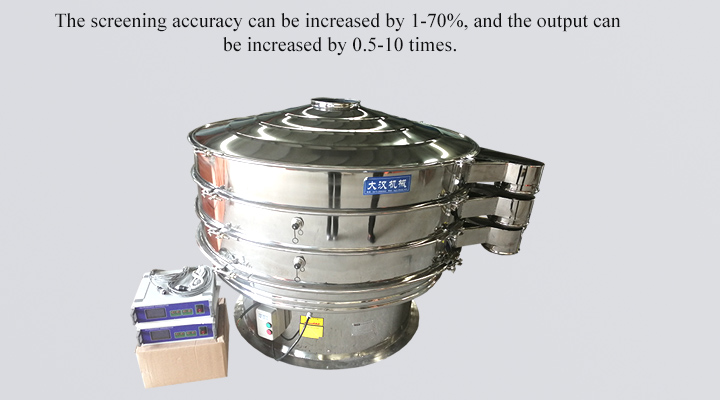

6. The screening accuracy can be increased by 1-70%, and the output can be increased by 0.5-10 times.

To discuss your specific requirements with an experienced sales engineer, please contact Dahan Machinery today.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.