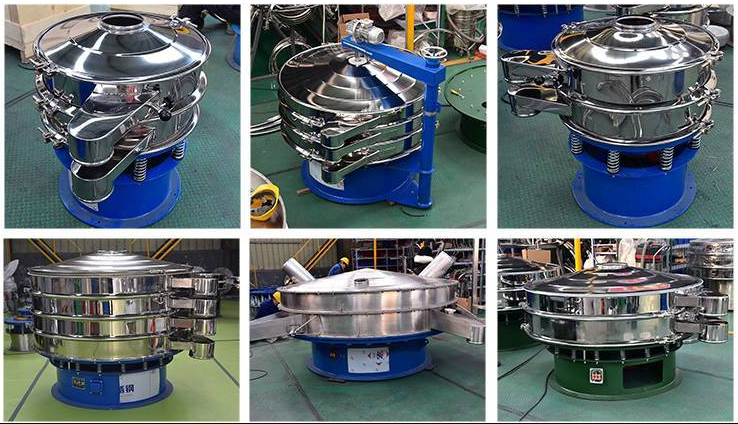

Ultrasonic vibrating sieve is a simple, practical, accurate and reliable screening system. It is an effective device to solve the problem of fine powder screening efficiency and precision. It can be widely used in industries such as pharmacy, metallurgy, chemical industry, mineral processing, food and other industries that require fine screening and filtration. Holes and other screening problems.

For customers who choose ultrasonic vibrating sieve for the first time, what aspects should they choose from? Is it the same as the selection method of other screening equipment? Dahan Machinery summarizes the following four points on the issues that customers care about :

1. Whether the material is suitable for ultrasonic vibrating sieve

When purchasing an ultrasonic vibrating sieve, you should choose it according to your own usage. The ultrasonic vibrating sieve has a very obvious screening effect on fine powder, but for some materials with coarser particle size, it is not as obvious as the ordinary vibrating sieve or linear vibrating sieve. It has no obvious effect on some materials with good fluidity and solid-liquid separation. The purchase of ultrasonic vibrating sieve needs to be based on your own needs. The so-called only suitable for yourself is correct. Before choosing this series of sieves, you should clarify the particle size, physical properties and output requirements of the material, and then combine the different sizes provided by Dahan Machinery. The throughput of the ultrasonic vibrating sieve is determined by the size and quantity of the equipment.

2. Select the material

Since the ultrasonic vibrating sieve is mostly used for the screening of fine materials below 600 mesh, the material requirements are correspondingly higher. The materials used in this series of equipment can be divided into two types: 304 stainless steel in contact with the material and stainless steel for the whole machine. For special materials to be screened, higher materials can also be used.

3. Yield and screening accuracy

As far as the round screen is concerned, the diameter of the screen surface and the effective screening area affect the output and screening accuracy of the screen machine. The screening area determines the screening accuracy (which can be increased by more than 95%), so please make a reasonable selection according to your production requirements when purchasing.

4. Are the accessories complete?

The main accessories of ultrasonic vibrating screen are: vibration motor, shock-absorbing spring, seal, screen, ultrasonic system. Be sure to pay attention when purchasing, because the seals and screens used by some vibrating screens are unqualified, so after a period of use, the seals will be broken and the screen will be damaged. When purchasing, please choose the ones supplied by regular manufacturers. Accessories.

In a word, the basic steps for selecting an ultrasonic vibrating sieve are the same as selecting ordinary screening equipment, that is, to determine the model according to the characteristics of the material, and to determine the size, mesh, and material of the vibrating screen according to the screening purpose and output requirements. But it should be noted that the biggest difference between ultrasonic vibrating sieve and other screening equipment is the "ultrasonic system".

Address:China,Yanjin county forest park gate to the west 1000 meters north road.