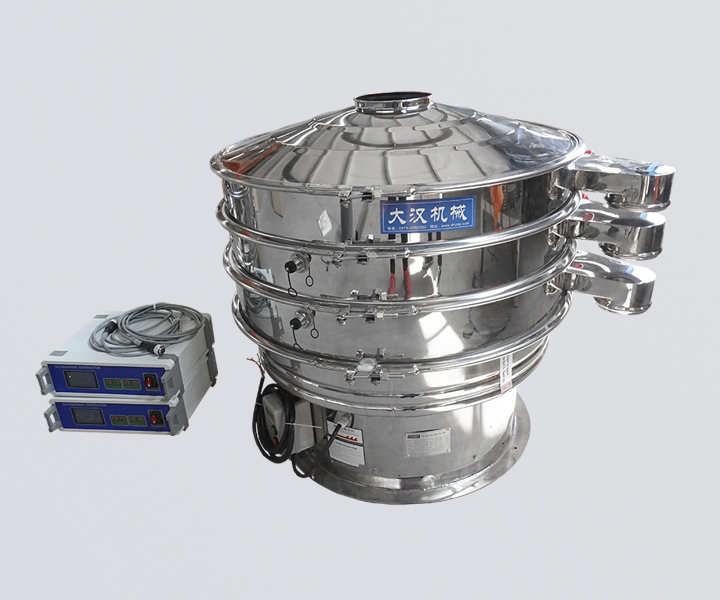

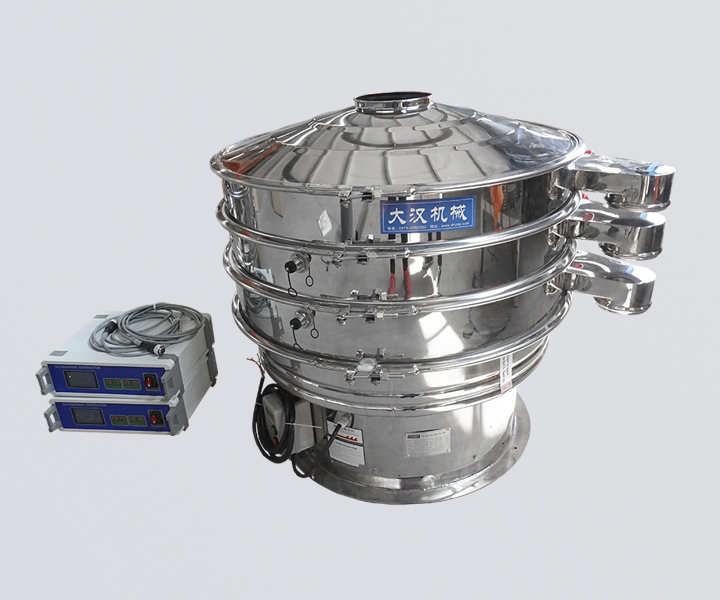

ultrasonic vibrating sieve

ultrasonic vibrating sieve ultrasonic vibrating sieve

ultrasonic vibrating sieve multi-layer ultrasonic vibrating sieve

multi-layer ultrasonic vibrating sieve single layer ultrasonic vibrating sieve

single layer ultrasonic vibrating sieve gas protection ultrasonic vibrating sieve

gas protection ultrasonic vibrating sieve

Prevents blinding and blocking when screening high fineness, strong adsorption, high static electricity, light specific gravity powders

![]()

![]()

![]()

Price:$800.00-$3,000.00/Set

Consult now and enjoy a 10% discount

Diameter: DHC400-1800mm

Mesh size: 60-635 mesh

Ultrasonic vibration frequency: 38KHz

Throughput: 0.2-5t/h

Transducer: Internal/External

Layer: 1-5 layer

Application:

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

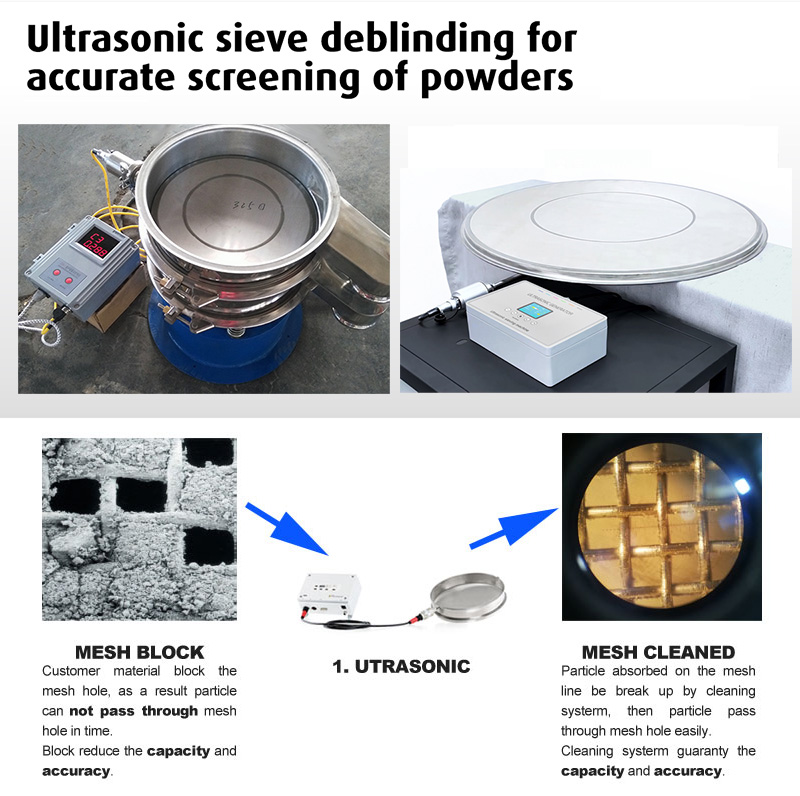

Ultrasonic vibrating sieve uses an ultrasonic transducer to apply high-frequency vibration to the screen. The frequency of the vibration breaks the surface tension, making the screen effectively frictionless, preventing too large and small particles from clogging or blocking the screen. Our ultrasonic system can Installed on new and existing vibrating sieve and screening machines, it can screen on finer meshes (as low as 20 microns) without clogging or clogging the apertures, and the sieving rate is increased by 5-20 times , Suitable for fine powder with strong adsorption, easy to agglomerate, high static electricity, high precision, high density, light specific gravity and other characteristics.

1. Ultrafine powder screening: Ultrasonic vibrating sieve really solves the screening problems of materials with strong adsorption, adhesion, viscosity, high static electricity, high density, ultrafine powder and other characteristics.

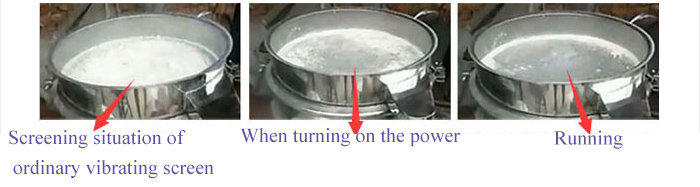

2. Solve the blockage of the screen: change the vibration frequency of the ordinary screen machine, the vibration frequency is 36000 times/min, so that the vibration frequency of the material in the same unit time increases, thereby increasing the number of times the material passes through the screen holes at the same time, and the material is easier to Through the screen, improve the permeability, so as to achieve the purpose of screening and cleaning the screen.

3. Cost reduction: Due to the elimination of screen clogging, the product quality remains consistent throughout the production process, and there is no need to stop the machine to clean the screen, reducing the risk of downtime and reducing production costs.

4. Increase the output: Since the screen will not be blocked, the screen can be cleaned without stopping, and the output can be increased by 0.5-10 times.

Ultrasonic vibrating sieve has been widely used in the screening of fine powders such as flour, graphite powder, rubber powder, quartz sand powder, metal powder, powder coating, phosphor powder, etc.

Ultrasonic vibrating sieve is a low-amplitude, high-frequency ultrasonic vibration wave (mechanical wave) installed on the screen of the traditional vibrating sieve. The ultra-fine powder accepts huge ultrasonic acceleration and improves the flatness of low-density powder in gravity settling (powder Light contact with the mesh port), slip effect, improve the retention or wedging of high-density metal in the mesh port, improve the adhesion effect of electrostatic powder, thereby improving the screening efficiency and screening quality, and make the surface of the screen The materials are always kept in a suspended state, thereby inhibiting the blocking factors such as adhesion, friction, flat drop, wedging, etc., and finally solved the screening problems of strong adsorption, easy agglomeration, high static electricity, high fineness, high density, and light specific gravity. To improve the sieving performance of ultra-fine particles.

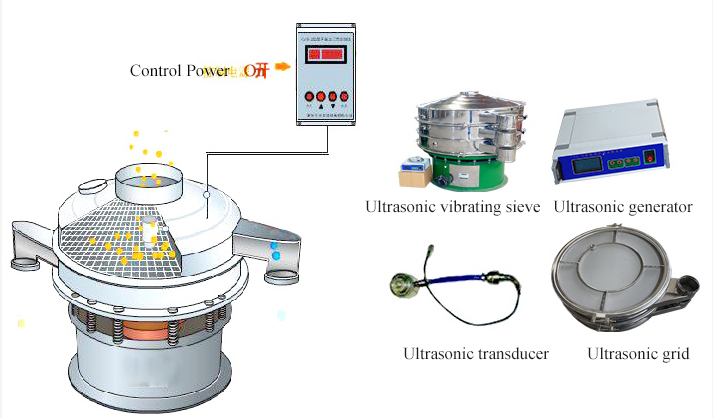

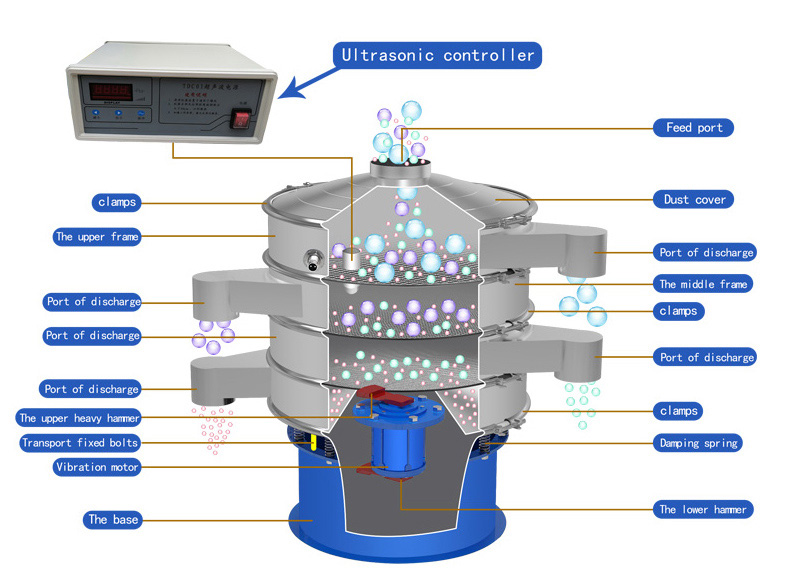

Ultrasonic vibrating sieve consists of the following: the ultrasonic generator or power supply, the ultrasonic transducer, and the screen mesh with energy conduction ring.

Ultrasonic generator – The ultrasonic generator for the vibrating sieve can either be UF08 or GTS30. Its specifications are as follows:

Power: 220V, 50/60Hz, Single-Phase

Power Consumption: 1A (Max.)

Output Frequency: 36KHz

Operating Mode: Continuous Mode / Pulse Mode

Box Dimension (WxHxD): 165 x 230 x 400mm

Transducer – The transducer has a stainless steel SS304 casing and has above screen position.

Resonance ring or conduction ring

Improves product quality

Apply the ultrasonic frequency directly to the mesh screen, effectively make the mesh wire frictionless and eliminate the clogging and blocking of the mesh, Screen powders on meshes as fine as 20 microns

Increase productivity and efficiency

With the ultrasonic deblinding system, there is little to no blockage in the sieve, allowing powder to pass through the sieve holes faster, and the sieving capacity is increased by 10 times

No dust

Ultrasonic vibrating sieve operates at high frequency and low amplitude, due to the low amplitude there is no dust during the sieving process

Reduce production downtime

Prevents clogging and reduces time spent cleaning grids

Reduce operating costs

Frictionless system eliminates damage caused by mechanical deblinding systems

Upgrade existing systems

Simple retrofit solution for all new and existing shakers and screening machines

Sieving heavy calcium powder

Ultrasonic vibrating sieve for graphite powder

| Model | Diameter (mm) |

Screening area (mm) |

Screen size (target) |

Layers | Input power (V/HZ) |

Ultrasound (model) |

Transducer (location) |

Frequency (KHz) |

Ultrasound (gear) |

Power (Kw) |

| DHC-400 | ⌀340 | 0.09 | 60-635 | 1-3 | Sieving machine 380/50 Ultrasonic sieving machine 220/50 |

400 | Built-in/External | 38KHz | Continuous 1-9 gears Pulse 2 gear |

0.25 |

| DHC-600 | ⌀540 | 0.23 | 600 | 0.55 | ||||||

| DHC-800 | ⌀730 | 0.42 | 800 | 0.75 | ||||||

| DHC-1000 | ⌀900 | 0.64 | 1000 | 1.1 | ||||||

| DHC-1200 | ⌀1100 | 0.95 | 1200 | 1.5 | ||||||

| DHC-1500 | ⌀1400 | 1.54 | 1500 | 2.2 | ||||||

| DHC-1800 | ⌀1700 | 2.27 | 1800 | 3 |

| Model | Test Material | Mesh Size | Vibrating Sieve | Ultrasonic Vibrating Sieve | |

|

|

||||

| ⌀1000 | Silicon carbide |  |

500 mesh | Cannot be sieved | 1500kg/h |

| ⌀1000 | Tungsten powder |  |

600 mesh | 15 minutes without sifting out fine powder | 30kg/h |

| ⌀1000 | Vitamin C powder |  |

100 mesh | 1kg/h | 120-150kg/h |

| ⌀600 | Pollen |  |

400 mesh | 15 minutes without sifting out fine powder | 15 minutes sieve |

| ⌀1000 | Cobalt powder |  |

400 mesh | 10kg/h | 300kg/h |

| ⌀1000 | NdFeB powder |  |

300 mesh | 32.2% sieve residue in 30 minutes | 6.9% sieve residue in 30 minutes |

| ⌀1000 | Gold steel sand powder |  |

300 mesh | Cannot be sieved | 1300kg/h |

| ⌀1200 | Antimony trioxide |  |

80 mesh | 700kg/h | 2000kg/h |

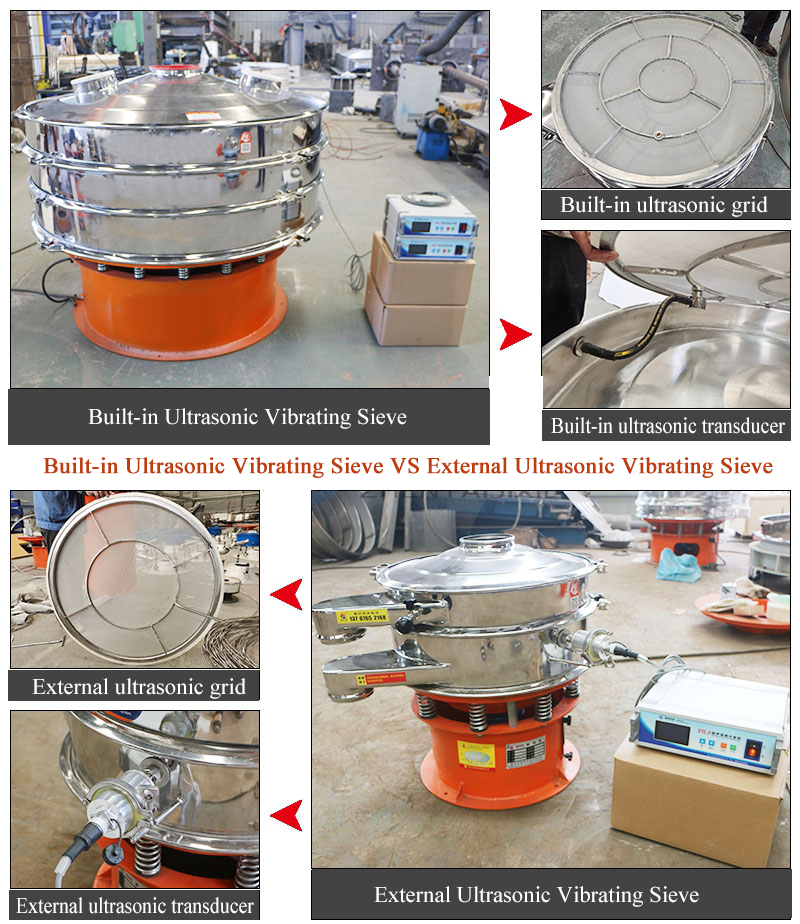

Ultrasonic vibrating sieve transducer plays an important role in the vibrating screen and is an indispensable part of the ultrasonic screening system. The installation of the transducer can be divided into two types: external type and built-in type.

Built-in ultrasonic vibrating sieve: the connector of the ultrasonic transducer is placed inside the sieve machine for connection, so that it can directly contact the material during work, and the cost is low. The price of the built-in system on the market is twice that of the external system.

External ultrasonic vibrating sieve: the ultrasonic transducer is installed outside the screen frame and extends to the edge of the grid, avoiding direct contact with the material, avoiding contamination of the material, in line with the hygiene standards of the food and pharmaceutical industries, low failure rate, and improved capacity.

In addition, our products can also be customized according to your requirements, such as the height of the screen machine, the length of the discharge port, the addition of dust removal ports, the addition of iron removers, material (carbon steel or stainless steel), the size of the feed port, airtight Sex and other special use environments and specific use conditions.

| Material | Proportion | Mesh | Processing method | Capacity (kg/hr IT/hr) |

Model |

| Glucose powder | 0.8 | 20 | Dry | 2000㎏ | DHC-1200-2S |

| Wheat flour | 1 | 250 | Wet | 3200 IT | DHC-1200-1S |

| flour | 0.6 | 24 | Dry | 1500㎏ | DHC-1000-1S |

| Rice flour | 0.5 0.8 | 100 | Dry | 300 ㎏ | DHC-1000-1S |

| Soy sauce | 1 | 100 | Wet | 6500 IT | DHC-1200-1S |

| Salt | 1.2 | 30/80 | Dry | 5000㎏ | DHC-1500-1S |

| Pollen | 0.4 | 12 | Dry | 100㎏ | DHC-1500-1S |

| Spices | 0.7 | 40/80 | Dry | 320㎏ | DHCC-800-2S |

| Coarse sugar | 1.2 | 12 | Dry | 8000㎏ | DHCC-1500-1S |

| Pineapple juice | 1 | 100 | Wet | 3000㎏ | DHCC-1000-1S |

| Skimmed milk powder | 0.57-0.7 | 24 | Dry | 3000㎏ | DHC-1200-1S |

| Whole milk powder | 0.57-0.8 | 12 | Dry | 1600㎏ | DHC-1000-1S |

| Rice bran | 0.5 | 16 | Dry | 500㎏ | DHC-800-1S |

| Powdered sugar | 0.5-0.8 | 100 | Dry | 200㎏ | DHC-800-1S |

| Corn starch | 0.6 | 40 | Dry | 1600㎏ | DHC-1000-1S |

| Mmedicine powder | 0.8 | 80 | Dry | 550㎏ | DHC-800-1S |

Xinxiang Dahan Machinery mainly produces ultrasonic vibrating sieve and original accessories supply, and provides material removal, screening and filtration solutions. To ensure that each part has no broken welding, missing welding, burrs, etc., the grid installation, outlet design and other details have standard design, avoid user losses caused by product quality, and comprehensively protect your rights and interests. Direct-selling manufacturers can effectively reduce the middle price difference and shorten the distance between users and manufacturers. On the basis of ensuring product quality, the price positioning of ultrasonic vibrating sieve is more reasonable and reduces the investment cost of users.

Q: What is the use of an ultrasonic vibrating sieve?

A: allows for easier separation of bulk powders such as metal powders, paints, chemicals or food powders. An ultrasonic frequency is passed through to the sieve mesh, causing it to vibrate. This prevents blinding, or blockage, thereby letting particles pass through the mesh more easily.

Q: What is the difference between ultrasonic vibrating sieve and vibrating sieve?

A: Ultrasonic vibrating sieve is equipped with an ultrasonic anti-blind device on the basis of vibrating sieve, so the mesh with self-cleaning function is not blocked, and there is no need to add anti-blocking devices such as bouncing balls. The screening accuracy and output will be higher than that of vibrating sieve.

Q: What kind of materials is suitable for screening ultrasonic vibrating sieve?

A: Suitable for sieving 500 mesh high-precision, highly absorbent, sticky, and easily agglomerated powder materials, with self-cleaning function and no blocking of the net.

Q: What are the models of ultrasonic vibrating sieve?

A: Conventional models are 600mm in diameter, 800mm in diameter, 1000mm in diameter, 1200mm in diameter, 1500mm in diameter, etc. Special models can also be customized according to the requirements of different users. For customization, please click on-line consultation.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address::China,Yanjin county forest park gate to the west 1000 meters north road.