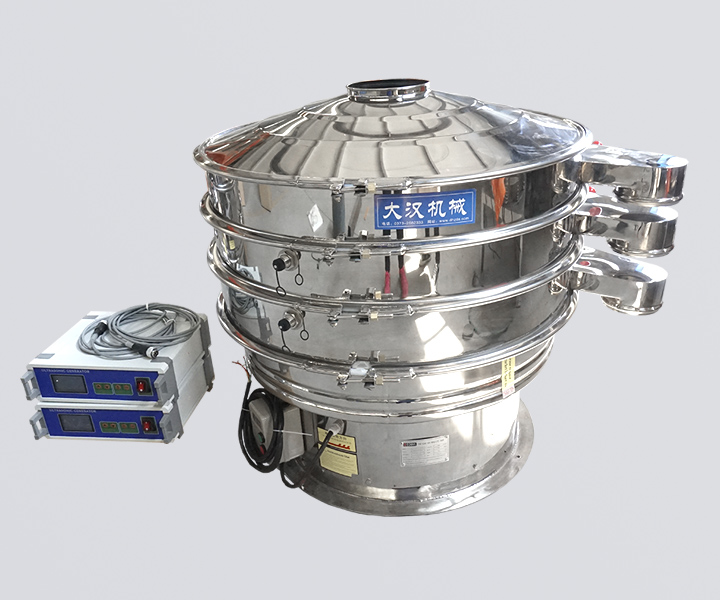

vibrating sieve

vibrating sieve circular vibrating sieve

circular vibrating sieve ultrasonic vibrating Sieve

ultrasonic vibrating Sieve plastic vibrating sieve

plastic vibrating sieve vbrating sieve with silo

vbrating sieve with silo

For high-capacity screening of powders and liquid slurries

![]()

![]()

![]()

Price:$800.00-$5,300.00/Set

Consult now and enjoy a 10% discount

Mesh Size:0-500 Capacity:100-5000kg/h1-5 layers

Type:Circular

Diameter:400-2000mm

Voltage:220v/380v as you need

Application:Powders, granules and liquids

Commitment:

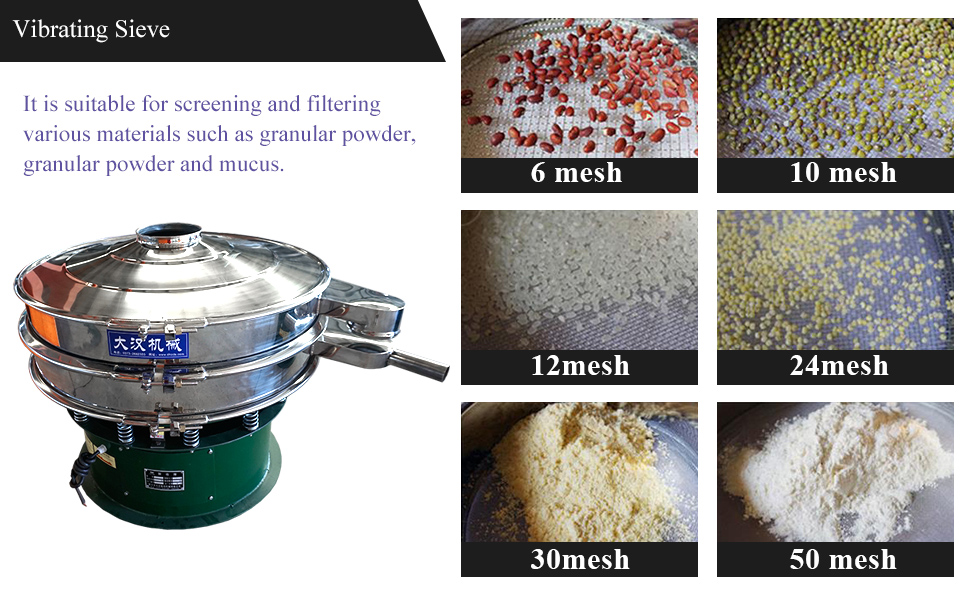

Vibrating sieve is mainly used for screening and impurity removal of powder, granular and liquid materials. The screening is as fine as 500 meshes and the filtration can reach 5 microns. The enclosed sanitary screener ensures the total containment of screened materials, 1-4 layers of screens can be added according to user requirements.

Dahan Vibrating Sieve has a variety of sizes and mesh options to choose from, which can be customized according to your specific screening and sieving requirements.

| Type | Rotary Vibrating Sieve | Ultrasonic Vibrating Sieve | Industrial Vibrating Sieve | Electric Vibrating Sieve |

|

|

|

|

|

| Application | Powder, granule, liquid | Prevent fine powder from clogging your mesh | Coarse sieve for powder and granules | Remove impurities in powder and liquid |

| Price | $800.00-$4,500.00 | $980.00-$4,300.00 | $600.0-$3,500.00 | $320.00-$600.00 |

| Model(mm) | DH400-2000 | DHC400-1800 | ZPS600-1500 | GLS450(Only) |

| Mesh(mesh) | 500 | 625 | 140 | 400 |

| Capacity(kg/h) | 100-5000 | 100-5000 | 3000-30000 | 400-1200 |

| Layer | 1~5 | 1~5 | 1 | 1 |

| Power(KW) | 0.25-3 | 0.18-2.2 | 0.18-0.75 | 0.188 |

vibrating sieve for flour

vibrating sieve for salt

vibrating sieve for soy milk filtration

Wide range of applications

Screen and remove excessive contaminants and impurities from powder and liquid slurries

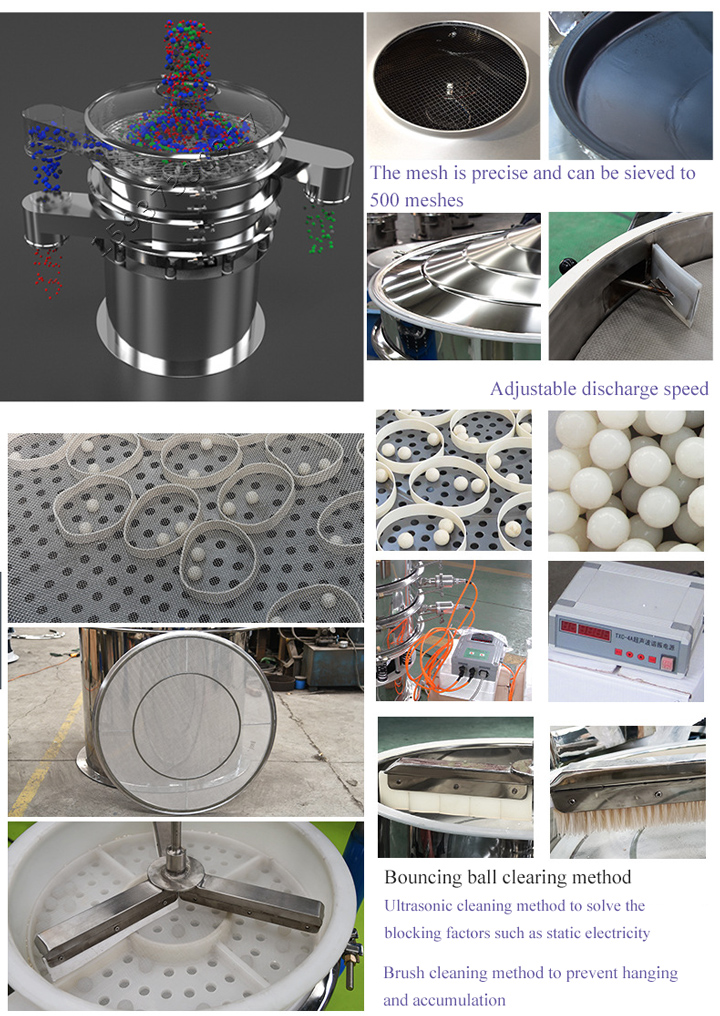

Highest precision

The sieving is as fine as 500 mesh or 0.028mm, which can prevent materials from blocking your mesh

Maximum capacity

The classification of 5 different materials can be realized in one operation

Remove dust

Fully enclosed structure can ensure that the material is scattered during the screening process

Reduce noise

The rubber sealing system of the sieve can suppress mechanical noise and ensure quiet operation.

Easy mesh replacement

Vibrating sieve is equipped with a convenient screen changer, which enables the operator to work smoothly.

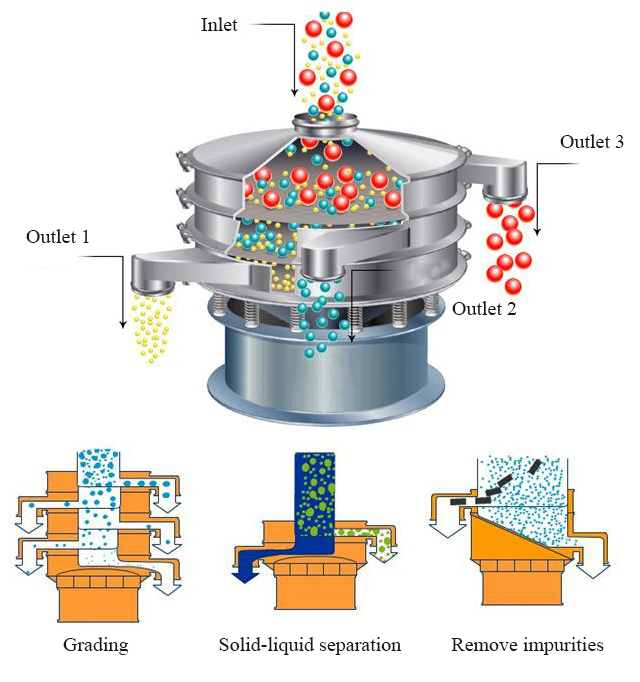

The material enters the vibrating sieve through the inlet. According to different material screening requirements, the material passes through 1-5 layers with different mesh screens. In this process, the cleaning device (bouncing ball) is located under the screens of each layer. ) Constantly hitting the screen through frequency vibration, so that the materials on the screen can be screened through the screen smoothly, and effectively solve the problem of material blockage. The materials of different meshes pass through the screens of the corresponding meshes in each layer and then fall on each layer. The discharge port is discharged to finally achieve the purpose of screening and removing impurities or filtering and grading.

| Model | Diameter(mm) | Feeding Size(mm) | Frequency(RPM) | Layers | Power(kw) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 |

| DH-600 | 600 | 0.25 | |||

| DH-800 | 800 | 0.55 | |||

| DH-1000 | 1000 | 0.75 | |||

| DH-1200 | 1200 | 1.1 | |||

| DH-1500 | 1500 | 1.5 | |||

| DH-1800 | 1800 | 2.2 |

Common applications of Vibrating sieve include:

1.Sieving, peeling, sieving and classification of dry bulk solids

2.Separation of solids and liquids

3.Classification and sorting

4.Protective screening

5.Superfine, fine, medium and coarse screening

6.Dust removal

7.Super long and super large material screening

Q: What are the uses of an industrial vibrating sieve?

A: It is mainly used to screen out oversized, clumps and foreign objects from liquids and powders to improve product quality.

Q: What are the uses of an industrial vibratory sieve?

A: In linear machines, the back and forth motion allows for powders to move linearly during the sieving process and are not typically used for liquid applications. circular vibrating sieves use a circular vibratory motion and are suited to both liquid and powder applications.

Q: What is the real delivery time of your factory?

A: 7 to 10 working days for general series products, meanwhile, customized products would need 20 days to 40 days based on different situations.

Q: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of DH for most of our customers at home or abroad.However, we do recognized that there do have small amount of the product which may got faulty or damaged for different reasons.

Q: How do your after-sale service work if the product got damaged?

A: In the gurantee time 12 months, our general aftersale serve.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.