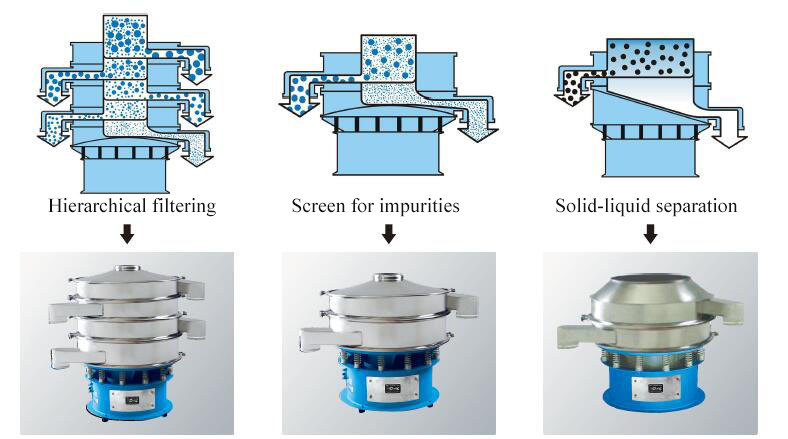

Ultrasonic vibrating sieve is an ultrasonic screening system added on the basis of ordinary vibrating sieve, which solves the screening problems such as strong adsorption, easy agglomeration, high static electricity, high precision, high density, light specific gravity, etc., in order to improve the ultra-fine particles Therefore, the ultrasonic vibrating screen is especially suitable for users of high-quality, fine powder.

Ultrasonic vibrating sieve working principle

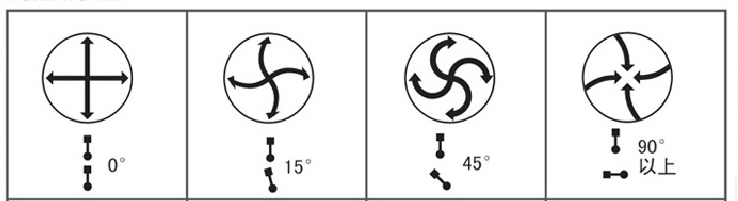

The working principle of ultrasonic vibrating sieve is to convert 220V, 50Hz or 110V, 60Hz electric energy into 18KHz high-frequency electric energy, input the ultrasonic transducer, and turn it into 18KHz mechanical vibration, and the frequency band output by the CNC power supply is transmitted to the The surface of the screen mesh is 360,000 times/min. When the material is screened, the force of the three-dimensional movement of up and down, horizontal and inclined on the screen surface is also subjected to the high frequency and low amplitude force of the ultrasonic system on the screen surface, so that the ultrasonic vibrating sieve achieves the purpose of sieving and net cleaning. Compared with ordinary vibrating sieve, the screening accuracy can be increased by 1-70%, and the output can be increased by 0.5-10 times.

Ultrasonic vibrating sieve working steps

The working steps of ultrasonic vibrating sieve are briefly introduced as follows:

Particle material feeding: Put the particle material to be screened into the screening area of ultrasonic vibrating sieve.

Ultrasonic vibrator function: The ultrasonic vibrator generates high-frequency ultrasonic waves and transmits them to the screen.

Ultrasonic waves act on particles: Ultrasonic waves make particles vibrate slightly on the screen, destroying the adhesion between particles.

Screening: Particles are screened on the screen under the action of ultrasound, and fine particles pass through the screen, while larger particles remain on it.

Cleaning the screen: Ultrasonic waves prevent the screen from being blocked and keep it clean.

Particle separation: Particles of different sizes are effectively separated.

Output materials: The final materials are collected, packaged or processed as needed.

The above is an introduction to the working principle of ultrasonic vibrating sieve. If you want to know more about ultrasonic vibrating sieve, please contact us

Address:China,Yanjin county forest park gate to the west 1000 meters north road.