Ultrasonic screen

Ultrasonic screen Stainless steel ultrasonic screen

Stainless steel ultrasonic screen Ultrasonic vibrating screen

Ultrasonic vibrating screen Carbon steel ultrasonic screen

Carbon steel ultrasonic screen 4 layers ultrasonic screen

4 layers ultrasonic screen

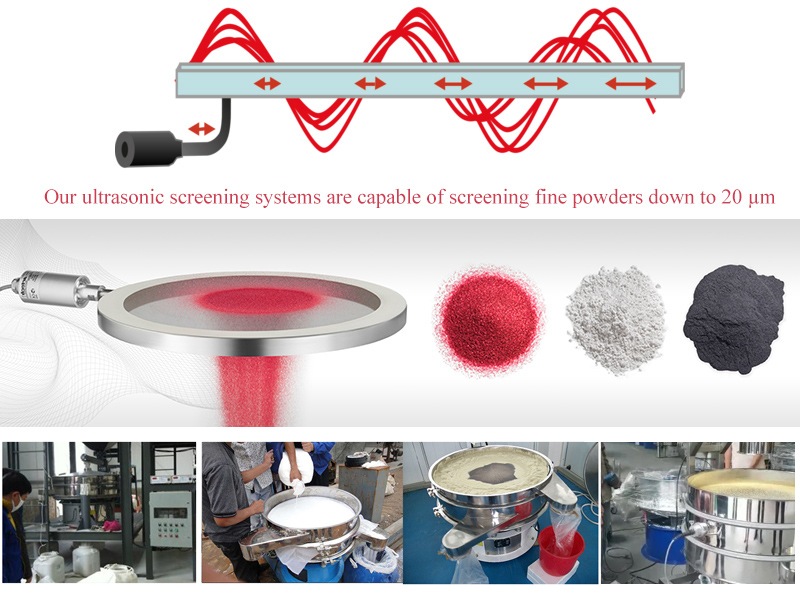

Sieving on finer meshes (down to 20 microns) without any blocking or blinding of the aperture

![]()

![]()

![]()

Price:$800.00-$3,000.00/Set

Consult now and enjoy a 10% discount

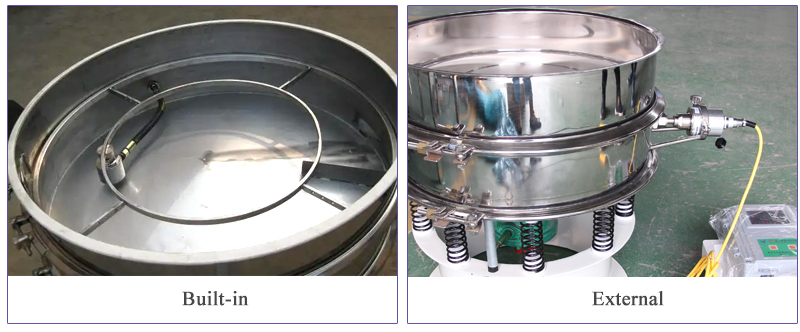

Type: Built-in/External

Vibration frequency: 36,000 times per second

Mesh size: 80-600 mesh

Capacity: 100-5000kg/h

Diameter: 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm

Layers: 1-5 layers

Motor power: 0.18-2.2KW

Application:suitable for various materials with high electrostatic, high fineness, strong adsorption, easy agglomeration, high density and light specific gravity

Commitment:

Ultrasonic screen, also called ultrasonic sieve, ultrasonic screening machine, is a vibrating screen equipment that uses ultrasonic vibration to improve fine powder screening. In an ultrasonic screen, high-frequency ultrasonic vibrations are applied directly to the screen mesh, causing the screen to vibrate at a frequency higher than the standard vibrating screens. This ultrasonic vibration helps to break the static bond between the particles and the screen mesh, preventing clogging and improving the sieving accuracy and efficiency.

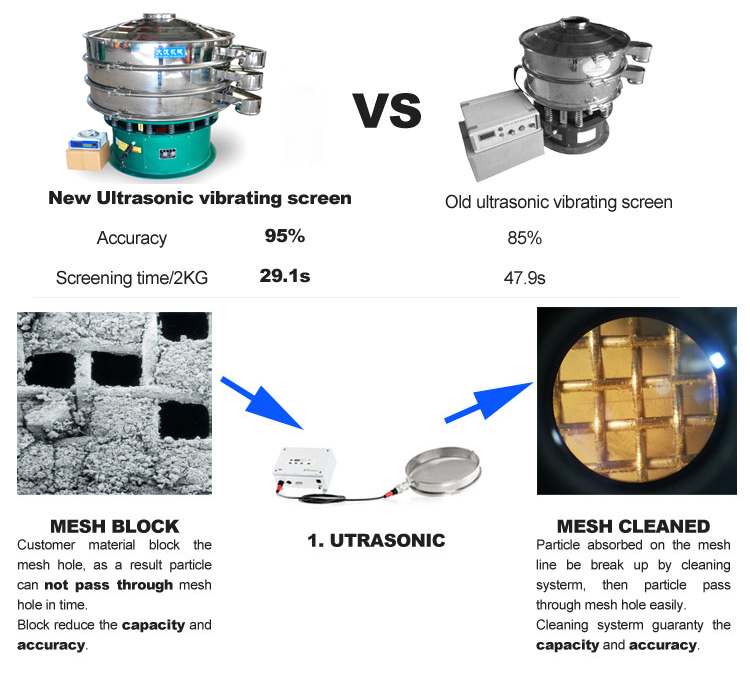

Ultrasonic screen can separate 20μm (#635 mesh) fine powder, and the sieve holes are not blocked or clogged. At the same time, it increases production and reduces the number of cleaning times. Compared with ordinary vibrating screens, the screening accuracy is improved by 1-70%, and the output can be increased by 0.5-10 times. It solves the problems of strong adsorption, static electricity, strong viscosity, high density, and solves the problem of ultrafine powder screening.

Ultrasonic screen makes it easier to separate bulk powders such as metal powders, paints, chemicals or food powders. Ultrasonic frequencies pass through the screen, causing it to vibrate, which prevents blinding or clogging, allowing particles to pass through the mesh more easily.

1. Ultrafine powder screening: It really solves the screening problems of materials with strong adsorption, adhesion, viscosity, high static electricity, high density, ultrafine powder and other characteristics.

2. Solve the blockage of the screen: change the vibration frequency of the ordinary screen machine, the vibration frequency is 36000 times/min, so that the vibration frequency of the material in the same unit time increases, thereby increasing the number of times the material passes through the screen holes at the same time, and the material is easier to Through the screen, improve the permeability, so as to achieve the purpose of screening and cleaning the screen.

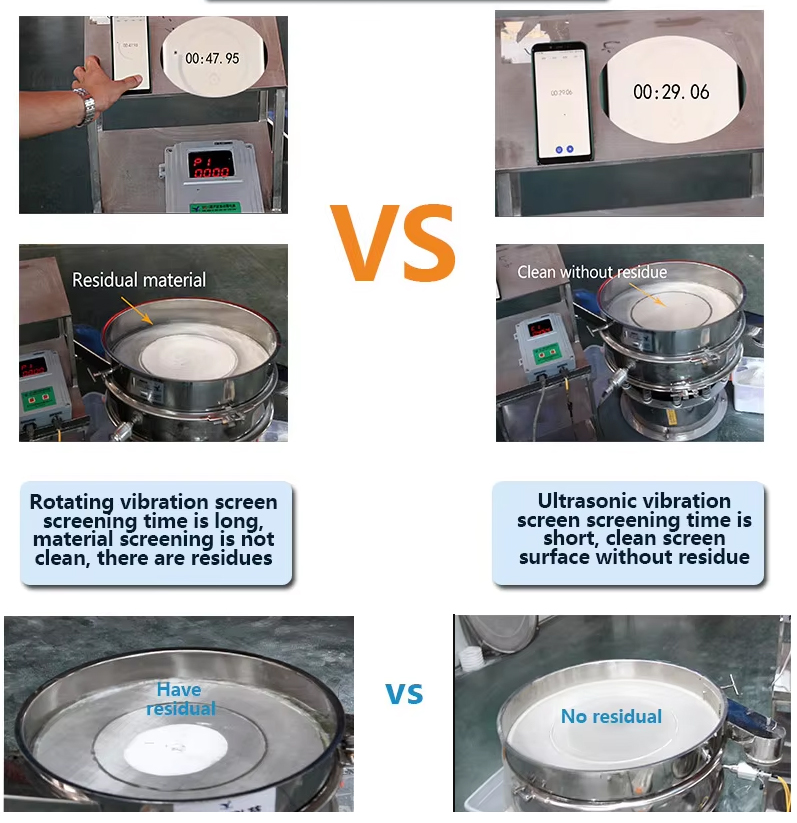

3. Cost reduction: Due to the elimination of screen clogging, the product quality remains consistent throughout the production process, and there is no need to stop the machine to clean the screen, reducing the risk of downtime and reducing production costs.

4. Increase the output: Since the screen will not be blocked, the screen can be cleaned without stopping, and the output can be increased by 0.5-10 times.

Ultrasonic screen has a better effect on materials that are difficult to sieve such as strong adsorption, easy agglomeration, high static electricity, high fineness, high density, and light specific gravity. It is suitable for 400 mesh, 500 mesh and 600 mesh fine materials, such as graphite powder, Diamond, glass powder, silica-alumina powder, slurry, white latex, alumina, quartz sand, lithium battery cathode material, metal powder, phosphor powder, titanium powder, trace mineral powder, sulfur powder, high nickel ternary cathode material, ring Oxygen powder, traditional Chinese medicine powder, catalyst, lithium battery powder, stainless steel metal powder, chili powder, diamond, matcha powder, etc.

| Materials | Screening method | Sieve mesh (mesh/inch) |

Output (kg/h) |

| Flour | dry | 16, 20 | 800 |

| Granulated sugar | 4, 20 | 2000 | |

| Pharmaceutical powder | 80, 100, 150 | 1400 | |

| Resin powder | 40, 60, 80 | 1000 | |

| Grinding powder | 40, 60, 80 | 1200 | |

| Pigment powder? | 40, 60, 240 | 4000 | |

| Iron powder | 20 | 2500 | |

| Copper powder | 60, 80, 120 | 2000 | |

| Graphite | 80 | 1400 |

Ultrasonic screen is an ultrasonic deblinding system added on the basis of ordinary vibrating screen. It can input 220V, 50Hz or 110V, 60Hz electric energy into the ultrasonic transducer, and convert it into 36KHz mechanical vibration. High-frequency vibration, the vibration frequency can reach 36,000 times per second, which can make the fine powder material form a micro-suspended state on the screen, and can pass through the screen faster without generating static electricity and sticking to the screen. At the same time, it achieves the effect of screening and cleaning the screen.

Suitable for sieving of 20-300μm mesh

The high-frequency vibration makes the fine materials in contact with the screen pass through the screen quickly, and the penetration rate of the screen is improved. Our ultrasonic screening systems enable you to screen powders more efficiently with separation cuts from 20 µm to approx. The screening accuracy can be improved by 1- 70%.

Prevent mesh clogging

The ultrasonic system applies a high-frequency vibration to the sieve mesh. The frequency of the vibration breaks the surface tension, making the stainless-steel mesh effectively friction-free and preventing oversized and undersized particles from blinding or blocking the mesh screen.

Increase throughput

Ultrasonic sieving increases the sieving capacity by 10 times by making the powder pass through the sieve holes faster.

Upgrade existing systems

Simple retrofit solution for all new and existing shakers and screening machines.

Single/Multilayer Screening

Provides up to 5 levels of classification in one operation, and one or more ultrasonic transducers can be added to one screen to enhance the screening effect.

Reduce production downtime

Preventing clogging while reducing the time it takes to clean the screen, the frictionless system eliminates damage caused by mechanical deblinding systems.

Ultrasonic screens improve screening accuracy and efficiency through high-frequency ultrasonic vibrations. They are particularly suitable for fine powders and difficult-to-handle granular materials, and can effectively prevent clogging. Ordinary screens are suitable for general granular materials, but are less effective when handling fine or easily clogged powders.

Compared with ordinary screens, ultrasonic screens can usually provide higher screening accuracy and efficiency in fine powders and difficult-to-handle granular materials, and can effectively prevent clogging.The following table is a comparison of the two in screening different powders:

| Model | Test Material | Mesh Size | Vibrating Sieve | Ultrasonic Vibrating Sieve | |

|

|

||||

| ⌀1000 | Silicon carbide |  |

500 mesh | Cannot be sieved | 1500kg/h |

| ⌀1000 | Tungsten powder |  |

600 mesh | 15 minutes without sifting out fine powder | 30kg/h |

| ⌀1000 | Vitamin C powder |  |

100 mesh | 1kg/h | 120-150kg/h |

| ⌀600 | Pollen |  |

400 mesh | 15 minutes without sifting out fine powder | 15 minutes sieve |

| ⌀1000 | Cobalt powder |  |

400 mesh | 10kg/h | 300kg/h |

| ⌀1000 | NdFeB powder |  |

300 mesh | 32.2% sieve residue in 30 minutes | 6.9% sieve residue in 30 minutes |

| ⌀1000 | Gold steel sand powder |  |

300 mesh | Cannot be sieved | 1300kg/h |

| ⌀1200 | Antimony trioxide |  |

80 mesh | 700kg/h | 2000kg/h |

| Model | Diameter (mm) |

Screening area (mm) |

Screen size (target) |

Layers | Input power (V/HZ) |

Ultrasound (model) |

Transducer (location) |

Frequency (KHz) |

Ultrasound (gear) |

Power (Kw) |

| DHC-400 | ⌀340 | 0.09 | 60-635 | 1-3 | Sieving machine 380/50 Ultrasonic sieving machine 220/50 |

400 | Built-in/External | 38KHz | Continuous 1-9 gears Pulse 2 gear |

0.25 |

| DHC-600 | ⌀540 | 0.23 | 600 | 0.55 | ||||||

| DHC-800 | ⌀730 | 0.42 | 800 | 0.75 | ||||||

| DHC-1000 | ⌀900 | 0.64 | 1000 | 1.1 | ||||||

| DHC-1200 | ⌀1100 | 0.95 | 1200 | 1.5 | ||||||

| DHC-1500 | ⌀1400 | 1.54 | 1500 | 2.2 | ||||||

| DHC-1800 | ⌀1700 | 2.27 | 1800 | 3 |

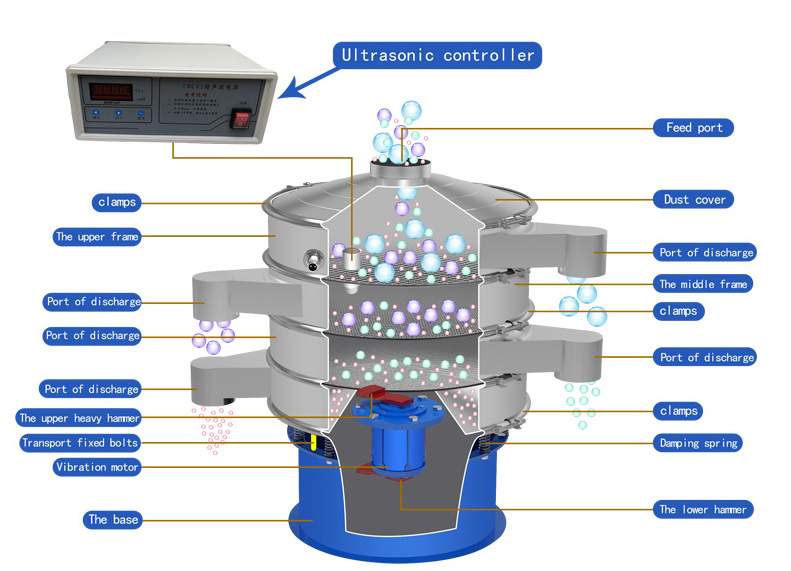

1. Ultrasonic transducer: This structure is the characteristic structure of the ultrasonic vibrating screen, which has the function of converting low-frequency electric energy into high-frequency and low-amplitude ultrasonic waves.

2. Ultrasonic special network frame: This network frame structure is equipped with a resonance ring to convert the ultrasonic wave into a mechanical wave with high vibration frequency and low amplitude, and then transmit it to the surface of the screen. Using a special double-ring structure, it will give full play to the ultrasonic effect after measurement and design, and reasonably distribute the amplitude in the entire area of the screen, so that the ultrasonic energy can be evenly transmitted on the entire screen surface.

3. Ultrasonic power supply: This structure controls the output power and frequency of ultrasonic waves can be adjusted.

4. Screen, screen frame, vibrator, and base: The screen is woven, suitable for 10 mesh to 635 mesh, and the structure of the screen frame, vibrator, and base is similar to that of an ordinary screen.

Built-in ultrasonic transducer: The ultrasonic transducer joint is placed in the middle of the grid of the ultrasonic screen, which can directly contact the material during operation, and the cost is low. At present, the price of the built-in system on the market is twice as low as that of the external system.

External ultrasonic transducer: The ultrasonic transducer is installed outside the screen frame and extends to the edge of the mesh frame. Because it avoids direct contact with materials and avoids contamination of materials, it meets the hygiene standards of the food and pharmaceutical industries, and the failure rate is low and improves. capacity.

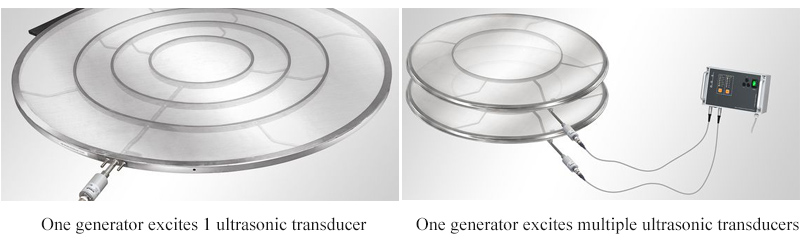

Ultrasonic screens allow simultaneous excitation of multiple ultrasonic transducers using a single generator. Due to the change in frequency, even screens with different resonance characteristics can be excited simultaneously.

1.For large screen frames, a single large or multiple waveguide rings can be processed using multiple ultrasonic transducers excited by one generator.

2.Even individual screen frames, for example in screening machines with two or more screen decks, can be activated simultaneously.

The ultrasonic system of an ultrasonic screen usually includes the following main parts:

1. Ultrasonic vibrator: a device used to generate high-frequency ultrasonic vibrations, usually composed of an ultrasonic generator and a vibrator.

2. Ultrasonic sensor: used to monitor the propagation and reflection of ultrasonic waves to ensure the normal operation and propagation of ultrasonic waves.

3. Ultrasonic transmission device: used to transmit ultrasonic waves to the screen or screen frame to achieve the screening of granular materials.

4. Ultrasonic generator: an electronic device used to generate ultrasonic waves, responsible for providing an energy source for ultrasonic vibrations.

5. Control system: used to control the working state of the ultrasonic system, including adjusting the frequency, amplitude and other parameters of ultrasonic vibrations to achieve accurate screening of granular materials.

More ultrasonic screen application fields are: 400 mesh, 500 mesh, 600 mesh sieving silicon carbide material, alloy powder, molybdenum powder, stainless steel plate powder, tungsten powder, nickel powder, cobalt powder, electrostatic powder, ash calcium, butyl mitone Powder, malt powder, ribavirin, instant coffee, magnetic induction powder, battery cathode material, laser powder, etc.

| The name of material | Mesh | The capacity of Common vibrating screen (kg/h) | The capacity of Ultrasonic vibrating screen (kg/h) | The model of machine |

| Phosphor | 500 | 90 | 300 | φ800 |

| Zinc powder | 325 | 68 | 300 | φ800 |

| seasoning powder | 60 | 500 | 1200 | φ1000 |

| Resin powder | 200 | 340 | 745 | φ1000 |

| Sweet potato starch | 200 | 400 | 1500 | φ1000 |

| lron powder | 100 | 96 | 300 | φ800 |

| Kaolin | 200 | 38 | 200 | φ1000 |

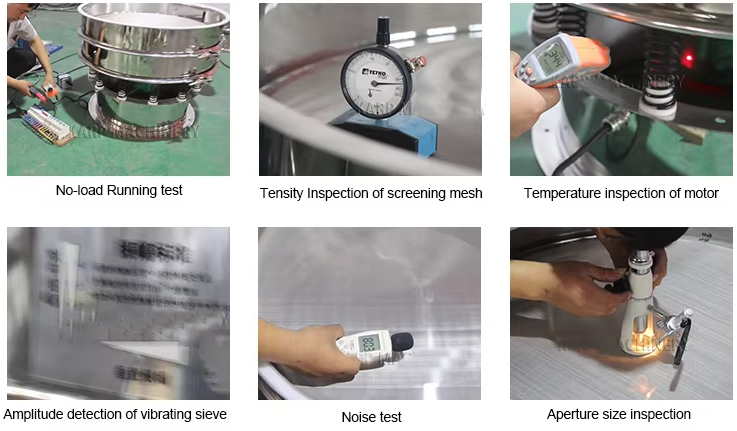

Xinxiang Dahan Vibration Machinery Co., Ltd. is an ultrasonic vibrating screen manufacturer integrating R&D, production and sales. It has been 12 years since our establishment. The manufacturer has obtained ISO9001 and EU CE certification, and has successfully served more than 80 countries and regions around the world. user.

Dahan ultrasonic screen can be made of carbon steel and stainless steel according to the screening materials. The models are complete, and non-standard designs can be customized according to user requirements.

The product will be shipped within 24 hours after being assembled, and if there is a performance problem within 30 days after the user signs it, it can be returned for free. It provides 1-year warranty, lifetime maintenance, original supply of product accessories and other services.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.