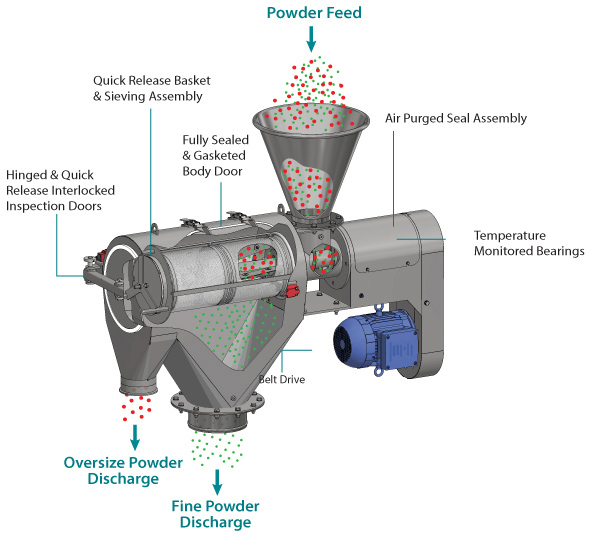

The airflow sieving machine is different from the vibrating screen. It uses the centrifugal force generated by the wind as the screening power to make the powdery material pass through the screen in the form of impact. According to the different forms, there are horizontal airflow sieving machine and vertical airflow sieving machine. There are two types of machines. The volume and output of the horizontal airflow sifter are smaller than the vertical airflow sieve, but the price is relatively lower than the vertical airflow sieve. The horizontal airflow sieve does not need to purchase other supporting devices.

Airflow sieving machine, also known as air sieving machine or cyclone sieving machine, are used to separate dry powders into different particle size fractions according to particle size and density. Following are some main features of airflow sieving machine:

1. Safety screening: remove foreign matter and sundries before the product enters the production process, can be used to remove impurities in a large amount of powdery materials, remove coarse particles or powdery materials from fine powders, and ensure product quality before filling.

2. Particle separation: It is used to separate dry powder into different particle size grades according to the size and density of particles. The machine uses a combination of air flow and centrifugal force to separate particles into fractions, typically in the range of 40 µm to 5 mm.

3. Dust removal: It can remove dust and other small particles in the dry powder to improve the quality and safety of the final product.

4. Deagglomeration: It can be used to break up the agglomerated particles, improve the fluidity and handling of the powder, and the strong wind impact can break up the agglomerated materials to a certain extent, making the powder finer and the screening efficiency higher.

Airflow sieving machine for metal powder

Airflow sieving machine for calcium hydroxide powder

1. High precision and high efficiency: Due to its unique design, the combination of airflow and centrifugal force is used to separate particles according to their size and density, so as to achieve high precision and high efficiency of particle separation, and the screening efficiency can reach 85-95%. , the residue on the sieve is basically 0 (it is difficult for ordinary sieving machines).

2. Wide range of applications: wide range of applications, including particle size classification, particle separation, powder dust removal, etc.

3. Not easy to stick to the screen: the rotating paddle helps to separate the agglomerated products and prevents the screen from sticking.

4. Environmental protection: it can operate at a very low noise level, and prevent dust leakage through dust-proof components to protect the safety of operators.

5. Minimal product loss: Minimize product loss during the screening process, thereby increasing yield and reducing waste.

6. High throughput: It can process a large amount of materials at a high throughput rate, suitable for industrial-scale production, and the output is 5-10 times that of ordinary vibrating screens.

Part of the material model recommendation table (for reference only)

| Material | Typical Capacity | Material | Typical Capacity |

| COCOA POWDER | 1-70 TPH | CALCIUM STEARATE | 1-30TPH |

| FISH MEAL | 1-40 TPH | EXPANDED SILICA | 0.5-6 TPH |

| FLOUR | 1-60 TPH | HYDRATED ALUMINA | 1-30 TPH |

| GROUND COFFEE | 1-30 TPH | IRON OXIDE | 1-40 TPH |

| LACTOSE | 5-300 GPM | LATEX | 5-200 GPM |

| (20-1850 LPM) | (20-900 LPM) | ||

| MILK POWDER | 1-30 TPH | PAPER FIBER | 5-400 GPM |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.