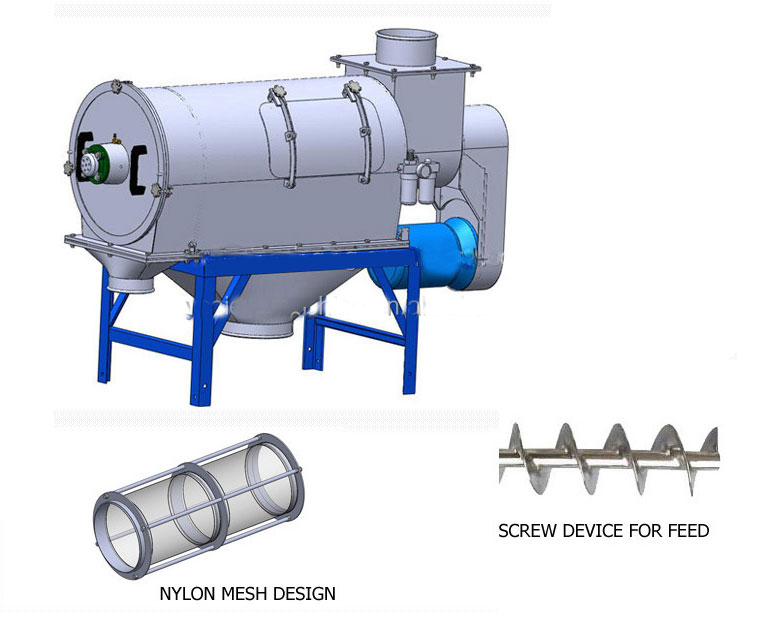

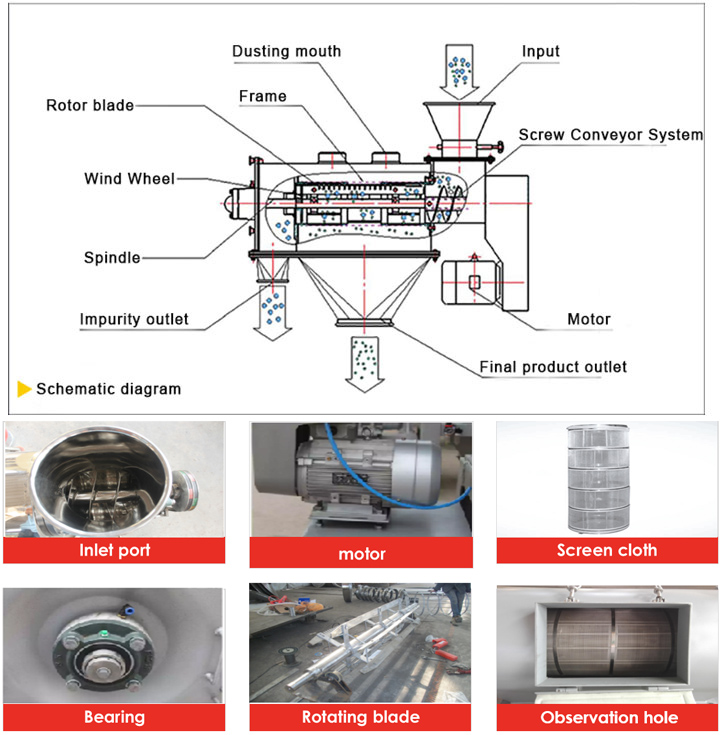

The Airflow sifter machine separates particles of two different sizes by using centrifugal force. The smaller materials pass through the static cylindrical screen through the rotating blades, while the oversized particles move along the screen to the outlet at the end of the equipment. The centrifugal force generated by the blades also Ideal for breaking up agglomerates and agglomerated powders so they can pass through the screen and increase throughput, the paddles are mounted on a cantilever shaft, eliminating the need for additional bearings, allowing for easy cleaning and quick screen changes. Since the airflow sifter machine adopts airflow atomization of raw materials into monomers to solve the fine powder screening problems of adhesion, high static electricity, and easy agglomeration, it can improve the purity of the product and solve the problems that are easy to occur when ordinary vibrating screens sieve fine powder. Problems such as flying dust.

Airflow sifter machine is suitable for ultra-fine powder with many fibers, high viscosity, light specific gravity, easy to generate static electricity and block the mesh, which solves the problem that ordinary sifter machine cannot sieve. It mainly has the following three functions:

1. Provide material size classification by screening and separating materials that do not meet the required size

2. Screen materials to remove unwanted materials and reduce contamination risk

3. Depolymerize the agglomerated powder material

Airflow sifter machine abandons the operating principle of gravity potential energy, and uses air as the carrier, and the operating principle of kinetic energy as work. After the material is mixed with air through the negative pressure airflow, it enters the middle of the wind wheel of the sieve machine, exerts enough centrifugal force through the blades of the wind wheel, sprays the barrel-shaped screen through the net, and collects through the volute. Oversized materials cannot pass through the screen, and are discharged from the automatic slag discharge port, so as to achieve the purpose of rapid screening.

1. It can continuously sieve powdery materials with a fineness range of 80-500 mesh. The sieving efficiency is above 95%, and the dust content in the air is less than 10mg/m3.

2. The sieve penetration rate can reach 85-95%, non-stick net, no blockage, precise sieving fineness, no super mixing phenomenon, and 0 sieve residue (difficult to achieve with ordinary vibrating sieves).

3. The screening efficiency is high, which can reach more than 95%, and the output can reach 5-10 times or higher than that of ordinary vibrating screens.

4. The screen is installed vertically without load and has a longer service life.

5. Low noise, low power consumption, continuous operation, no dust pollution.

6. It can be used in conjunction with various mills and wind roads.

7. The equipment is exquisitely designed, durable and easy to maintain.

| Model | Material | Power | Application |

| WQS18-65 | Q235A | 2.2KW | Screening below 500 mesh |

| SUW304 | |||

| WQS30-100 | Q235A | 4KW | |

| SUW304 | |||

| WQS50-130 | Q235A | 5.5KW | |

| SUW304 |

Airflow sifter machine and gas-solid separation and dedusting device form a closed-circuit screening system. The host machine is an airflow sifter machine. The airtight casing of the sieve body is equipped with a vertical cylindrical screen. The inside of the screen has a circular wind wheel, which is driven by a motor mounted on the base. There is a slag outlet at the bottom of the bucket and coarse screen, and the motor and the main shaft are connected by a belt; the lower opening of the wind wheel hopper forms a feeding gap. The gas-solid separation and dust removal device is composed of an induced draft fan, a settling chamber and a dust removal bag. The air flow screen and the separation and dust removal device are connected by a plastic corrugated hose.

| Material | Typical Capacity | Material | Typical Capacity |

| COCOA POWDER | 1-70 TPH | CALCIUM STEARATE | 1-30TPH |

| FISH MEAL | 1-40 TPH | EXPANDED SILICA | 0.5-6 TPH |

| FLOUR | 1-60 TPH | HYDRATED ALUMINA | 1-30 TPH |

| GROUND COFFEE | 1-30 TPH | IRON OXIDE | 1-40 TPH |

| LACTOSE | 5-300 GPM | LATEX | 5-200 GPM |

| LACTOSE | 20-1850 LPM | LATEX | 20-900 LPM |

| MILK POWDER | 1-30 TPH | PAPER FIBER | 5-400 GPM |

| NON-DAIRY CREAMER | 1-50 TPH | PIGMENTS | 1-40 TPH |

| SPICES | 1-40 TPH | POLYMER BEADS | 1-250 GPM |

| STARCH | 1-50 TPH | POWDER COATINGS | 1-30 TPH |

| SUGAR | 1-120 TPH | TiO2 SLURRY | 5-250 GPM |

| TOFU | 5-200 GPM | CALCIUM CARBONATE | 1-70 TPH |

| TOFU | 20-900 LPM | MICA | 0.25-10 TPH |

| EXPANDED PEARLITE | 0.25-7 TPH | GYPSUM | 1-90 TPH |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.