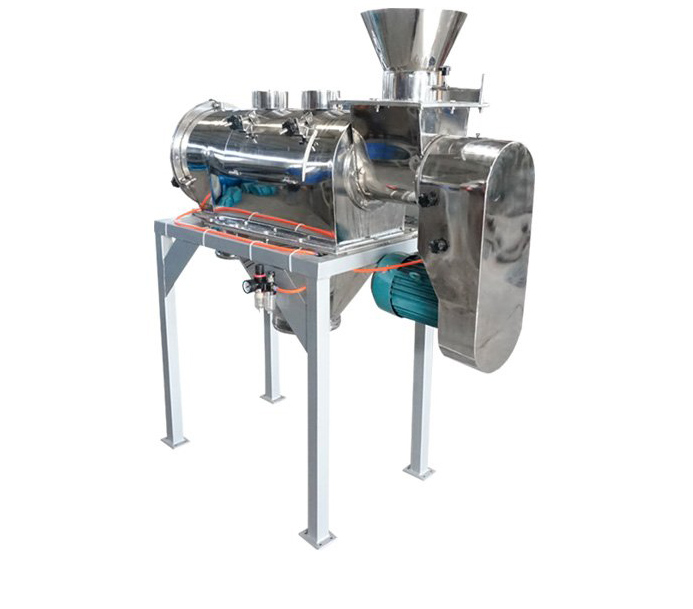

Centrifugal sifter, its working principle is centrifugal force. Rotary screening machines use screw conveyors or rotating paddles to push the product particles through the screen to screen.

The circular vibrating screen is also called a rotary screen and works on a gyroscope. Eccentric weights are applied to the top and bottom of the shaft and rotate to produce 3D movement.

vibro sifter screens products through the vibration generated by the motor, and eccentric weights are applied to the top and bottom of the shaft and rotate to produce 3D movement.

The following are the main points based on the scenario, which will explain the difference between the centrifugal sifter and the vibro sifter:

If the product has a low bulk density and light weight, a centrifugal sifter will be the most suitable machine for the screening process.

If sieved in vibro sifter, products with light weight and low bulk density will not pass easily, and will continue to move and jump the screen, because it cannot obtain the required pressure, and the screening process will not provide the required Yield.

Products or applications that need to be classified or classified into different sizes are only suitable for classification using circular vibro sifter-because they can be installed with 4 layers of screens and can provide 5 levels of classification.

The centrifugal siftermachine cannot perform classification because it can only accommodate a single-mesh screen.

3. Anti-clogging performance

Few applications and products, such as coffee, flour, soy lecithin powder, spice powder, etc., have high moisture content and are easy to agglomerate. In order to screen or screen such products, experts recommend installing a centrifugal sifter instead of a vibro sifter.

For products that are prone to agglomeration, the main reason for choosing a rotary screen instead of a circular vibrating screen is that there is less product loss. When a Centrifugal sifter is used for screening, the centrifugal force generated by the rotation of the screw conveyor causes zero product loss. In a round screen, the particles stay above the screen area and are thrown out of the outlet, resulting in product loss.

Few applications and products (such as metal powders, specialty chemicals, fragrances, etc.) have very fine particles, so it is necessary to screen the finest mesh of such products.

For the screening of fine particles, a centrifugal sifter may be the only solution, because our vibro sifter & vibro separator can screen up to 500 meshes, while the centrifugal sifter can only screen up to 530 meshes.

Today, many industries, including food, pharmaceuticals, minerals, chemicals, etc., must follow various laws, standards and laws to ensure personnel safety regulations and product quality regulations.

In industries such as food and pharmaceuticals, small pollution may seriously affect the quality of the final product and may be harmful to the end user.

In order to avoid any small pollution that may be spread by humans or air, the centrifugal siftering machine is the best choice, because if installed correctly, it can provide a completely enclosed and dust-free environment during the screening and screening process. The reason why it can provide a completely closed environment is because of its working principle. It works under centrifugal force and does not produce any vibration, so the inlet and outlet can be rigidly connected, while the circular vibrating separator works on vibration, and the inlet and outlet can only be connected flexibly, and the flexible connection increases Opportunity to leak. In the chemical, pigment, mineral and other industries, hazardous substances are used in the manufacturing process. Inhalation or direct contact with these substances may cause danger to operators and laborers working there. Therefore, for sieving or screening, industry experts recommend a fully enclosed system of this material.

Some industries also follow safety regulations and only allow machines to generate noise up to the standard DB. Industries and companies that follow such regulations in accordance with safety laws should always consider centrifugal sifter as their first choice because their noise level is lower than 80DB, enabling noise-free operation.

If you still have any questions or questions, please contact our product experts directly. Call or sale@xxdahan.com.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.