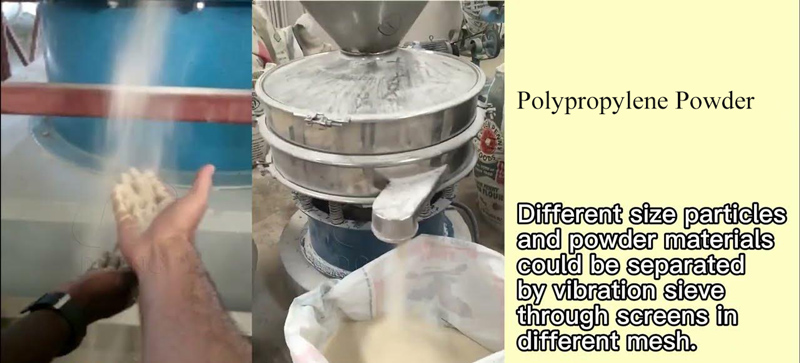

Vibrating sieve is a commonly used screening equipment, which is mainly used for particle size classification and particle screening of materials. In the use of vibrating sieves, choosing the appropriate screen material is of great significance to ensure the efficient screening of vibrating sieves. Polypropylene powder is a common powder material. Polypropylene powder usually has a fine particle size range, so it needs to be screened during production to ensure product quality and consistency.

When sieving polypropylene powder, the choice of mesh size depends on the specific application and desired particle size distribution. Here are some common mesh sizes that are often used for sieving polypropylene powder:

40 mesh (0.425 mm): This mesh size allows larger particles to pass through while retaining finer particles. It provides a coarse sieving option for applications that require larger particle size distribution.

60 mesh (0.25 mm): This mesh size offers a medium-level sieving capability, suitable for applications that require a balance between coarse and fine particle size distribution.

80 mesh (0.18 mm): This mesh size provides a finer sieving option, allowing for the separation of smaller particles. It is commonly used for applications that require a finer particle size distribution.

100 mesh (0.15 mm): This mesh size further refines the sieving process, allowing for the separation of even smaller particles. It is suitable for applications that require a fine particle size distribution.

120 mesh (0.125 mm): This mesh size offers a finer sieving option, allowing for the separation of very fine particles. It is commonly used when a high level of precision in particle size distribution is required.

It's important to note that these mesh sizes are just examples, and the actual mesh size selection may vary depending on the specific requirements of the application, desired particle size range, and the equipment available. It is recommended to consult with equipment suppliers or conduct trials to determine the optimal mesh size for sieving polypropylene powder in a particular application.

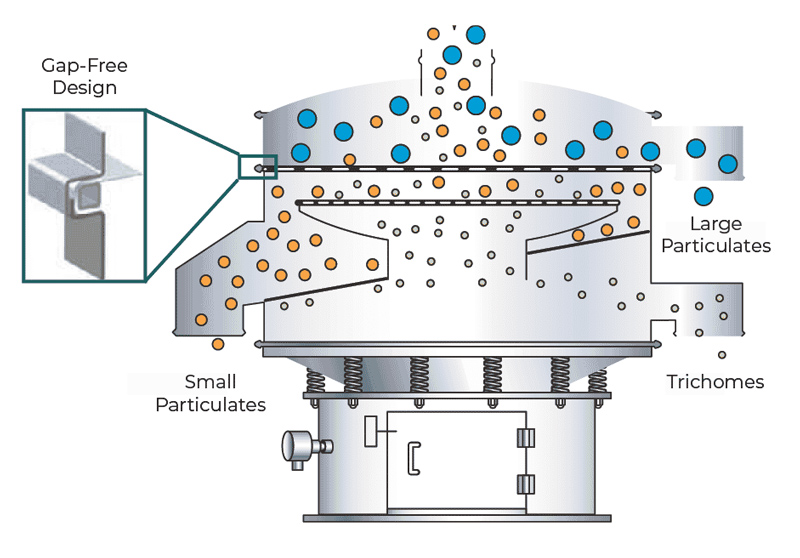

The working principle of Polypropylene powder for vibrating sieve is based on the effect of vibration force. When the vibrator starts, the vibration force generated by the motor is transmitted to the screen body to make it vibrate. After the materials on the screen body are excited by the vibration force, they will move and collide on the screen to realize the screening operation. Specifically, after the polypropylene powder enters the sieve body, the polypropylene powder with a larger particle size will be blocked on the sieve through the aperture on the sieve, while the polypropylene powder with a smaller particle size will fall through the sieve to the bottom of the sieve. in the collector. In this way, the polypropylene powder can be classified and separated according to different particle sizes through a vibrating sieve.

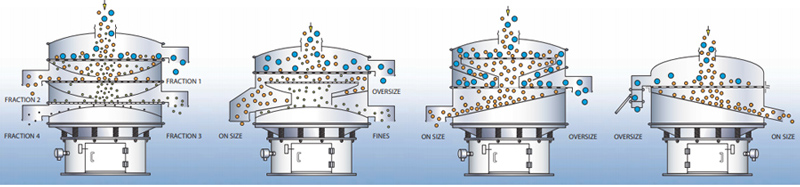

Sieving: Polypropylene powder for vibrating sieve can sieve polypropylene powder according to different particle sizes to realize particle size classification and grading.

Separation: Through polypropylene powder for vibrating sieve, polypropylene powder with different particle sizes can be separated to achieve the purpose of precise control and adjustment of particle size.

Increased production capacity: Polypropylene powder for vibrating sieve has a large processing capacity and can process polypropylene powder of multiple particle sizes at the same time, improving screening efficiency and production capacity.

Improve product quality: Through the sieving operation of polypropylene powder for vibrating sieve, impurities and uneven particles in polypropylene powder can be removed to improve product quality and consistency.

High-efficiency screening ability: Polypropylene powder for vibrating sieve, through the action of vibration force, makes the sieve body generate high-frequency vibration, thereby promoting the movement and collision of polypropylene powder on the sieve. This efficient screening method can quickly and accurately separate and classify polypropylene powders of different particle sizes, improving screening efficiency.

Large processing capacity: Polypropylene powder for vibrating sieve adopts multi-layer screen design, which can process polypropylene powder of multiple particle sizes at the same time. This design enables the vibrating screen to handle a large amount of materials, increase production capacity, and is suitable for large-scale production.

Adjustable screening accuracy: The amplitude and frequency of Polypropylene powder for vibrating sieve can be adjusted, so that the ability of particles to penetrate the screen during the screening process can be controlled. By adjusting the amplitude and frequency, precise sieving particle size control can be achieved to meet the requirements of different products.

Simple structure and convenient operation: Polypropylene powder for vibrating sieve has a relatively simple structure, consisting of a sieve body, a vibrator, and a screen. This design makes the vibrating sieve easy to operate and easy to maintain. At the same time, the vibrating screen can also be customized according to needs to meet different production requirements.

Improve product quality: Polypropylene powder for vibrating sieve can remove impurities and uneven particles in polypropylene powder, improving product quality and consistency. Through the screening operation, it can ensure that the product meets the predetermined size requirements and improve its market competitiveness.

In short, polypropylene powder for vibrating sieve realizes the screening and separation of polypropylene powder through the action of vibration force, which improves product quality and production efficiency. Polypropylene powder for vibrating sieve has the advantages of efficient screening capacity, large processing capacity, adjustable screening precision, simple structure, convenient operation and improved product quality. Its complex structure and unique working principle make it one of the commonly used equipment in solid material screening.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.