Gypsum powder rotary for vibrating screen is a professional equipment for screening gypsum powder. Gypsum powder is an important building material, widely used in construction, decoration, medicine and other fields. Rotary vibrating screen can efficiently screen gypsum powder, improve production efficiency and ensure product quality.

It feeds the gypsum powder into the screen by means of rotational vibration, and uses the mesh of the screen to separate the gypsum powder of different particle sizes. Gypsum powder rotary for vibrating screen is also suitable for screening various gypsum powders, such as building gypsum, industrial gypsum, medical gypsum, etc.

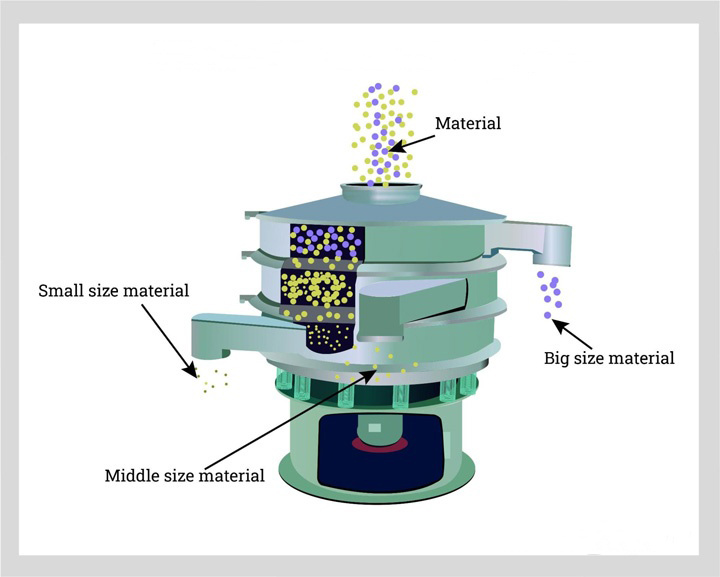

The structure of the gypsum powder rotary for vibrating screen is relatively simple, mainly composed of several parts such as a screen frame, a double-layer vibrating motor, a suspension beam and a coordinate instrument. The screen frame is the core component of the screen, usually made of stainless steel, which is durable. The double-layer vibration motor is the power source of the sieve machine, which pushes the gypsum powder to the sieve surface through the vibration force to realize the sieving effect. The suspension beam plays the role of supporting the screen frame to ensure the stable operation of the screen machine. The coordinate instrument is used to monitor the operation of the vibrating screen, and can record the vibration parameters in real time, which is convenient for adjustment and maintenance.

When using the gypsum powder rotary for vibrating screen for sieving operation, the gypsum powder is first put into the screen frame from the hopper. The vibration force of the double-layer vibrating motor pushes the gypsum powder to the screen surface, and at the same time, due to the ventilation holes above the screen surface, the dust is sucked away through the ventilation holes, so as to keep the screen surface clean. The gypsum powder particles gradually pass through the sieve holes according to the particle size, and the particles with different particle sizes are screened into different levels. The sieve hole size on the sieve can be adjusted as needed to meet the requirements of different particle sizes.

1. Efficient screening: Through the continuous vibration and rotation of the screen, the gypsum powder can be effectively screened according to different particle sizes to improve the screening efficiency.

2. Uniform distribution: During the screening process, the materials will be evenly distributed on the screen surface, avoiding the situation that some large particles of materials block the screen or get too close.

3. Simple operation: The operation of the gypsum powder rotary for vibrating screen is relatively simple, just put the material into the funnel mouth, turn on the vibrating device to start screening.

4. Energy saving: Due to the reasonable design of the gypsum powder rotary vibrating screen, the required vibration force is small, which can save energy and reduce operating costs.

However, there are also some shortcomings in the gypsum powder rotary for vibrating screen. First of all, due to the effect of vibration force, the finer gypsum powder particles are prone to clogging during the screening process. Secondly, since the moving track of the particles in the screening process is rotary, it will cause a certain amount of material loss. Again, a large amount of energy needs to be consumed during the operation of the vibrating screen, and the waste of energy is relatively serious.

To sum up, the gypsum powder rotary for vibrating screen is an efficient, simple, energy-saving and convenient gypsum powder screening equipment, which is widely used in the production and processing of gypsum powder. It can classify gypsum powder according to needs, improve production efficiency and ensure product quality. However, it also needs continuous improvement and optimization to improve some problems in the screening process and further improve the performance and use effect of the equipment.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.