Automatic powder sifter

Automatic powder sifter Stainless steel automatic powder sifter

Stainless steel automatic powder sifter Automatic powder sifter with dust-free dosing station

Automatic powder sifter with dust-free dosing station Mobile automatic powder sifter

Mobile automatic powder sifter Industrial automatic powder sifter

Industrial automatic powder sifter

Removes foreign matter and agglomerates from any powder

![]()

![]()

![]()

Price:$760.00-$3,090.00/Set

Consult now and enjoy a 10% discount

Diameter: 600-1500mm

Screen size: 5-100 mesh

Capacity: 0.1t/h-10t/h

Power: (0.1-0.4)*2kw

Noise: below 70 decibels

Application: For safety screening and inspection screening of powders, such as flour, food powder, pharmaceutical powder, chemical powder, metal powder, etc., to improve product quality of materials before packaging

Commitment:

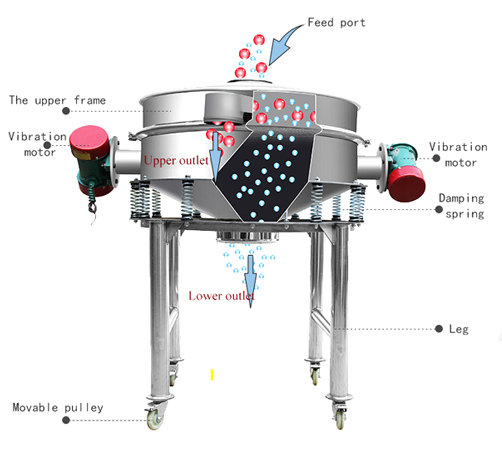

Automatic powder sifter is mainly used in the feeding system at the front end of the powder production line. It can separate foreign objects in powder raw materials (flour, starch, milk powder). Because it is connected in series in the system and automatically separates foreign objects, it can replace manual observation and separation of foreign objects. check action. Since the bottom outlet of the machine is placed directly below the top inlet, the residence time of the material on the screen surface is reduced, the material can be discharged faster, and its screening capacity is greatly increased.

Automatic powder sifter is suitable for impurity removal and grading of various powder materials, such as flour, starch, milk powder, quartz powder (sand), fluorescent powder, feldspar powder, fly ash, rice flour, soybean powder, egg powder, pharmaceutical powder, pearl powder , resin powder (PVC, epoxy), washing powder, rubber powder, coating powder, alloy powder, gold powder, silver powder, copper powder, aluminum powder, nickel powder, chromium powder, magnesium powder, zinc powder, barium powder, vanadium powder, Titanium powder, strontium powder, lead powder, etc.

Automatic powder sifter can be installed under bulk silos for safe sifting of powders, or pneumatically conveyed from tanker or railcar receiving operations to check incoming material after delivery, and can also be installed in bakeries of all sizes and food processing plants. In addition, the automatic powder sifter can be used in conjunction with a feeding station (dust-free feeding station) to unload and inspect small or extra large bags of powder to avoid dust problems in sifting.

Remove impurities and improve quality

The product is poured into the sifter, where impurities and oversized contaminants are removed before the flour passes through the screen to the rest of the line, ensuring the safety, hygiene and quality of the final product.

Large output

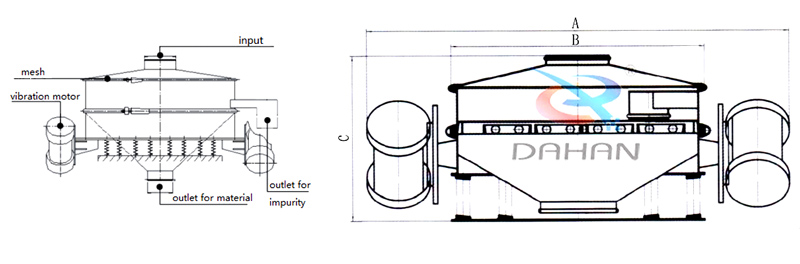

The water inlet and outlet are designed in the same vertical direction, so that the material can be discharged directly and reduce the residence time of the material on the screen surface. Its processing capacity is 2-5 times that of ordinary vibrating screen.

Polished design, not easy to hang powder

Made of SUS304 or 316L stainless steel, this sieve is mirror polished with a 0.1-0.2RA internal and external surface finish, designed to meet the stringent engineering and safety standards required by the powder industry.

Sealing system

The fully enclosed structure eliminates the problem of dust in the air. It can be used directly in series in the pipeline to remove foreign matter and impurities in the pipeline, and can also be used directly with the vacuum feeder to achieve negative pressure and dust-free operation.

Easy to clean

The machine can be disassembled quickly without any tools and is easy to clean, thus increasing productivity and avoiding any chance of cross-contamination between batches.

Small footprint

The compact size meets industrial and commercial needs with minimal headroom and floor space, and can fit comfortably into any production line.

Automatic powder sifter for sieving lime powder

Automatic powder sifter for sifting turmeric powder (with dust-free feeding station)

| model | power(mm) | Screen diameter(mm) | Effective area(㎡) | volume(mm) |

| ZPS-600 | 0.12 | 520 | 0.2124 | 740*600*500 |

| ZPS-800 | 0.18 | 720 | 0.4072 | 1010*800*600 |

| ZPS-1000 | 0.18 | 890 | 0.6221 | 1200*970*640 |

| ZPS-1200 | 0.25 | 1090 | 0.9331 | 1430*1170*790 |

| ZPS-1500 | 0.55 | 1390 | 1.5175 | 1780*1470*760 |

1. Screening hand-fed ingredients from bags: The bag dump platform can be set at a comfortable height for the operator to support the height of the bag. The dust cover reduces dust during the screening process, eliminating the need for flexible materials and improving hygiene efficiency. Below the mesh is a magnetic trap that traps iron particles smaller than the mesh size,

2. Dust-free screening conveying system: The powder can be pneumatically conveyed and inspected and screened from the storage location to your next process stage.

3. Screw conveying and screening system: the powder is evenly fed into the screen from storage equipment such as silos.

ZPS-1000 automatic powder sifter, 24 mesh, is used to sieve wheat flour for instant noodles, to remove impurities and increase the specific surface area of wheat flour, which can reach 350kg/150 seconds.

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Wheat starch | 1 | 250 | DH-1200-1S | Wet | 3200 IT |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 IT |

| Salt | 1.2 | 30/80 | DH-1500-1S | Dry | 5000㎏ |

| Medicine powder | 0.8 | 80 | DH-800-1S | 550㎏ | |

| Medicine powder | 0.8 | 80 | DH-800-1S | 550㎏ | |

| Lead powder | 11.34 | 10/80 | DH-1000-2S | 1000㎏ | |

| Iron powder | 3 | 400 | DH-800-1S | 230㎏ | |

| Emery | 4 | 60 | DH-1000-1S | 300㎏ | |

| Aluminum powder | 0.9/1.2 | 80/120 | DH-800-2S | 350㎏ |

According to the customer's upstream and downstream products and site space, modify the equipment size, customize the equipment structure, and meet the customer's needs. Dahan automatic powder sifter can be designed and manufactured according to the user's requirements, such as raising the feed port and installing butterfly valves at the discharge port.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.