The vibrating screen is a commonly used screening equipment, which is widely used in the classification and screening of granular materials. Its main working principle is to make the particles move relative to each other on the screen through vibration, so as to realize the separation of particles of different sizes.

Coarse sieving: A larger mesh is usually selected, generally between 10 and 100 mm.

Fine screening: Choose a medium to smaller mesh as needed, generally between 0.1 and 10 mm.

However, the specific mesh selection still needs to be adjusted and optimized according to the actual situation and screening requirements. In practical applications, experiments and adjustments can be made to find the most suitable mesh size to achieve the desired screening effect.

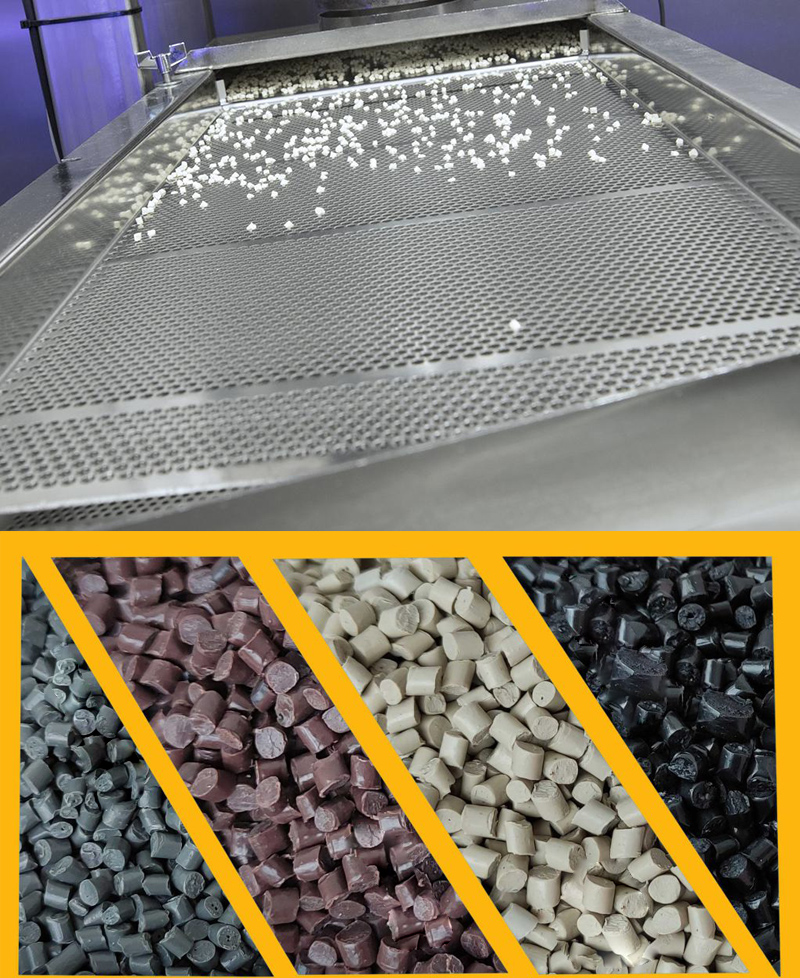

Screening and Classification: Used for screening and classification of ceramic particles. Through the movement of the vibrating screen, ceramic particles are separated and classified according to different particle sizes. This is very important for ceramic products where particle size consistency needs to be ensured during the production process.

Impurity removal and impurity screening: During the production process of ceramic particles, impurities or other unwanted substances may be present. Vibrating screens can remove these impurities from ceramic particles through screening operations, improving product quality and purity.

Post-crushing screening: During the preparation of ceramic granules, it may be necessary to crush or crush the material. Vibrating screens can be used to sieve crushed ceramic particles to obtain the desired particle size distribution and particle size.

Recycling and reuse: During the production and processing of ceramic particles, some waste or by-products may be generated. Vibrating screens can be used to recycle and reuse these ceramic particles, reducing resource waste and environmental impact.

Ceramic particle for vibrating screen is mainly used to achieve particle size classification and screening of materials. It can divide materials into different grades according to particle size, so as to meet the needs of different application fields. Ceramic particle for vibrating screen is widely used in chemical industry, metallurgy, food, pharmaceutical and other industries to screen powdery and granular materials, such as ore, coal, fertilizer, food raw materials, etc.

Wear resistance: Ceramic particle vibrating screens are usually made of ceramic materials with strong wear resistance, such as alumina, zirconia or silicon carbide. These ceramic materials have excellent wear resistance and can maintain a long service life when handling materials containing abrasive particles.

High temperature tolerance: Able to work in high temperature environments and adapt to the screening needs of high temperature ceramic particles. Ceramic materials have good high temperature resistance and can maintain stable screening performance under high temperature conditions.

Corrosion resistance: Ceramic materials have strong corrosion resistance to many chemicals and corrosive media. This enables the vibrating screen to have superior corrosion resistance when handling corrosive materials and maintain a stable screening effect.

High screening efficiency: Ceramic particle vibrating screen has a smooth surface and precise pore size. This makes the screening process more efficient, enables accurate separation and screening, and improves screening efficiency.

Reduce clogging and adhesion: Ceramic materials have smooth surface properties and are less prone to clogging and adhesion. This makes the ceramic particle vibrating screen perform well when dealing with ceramic particles that are prone to clogging or bonding, and can maintain continuous screening capabilities.

Customization and diversity: Ceramic particle vibrating screens can be customized and designed according to the needs of specific applications, including the selection of different ceramic materials, mesh sizes and screen structures. This enables the ceramic particle vibrating screen to adapt to different screening requirements and material characteristics.

| Applications | Product | Mesh size | Capacity | Recommended models |

| Ceramic tile production | Ceramic powder | 60-200 | 10-20 tons/hour | DZSF-1030 |

| Ceramic particle classification | ceramic particles | 40-120 | 5-8 tons/hour | DZSF-612 |

| Ceramic material screening | Ceramic powder | 100-325 | 3-5 tons/hour | DZSF-525 |

| Ceramic particle removal | ceramic particles | 20-80 | 2-4 tons/hour | DZSF-520 |

| Ceramic particle sorting | Ceramic particles of different colors | 60-200 | 1-2 tons/hour | DZSF-515 |

In general, the main uses of vibrating screens in ceramic particles are screening, classification, impurity removal, sorting and separation. They play a key role in the ceramic industry, helping to improve product quality, reduce production costs, and meet the requirements of different applications. If you have any screening or filtration plans, you can contact Dahan Machinery at any time, and our team of engineers will design a suitable screening solution for you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.