Powder sieving machine is used in various powder processing industries to remove agglomerates, coarse particles and impurities in powder, suitable for sieving flour, pharmaceutical powder, metal powder, metallurgical powder, powder coating, etc.

![]()

![]()

![]()

Price:$760.00-$5,090.00/Set

Consult now and enjoy a 10% discount

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Screen frame: 1-5 layers (3 layers is best)

Material: Q235 carbon steel, stainless steel 304 or 316L, polypropylene plastic

Motor power: 0.25Kw to 2.2Kw or customized

Application: Provide accurate and efficient particle size separation, suitable for screening various food powders, pharmaceutical powders, metal powders, powder coatings and other powders

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Powder sieving machine, also known as a powder vibrating sieve or powder sifter, is a device used to separate and classify fine powder particles based on their particle size. It is commonly used in industries such as pharmaceuticals, chemicals, food processing, and cosmetics.

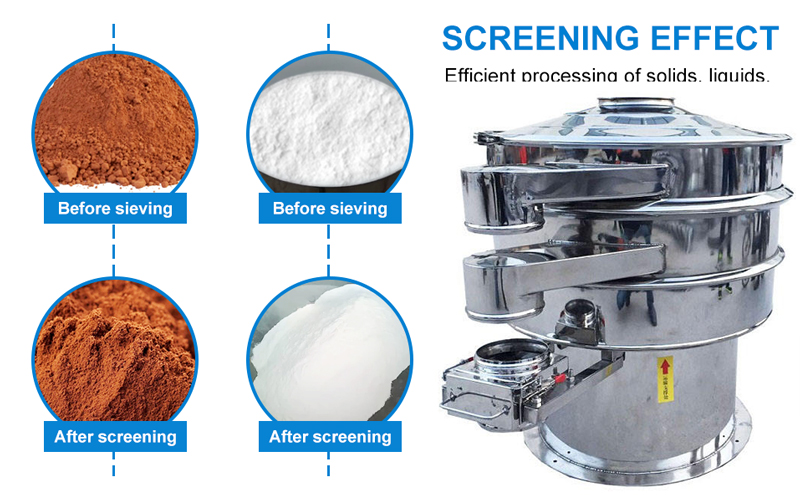

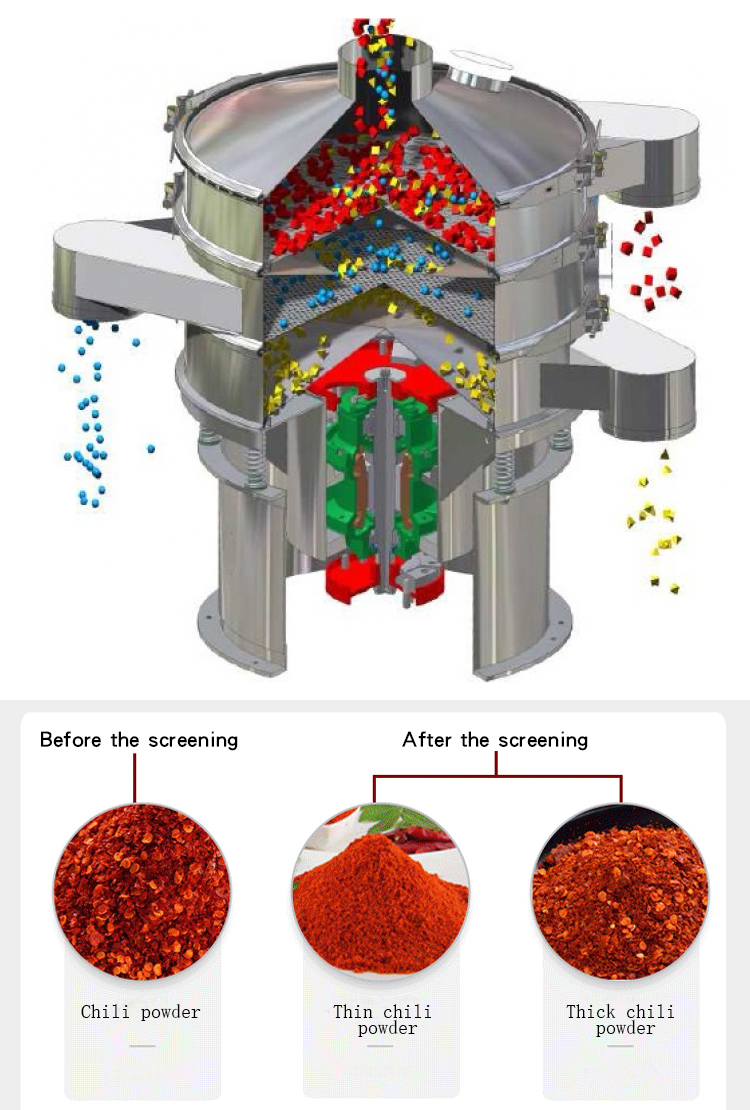

The main function of a powder sieving machine is to pass the powder material through a vibrating screen or sieve deck that contains specific mesh openings. The vibration provided by the machine causes the powder particles to move and pass through the openings, separating them based on their size. The finer particles pass through the sieve, while the larger particles are retained on the sieve surface.

The purpose of the powder sieving machine is to separate and classify the fine powder particles according to their particle size. It plays a variety of important roles in various industries:

Particle Size Classification: Used to classify powder particles into fractions of different sizes. By using different mesh screens, the machine can separate the powder into the required particle size range. This classification is critical to ensuring consistent product quality and meeting the specific requirements of industries such as pharmaceuticals, chemicals and food processing.

Quality Control: They help ensure that powder particles meet the required size specifications and are free of oversized or undersized particles. Sieving machines help maintain product consistency and quality by removing impurities and ensuring an even particle size distribution.

Removal of oversized particles: In some applications, it is important to remove oversized particles or agglomerates from powders. Screening machines can effectively separate these larger particles before they can cause problems in subsequent processing steps or affect the properties of the final product.

Powder Conditioning: Sieving machines can be used to improve the flow characteristics of powders. By breaking up agglomerates and ensuring a more uniform particle size distribution, the sieving process enhances powder flowability, facilitating handling, packaging and further processing.

Vibro Sifter

A wide range of powders can be sieved, dusted and classified, eliminating any unwanted solids and ensuring consistent and reliable handling. We can offer screening machines in a variety of single- or multi-layer configurations for batch or continuous processing.

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Ultrasonic Vibrating Screen

Ultrasonic deblinding systems are used to eliminate mesh blindness when screening difficult powders, using ultrasonics allows you to sieve on a 20μm mesh, making it easier to separate fine powders such as metal powders, paints, chemicals or food powders.

Mesh Size: 10-635 mesh

Capacity: 1-5t/h

Direct Discharge Sifter

It can carry out simple safety screening and precise classification of powder or granules. The more common applications are production lines for flour, washing powder, rice flour, graphite powder, metal powder, etc.

Mesh Size: 140 mesh

Capacity: 3-30 tons/hour

Efficient particle size separation

Provides efficient, precise particle size separation. By using sieves with specific mesh sizes, they can accurately separate powder particles into fractions of different sizes. This ensures that the desired particle size range is achieved, helping to improve product quality and consistency.

Improve productivity

The productivity in the manufacturing process can be significantly improved. They can screen at high speeds and can handle large volumes of powdered material, increasing productivity and reducing processing time.

Improve product quality

Removes oversized particles, impurities and agglomerates from powders to help ensure product quality and consistency. This helps prevent clogging, uneven mixing and poor product performance. By achieving a uniform particle size distribution, sieving machines help produce high-quality products.

Improve process efficiency

Incorporating a powder sifter into a production line optimizes overall process efficiency. They simplify material handling, improve powder flow characteristics, and reduce the need for manual screening or rework. This results in smoother production operations, less downtime and higher throughput.

Easy to maintain and clean

Easy to maintain and clean. They usually have removable screens or frits that can be quickly replaced or cleaned. This promotes hygiene, prevents cross-contamination and facilitates efficient equipment maintenance.

Cut costs

By precisely separating particles and removing impurities, powder sifters help minimize waste and optimize material usage. This saves money by reducing the need to rework or reject non-conforming material. The increased productivity and efficiency of screening machines also contribute to overall cost savings in the production process.

Powder screening machine is mainly composed of vibrator, screening box, screen and other parts. When working, the vibrator generates vibration force in different directions to make the material be screened in the screening box. After the material passes through the screen, it is divided into different particle sizes and falls into different collectors.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Powder sieving machines have a wide range of applications across various industries. Some common applications include:

Pharmaceutical Industry: Powder sieving machines are extensively used in the pharmaceutical industry for quality control and ensuring uniformity of powdered medications. They help separate and classify active pharmaceutical ingredients (APIs), excipients, and other powders used in drug manufacturing.

Chemical Industry: Powder sieving machines play a crucial role in the chemical industry for sieving and classifying various types of powders, including pigments, dyes, catalysts, polymers, and fine chemicals. They help ensure consistent particle size distribution and purity of chemical products.

Food Processing Industry: In the food industry, powder sieving machines are used for separating and grading powdered ingredients such as flour, sugar, spices, cocoa powder, and food additives. They help remove contaminants, achieve desired particle sizes, and ensure product quality and safety.

Cosmetics Industry: Powder sieving machines are utilized in the cosmetics industry for sieving and refining cosmetic powders, including face powders, talcum powders, and eyeshadows. They help achieve a smooth texture, uniform particle size, and eliminate clumps or impurities.

Metal Powders Industry: Powder sieving machines are used in the production of metal powders, such as aluminum, iron, and stainless steel powders. They help classify the metal particles according to size specifications for various applications, including additive manufacturing (3D printing), powder metallurgy, and surface coatings.

Ceramics Industry: Powder sieving machines are employed in the ceramics industry to separate and classify ceramic powders, including clay, feldspar, silica, and other raw materials. They help achieve the desired particle size distribution for forming ceramic bodies and glazes.

Paints and Coatings Industry: Powder sieving machines are used for sieving and grading powdered pigments, fillers, and additives in the paints and coatings industry. They ensure uniform dispersion of particles and help control the paint's color, texture, and consistency.

Battery Industry: Powder sieving machines are utilized in the battery industry for sieving electrode materials, such as lithium-ion battery powders. They help maintain consistent particle size distribution, improve electrode performance, and ensure battery quality.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.