Powder coating ultrasonic sieving machine is a vibrating screen equipment specially designed for powder coating screening. It solves the problem of static electricity, slow passing through the screen, easy blocking of the screen, low efficiency and poor screening effect when the powder coating is screened with an ordinary vibrating screen. And other problems, the vibration frequency of 36,000 times per minute can make the powder coating quickly pass through the screen, prevent the screen from clogging, and prolong the service life of the screen.

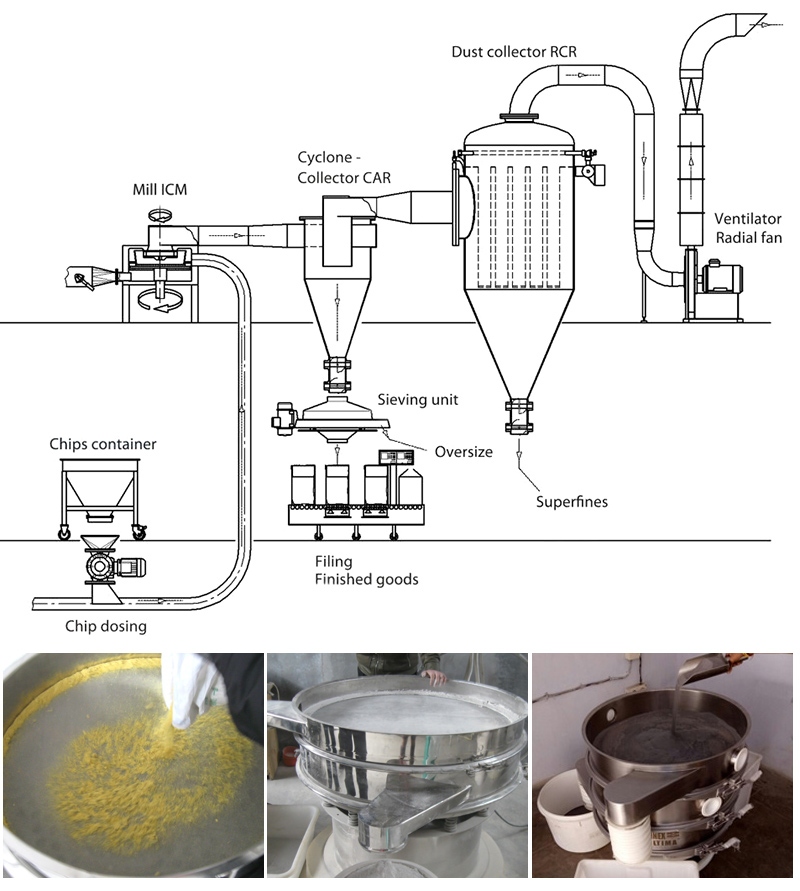

1. To remove large particles in the coating that exceed a certain specification, generally 40 mesh, 60 mesh and 80 mesh are used.

2. To remove the ultrafine powder in the finished material, 300 mesh, 325 mesh national standard screen is generally used for screening, and ultrasonic screening is usually used, which can effectively solve the problem of melting and agglomeration in coating screening.

Powder coating ultrasonic sieving machine can convert 220v, 50HZ or 110v, 60HZ electric energy into 18KHZ high-frequency electric energy, input the ultrasonic transducer, so as to turn it into 18KHZ mechanical vibration, this system is based on the traditional vibrating screen On the screen, a low-amplitude and high-frequency ultrasonic vibration wave or mechanical wave is introduced on the screen, so that the ultra-fine powder in the material receives a huge ultrasonic acceleration, so that the material on the screen always maintains a suspended state, which solves the problem. Strong adsorption, easy agglomeration, high static electricity, high precision, high density, and other intractable diseases in the screening process make the screening of ultra-fine powder no longer difficult.

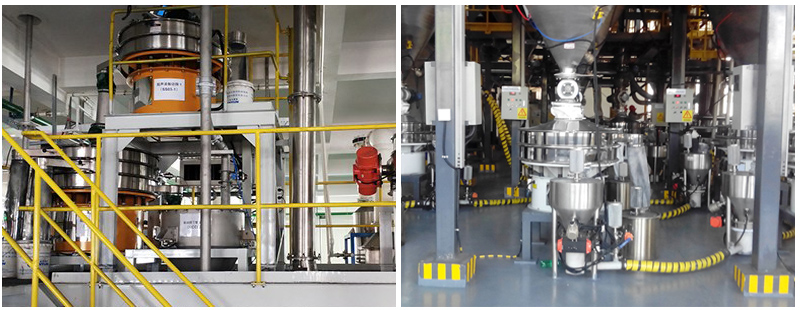

1. The high-frequency vibration of the ultrasonic system makes the powder coating in a low-altitude suspension state during the screening process.

2. Since the screen will not be blocked, the screen can be cleaned without stopping the machine, and the output can be increased by 10 times.

3. No need to shut down to clean the screen, reduce the risk of downtime and reduce production costs.

4. Explosion-proof vibration motor, fully enclosed structure, can prevent powder coating from dust explosion due to large dust content during screening.

| Model |

Diameter (mm) |

Screening area (m2) |

Screen size target |

Layers |

Input power (V/HZ) |

Ultrasound model |

Transducer location |

Frequency (KHz) |

Ultrasound gear |

Power (Kw) |

| DHC-200 | ⌀200 | 0.03 | 10-1200 | 1-5 | 220/50 | DHC-7 | External | 38KHz |

Continuous 1-9 gears Pulse 2 gear |

0.18 |

| DHC-400 | ⌀340 | 0.09 | 1-3 |

Sieving machine 380/50 Ultrasonic sieving machine220/50 |

Built-in/External | 0.25 | ||||

| DHC-600 | ⌀540 | 0.23 | 0.55 | |||||||

| DHC-800 | ⌀730 | 0.42 | 0.75 | |||||||

| DHC-1000 | ⌀900 | 0.64 | 60-635 | 1.1 | ||||||

| DHC-1200 | ⌀1100 | 0.95 | 1.5 | |||||||

| DHC-1500 | ⌀1400 | 1.54 | 2.2 | |||||||

| DHC-1800 | ⌀1700 | 2.27 | 3 |

Address::China,Yanjin county forest park gate to the west 1000 meters north road.