Used for screening and grading of washing powder, effectively removing impurities.

![]()

![]()

![]()

Price:$420.00-$600.00/Set

Consult now and enjoy a 10% discount

Function: Filter\screening\separation\sorting\sieving

Mesh size: 2-500 Mesh

Capacity: 100-3300kg/h

Sieve diameter: 520-1390mm

Voltage: 220V/380V or as your request

Material: Stainless Steel 304/316L

Application: Detergent powder sieving machine is mainly used to screen washing powder raw materials, such as washing powder particles, additives, pigments, etc.

Commitment:

After the washing powder is granulated, due to the adhesion of some washing powder particles to form pseudo-agglomerates, it is necessary to remove the particles and agglomerates that do not meet the size before filling, so at this time, a sieving machine is needed to solve such screening. Difficult, Detergent powder sieving machines can remove contaminants in laundry detergents such as oversized or agglomerated particles that can appear after the mixing and blending process and affect the final quality of the product.

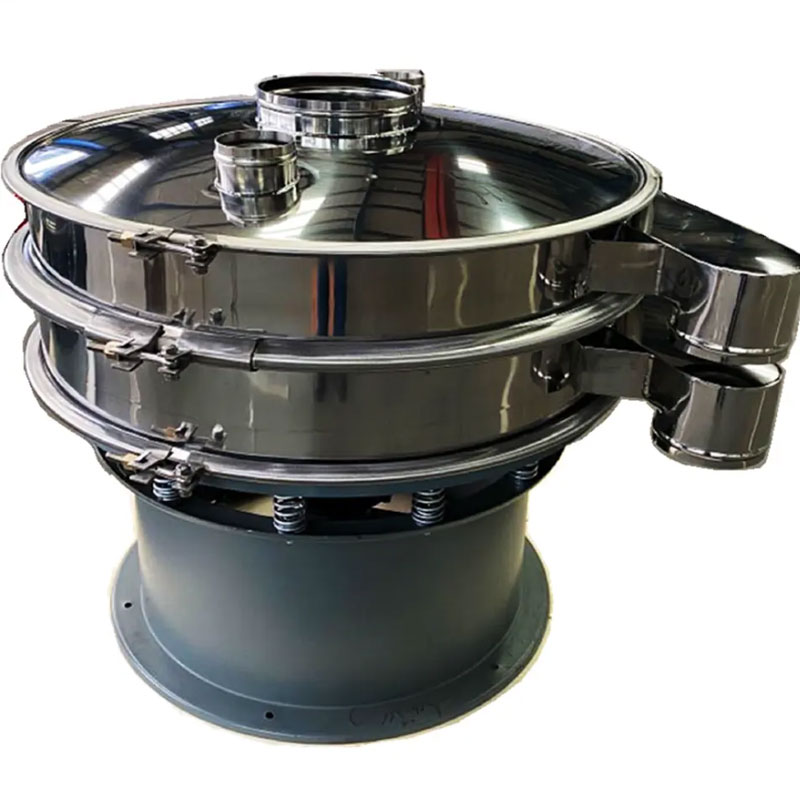

The detergent powder sieving machine is a kind of equipment specially used for sieving and grading in the production process of washing powder. Its main function is to sieve the washing powder raw materials, remove impurities and grade them to obtain washing powder particles that meet the requirements. It is usually made of stainless steel to ensure the hygiene and quality of the washing powder. At the same time, the size and shape of the screen will also be adjusted and customized according to the particle size requirements of the washing powder.

The following are specific industry application scenarios:

Washing powder production line: Detergent powder sieving machine is one of the essential equipment in the washing powder production line. It is used to screen and grade the particle size of washing powder raw materials to ensure the quality and consistency of the product.

Detergent production: In addition to washing powder, detergent powder sieving machine is also suitable for the production of other detergents, such as laundry detergent, laundry soap, etc.

Chemical industry: Detergent powder sieving machine is also used in the chemical industry. It can be used to screen and grade granular chemicals, such as powdered pigments, granular additives, etc.

Food industry: Detergent powder sieving machine also has certain applications in the food industry. It can be used to screen and grade food additives, seasonings, starch powder, etc.

Detergent powder sieving machine whether to use single or double is mainly related to the equipment and output size. The motor is located on one side of the machine. After the material enters the screen surface, it is subjected to the force of the vibration source to make an elliptical motion track on the screen surface, and then quickly and reciprocatingly completes the process. While the net is moving, the material is quickly stripped, broken up and reorganized. The discharge port is directly below the sieve, and the material can quickly pass through the net and be discharged. It is suitable for the removal of impurities for materials with little on the screen.

The washing powder sifter plays an important role in the production process of washing powder. Through its efficient screening function, it can improve production efficiency, product quality, reduce costs, and also benefit environmental protection and improve workplace safety. Here are some benefits of washing powder sifter:

1. Improve the quality of the finished product by removing the agglomerates and large particles in the detergent powder.

2. The inlet and outlet are designed in the same vertical direction, and the large flow outlet at the bottom enables the material to be discharged directly. The discharge speed is fast, and the output is 2-5 times that of ordinary screening machines.

3. This vibrating sieving machine can also be enclosed to provide effective dust control and protect the operator from hazardous substances.

4. Small in size, it can easily fit into the limited headroom space available in the production line without affecting the flow rate.

5. The quick release clamping system and minimal contact parts ensure that the machine can be easily disassembled and thoroughly cleaned between batches, keeping downtime to a minimum.

7. It can be directly used in the pipeline in series to remove foreign matter and impurities in the pipeline, without manual operation, and to avoid secondary pollution to materials.

| Model | Power(kw) | RMP(r/min) | Sieve diameter(mm) | A | B | C |

| ZPS-600 | 0.18 | 1460(960) | 520 | 1070 | 600 | 502 |

| ZPS-800 | 0.25 | 720 | 1390 | 800 | 525 | |

| ZPS-1000 | 0.37 | 890 | 1566 | 970 | 543 | |

| ZPS-1200 | 0.55 | 1090 | 1875 | 1170 | 814 | |

| ZPS-1500 | 0.75 | 1390 | 2226 | 1470 | 875 |

| Name | High precision 2~500 mesh washing powder screening machine |

| Model | EXZS-800 |

| strength | 0.55~0.75kw |

| Grid size | 2~500 |

| Voltage | custom made |

| Material | Carbon steel SUS304 SUS316L |

| application | Powders, granules, bulk solids, liquids |

A washing powder manufacturer introduced a detergent powder sieving machine produced by Dahan to improve production efficiency and product quality. The sieving machine can quickly and accurately classify washing powder particles, remove impurities, and ensure product purity. Customer feedback said that the new equipment not only improved the operating efficiency of the production line, but also reduced labor costs and energy consumption. Through the use of the sieving machine, the company successfully improved the quality standards of washing powder production, met market demand, and won more recognition and praise from customers.

Dahan Machinery is a professional manufacturer of washing powder sifters, committed to providing high-quality and efficient sifting equipment. Our washing powder sifters are manufactured with advanced technology and high-quality materials, with precise screening effects, stable performance and reliable quality assurance. The price of our washing powder sifters is generally between $420.00 and $600.00. At the same time, we also provide customized services, customizing sifters of different specifications and models according to customer needs. If you are looking for a reliable washing powder sifter manufacturer, please contact us, we will wholeheartedly provide you with professional consulting services and high-quality products.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.