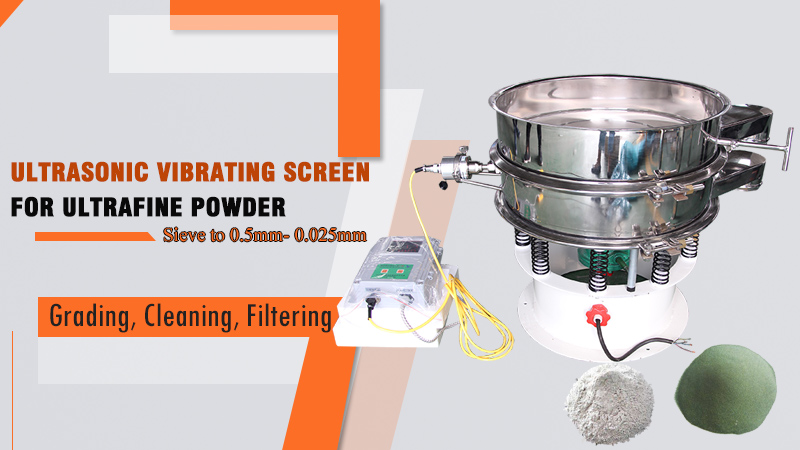

Due to the characteristics of some materials, static electricity is easily generated due to the friction between the material and the screen during the screening process, and the static electricity will make the material agglomerate and not easy to get off the screen, which causes the problem of screening. The ultrasonic vibrating screen adopts advanced ultrasonic screening technology, which can successfully solve the screening problems such as high static electricity and easy clumping, and can greatly improve the screening efficiency. Ultrasonic vibrating screen can be said to be a vibrating screen with electrostatic materials that are easy to hold together!

Which materials can be screened by ultrasonic vibrating screen?

| Material | Proportion | Mesh | Processing method |

Capacity (kg/hr IT/hr) |

| Wheat flour | 1 | 250 | Wet | 3200 IT |

| Flour | 0.6 | 24 | Dry | 1500㎏ |

| Rice flour | 0.5 0.8 | 100 | 300 ㎏ | |

| Pollen | 0.4 | 12 | 100㎏ | |

| Skimmed milk powder | 0.57-0.7 | 24 | 3000㎏ | |

| Whole milk powder | 0.57-0.8 | 12 | 1600㎏ | |

| Sugar powder | 0.5-0.8 | 100 | 200㎏ | |

| Corn starch | 0.6 | 40 | 1600㎏ | |

| Medicine powder | 0.8 | 80 | 550㎏ | |

| Polyethylene powder | 0.45 | 48/100 | 100㎏ | |

| Lead powder | 11.34 | 10/80 | 1000㎏ | |

| Copper powder | 2 | 100 | 70㎏ | |

| Iron powder | 3 | 400 | 230㎏ | |

| Aluminum powder | 0.9/1.2 | 80/120 | 350㎏ |

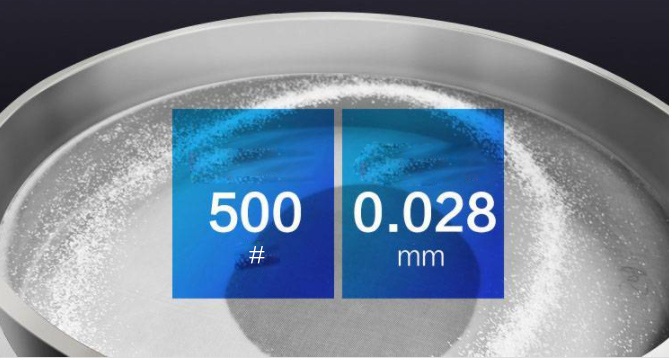

Ultrasonic vibrating screen can sieve the common dry powder particle size to 600 mesh (25μm). Such as traditional Chinese medicine powder, alumina, malt powder, cobalt powder, emery, quartz powder, alloy powder, tungsten powder, nickel powder, pigments and other materials with different dry humidity The comparison table of mesh number and processing capacity, so that users can refer to the selection of screening machines in the future:

Ultrasonic vibrating screen application materials

Ultrasonic vibrating screen is suitable for sieving of 20~300μm meshes. The effect of difficult-to-screen materials is particularly significant. The production capacity can be increased by 10 times. It can also prevent the mesh of 50~625mesh from clogging, accelerate the melting and separation of agglomerates, and then increase the sieving. Capacity, reduce the presence of large size sieves, and easily separate fine particles of adjacent diameters.

For more detailed information, please contact Dahan Machinery.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.