Ultrasonic vibrating screen is a kind of vibrating screen. This article will introduce you to the difference between ultrasonic vibrating screen and ordinary vibrating screen;

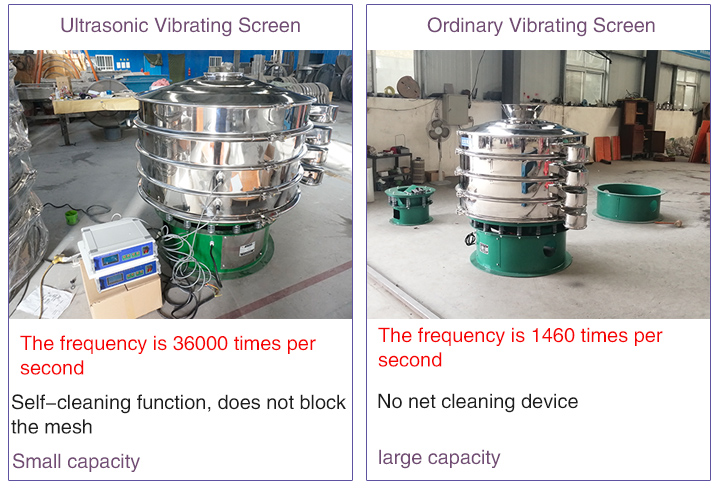

The ultrasonic vibrating screen is equipped with an ultrasonic screening system on the basis of the rotary vibrating screen. The ordinary vibrating screen has a frequency of 1,460 times per second, and the ultrasonic vibrating screen has 36,000 times per second, which truly realizes the combination of sound wave and frequency double vibration. It is this low-amplitude, high-frequency ultrasonic vibration wave (mechanical wave) that makes the ultrasonic vibrating screen suitable for separating powder with a sieve of 20 microns to 300 microns, especially for materials that are difficult to screen.

The ordinary vibrating screen does not have a screen cleaning device and does not have the function of automatic screen cleaning. Compared with ordinary vibrating screens, the ultrasonic vibrating screen adopts a unique JHC ultrasonic screening system, so the equipment does not need to add any other screen cleaning devices, and has self-cleaning The clean function mesh is not blocked.

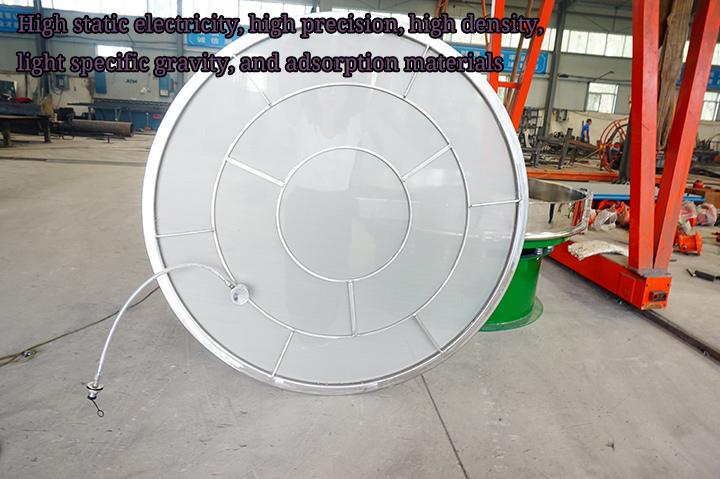

Ultrasonic vibrating screen is equipped with an ultrasonic transducer, which can speed up the separation of agglomerates, high static electricity, high precision, high density, light specific gravity, and adsorption materials, thereby increasing the weight of the vibrating screen, decomposing adhered substances, and reducing the amount of material on the screen. The screen passing rate of the vibrating screen without ultrasonic is increased by 5-20 times.

In summary, the ultrasonic vibrating screen has higher precision and output than ordinary vibrating screens, and it is not easy to block the screen, and the advantages are more significant.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.